Pi-shaped groove sealing ring

A sealing ring and π-shaped groove technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problem of one-way rotation of the spiral groove, and achieve the effect of reducing the degree of friction and wear, improving the lubrication state and prolonging the working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

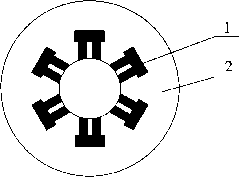

[0017] figure 1 . When the high-pressure side is on the inner diameter side of the sealing ring 2, the π-shaped groove 1 is opened on the corresponding inner diameter side, and the six π-shaped grooves 1 are evenly distributed in the circumferential direction, and the two radial linear grooves of the π-shaped groove 1 extend to the edge of the inner diameter. And a circumferential linear groove is arranged at the end away from the inner diameter.

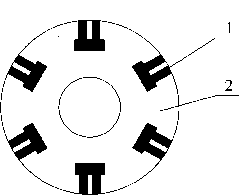

[0018] see figure 2 , when the high-pressure side is on the outer diameter side of the seal ring 2, the arrangement of the π-shaped groove 1 is opposite to that of the previous example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com