Preparation method of phosphoric acid-doped sulfonated polymer composite membrane with self-assembled structure

A sulfonated polymer, composite membrane technology, applied in structural parts, electrochemical generators, battery pack parts, etc., to achieve good mechanical properties, stable structure, and improve electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

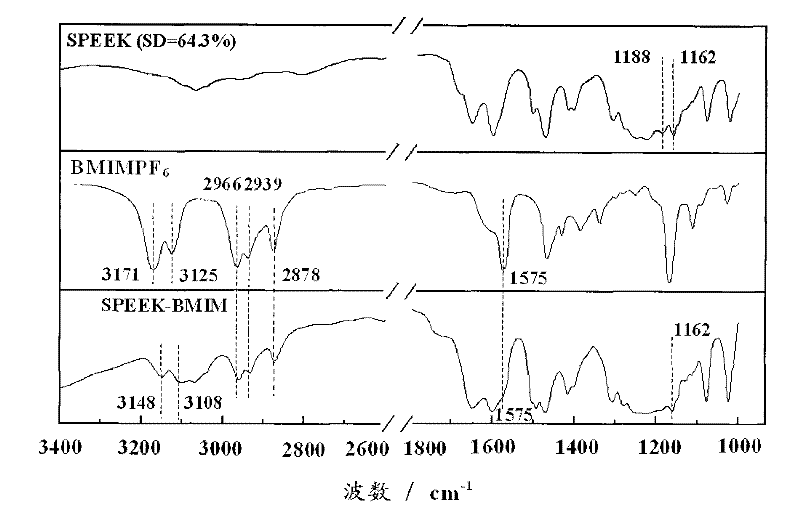

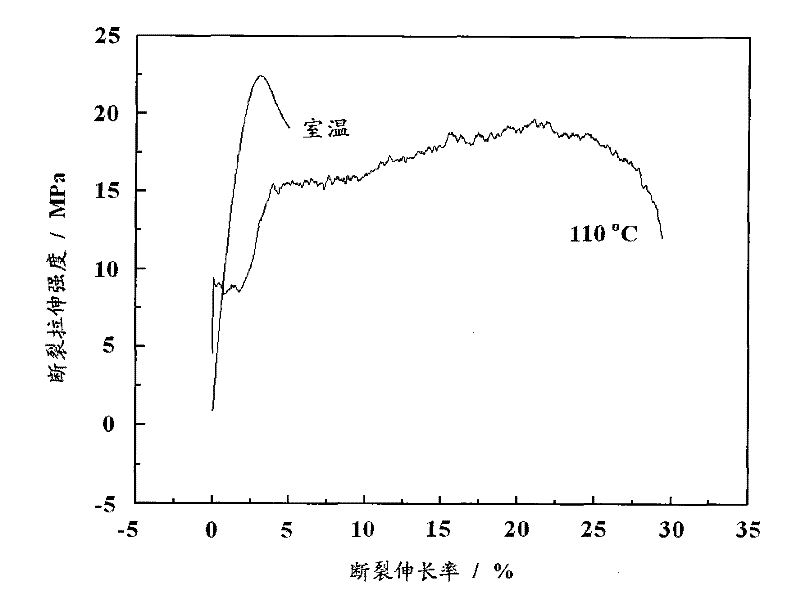

[0029] Preparation of phosphoric acid-doped ionic liquid (BMIMCl) with self-assembled structure and sulfonated polyether ether ketone composite membrane (SPEEK-BMIM / H 3 PO 4 ) method steps are as follows.

[0030] (1) Add chloro-1-butyl-3-methylimidazole (BMIMCl) into the container, soak the sulfonated polyetheretherketone (SPEEK) membrane with a sulfonation degree of 64.3% in chloro-1-butyl Base-3-methylimidazole (BMIMCl), seal the container, and place it in an oven at 120°C for 1 h.

[0031] Among them, chloro-1-butyl-3-methylimidazole (BMIMCl) is an ionic liquid. In terms of mass ratio, the ratio of sulfonated polyether ether ketone (SPEEK) to chloro-1-butyl-3-methylimidazole (BMIMCl) is SPEEK:BMIMCl=1:160.

[0032] (2) After the reaction is completed, the temperature is naturally lowered. When the temperature of the reaction system drops to room temperature, the composite film is taken out, and the liquid adsorbed on the surface of the composite film is wiped dry.

[0...

Embodiment 2

[0038] Preparation of phosphoric acid-doped ionic liquid (BMIMCl) with self-assembled structure and sulfonated polyether ether ketone composite membrane (SPEEK-BMIM / H 3 PO 4 ) method steps are as follows.

[0039] (1) Add chloro-1-butyl-3-methylimidazole (BMIMCl) into the container, soak the sulfonated polyether ether ketone (SPEEK) membrane with a sulfonation degree of 72.8% in chloro-1-butyl Base-3-methylimidazole (BMIMCl), seal the container, and place it in an oven at 100°C for 0.5 h.

[0040] Among them, chloro-1-butyl-3-methylimidazole (BMIMCl) is an ionic liquid. In terms of mass ratio, the ratio of sulfonated polyether ether ketone (SPEEK) to chloro-1-butyl-3-methylimidazole (BMIMCl) is SPEEK:BMIMCl=1:260.

[0041] (2) After the reaction is completed, the temperature is naturally lowered. When the temperature of the reaction system drops to room temperature, the composite film is taken out, and the liquid adsorbed on the surface of the composite film is wiped dry. ...

Embodiment 3

[0047] Preparation of phosphoric acid-doped ionic liquid (BMIMCl) with self-assembled structure and sulfonated polyether ether ketone composite membrane (SPEEK-BMIM / H 3 PO 4 ) method steps are as follows.

[0048] (1) Add chloro-1-butyl-3-methylimidazole (BMIMCl) into the container, soak the sulfonated polyether ether ketone (SPEEK) membrane with a sulfonation degree of 41.9% in chloro-1-butyl Base-3-methylimidazole (BMIMCl), seal the container, and place it in an oven at 130°C for 2 hours.

[0049] Among them, chloro-1-butyl-3-methylimidazole (BMIMCl) is an ionic liquid. In terms of mass ratio, the ratio of sulfonated polyether ether ketone (SPEEK) to chloro-1-butyl-3-methylimidazole (BMIMCl) is SPEEK:BMIMCl=1:60.

[0050] (2) After the reaction is completed, the temperature is naturally lowered. When the temperature of the reaction system drops to room temperature, the composite film is taken out, and the liquid adsorbed on the surface of the composite film is wiped dry. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap