Zero-heat differential phase shift keying demodulator

A differential phase shift keying and demodulator technology, applied in optical demodulation, instruments, electromagnetic wave transmission systems, etc., can solve problems such as being very sensitive to temperature changes and unfavorable center frequency adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

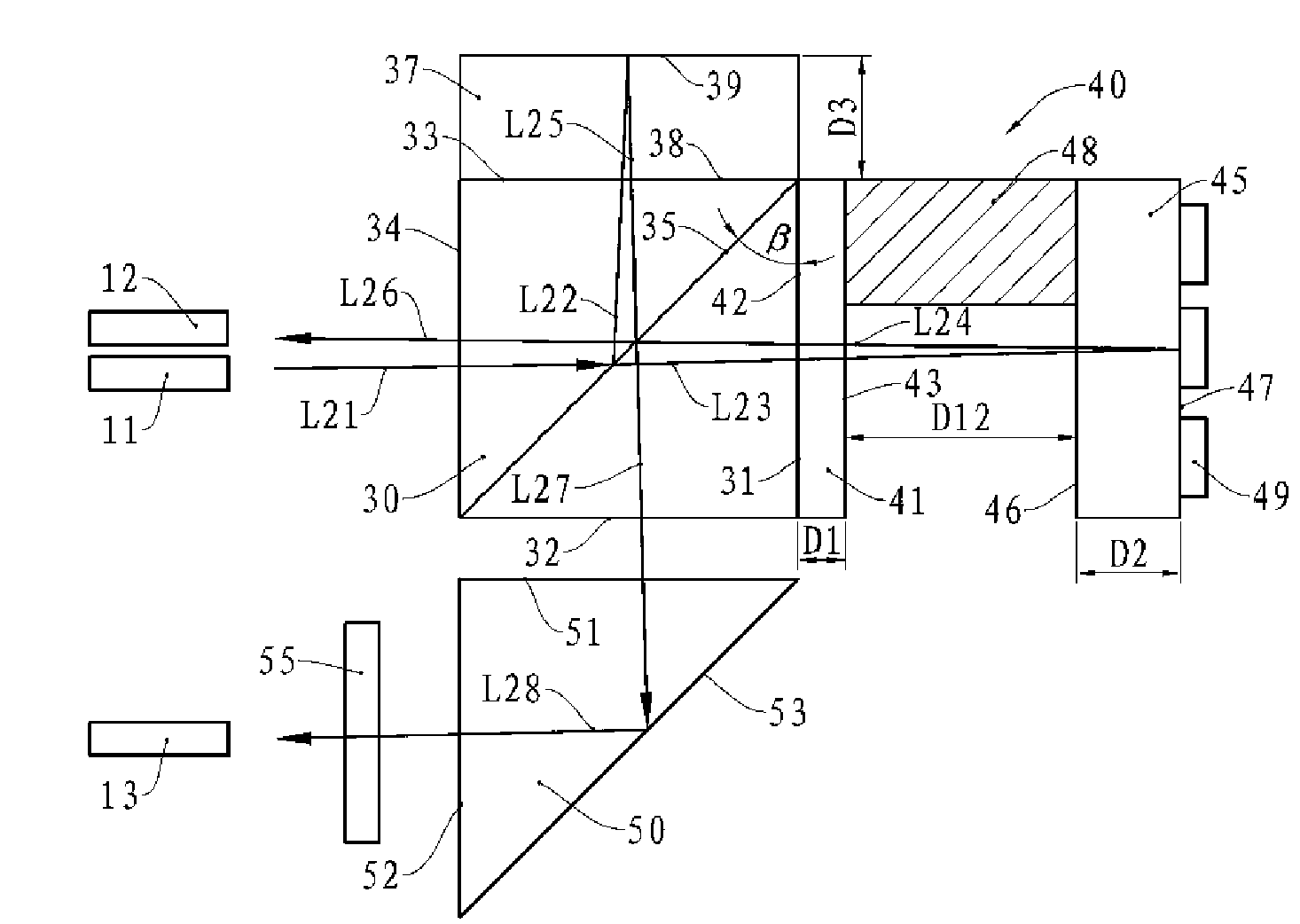

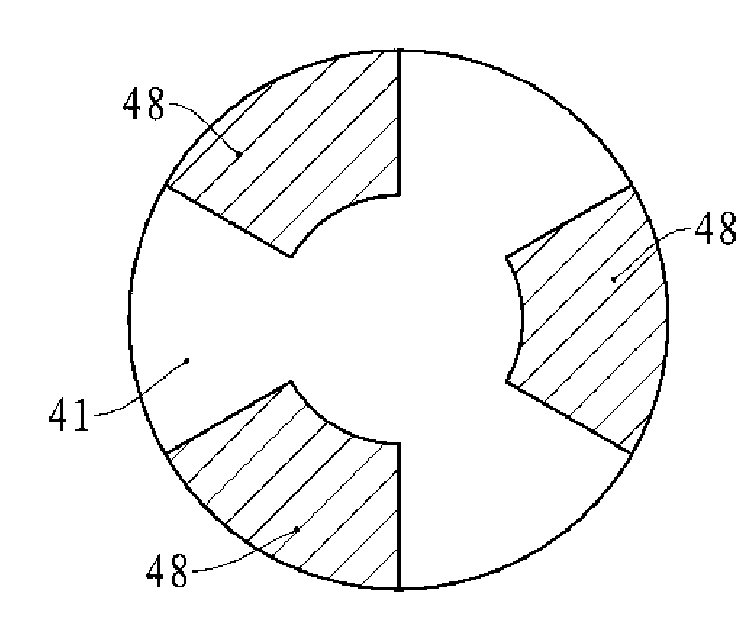

[0028] see figure 2 , this embodiment has an input port 11, a first output port 12, and a second output port 13, and the three ports are arranged on the same side. The present embodiment is also provided with a beam splitter 30, the cross section of the beam splitter 30 is rectangular, one of its diagonals forms a beam splitting surface 35, the beam splitting surface 35 is a 50:50 beam splitting film, and the light beam incident on the beam splitting surface 35 is as follows The ratio forms the transmitted beam and the reflected beam.

[0029] One end surface of the beam splitter 30 is the first light-transmitting surface 31 , and the angle β formed between the first light-transmitting surface 31 and the light-splitting surface 35 is 45°. An end surface perpendicular to the first light-transmitting surface 31 is the second light-transmitting surface 32, the end surface opposite to the second light-transmitting surface 32 is the third light-transmitting surface 33, and the en...

no. 2 example

[0050] Same as the first embodiment, this embodiment has one input port and two output ports, and is provided with a beam splitter, and the beam splitter is provided with a light splitting surface and four light-transmitting surfaces, and outside the first light-transmitting surface is provided For the interference arm etalon, a reflective prism and a phase retardation film are arranged outside the second light-transmitting surface, and a compensation film is arranged outside the third light-transmitting surface, which will not be repeated here.

[0051] see Figure 4 , the interference arm etalon 60 of the present embodiment has a first optical glass 61 and a second optical glass 62, and a partition made of a material insensitive to temperature change is arranged between the first optical glass 61 and the second optical glass 62 68. The partition 68 in this embodiment is an annular body, which is continuously distributed in the circumferential direction between the first opt...

no. 3 example

[0054] Same as the first embodiment, this embodiment also has an input port and two output ports, and is provided with a beam splitter, an interference arm etalon, a compensation sheet, and a reflection prism, etc. The structure of the interference arm etalon of this embodiment is as follows Figure 5 shown.

[0055] The interference arm etalon 70 has a first optical glass 71 and a second optical glass 75, the cross section of the first optical glass 71 is wedge-shaped, and it has an outer surface 72 and an inner surface 73, the outer surface 71 and the first light transmission of the beam splitter Face to face, the plane where the inner surface 73 is located intersects the plane where the outer surface 71 is located, that is, the plane where the inner surface 73 is located intersects the plane where the first light-transmitting surface of the beam splitter is located.

[0056] The second optical glass 75 also has an outer surface 77 and an inner surface 76 , the inner surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com