High and low pressure combined reactive compensation control system for submerged arc furnace

A compensation control, submerged arc furnace technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve problems such as furnace condition deterioration, electrode current reduction, furnace life reduction, etc., to achieve comprehensive information and parameters Complete, guaranteed effectiveness of data and information sharing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

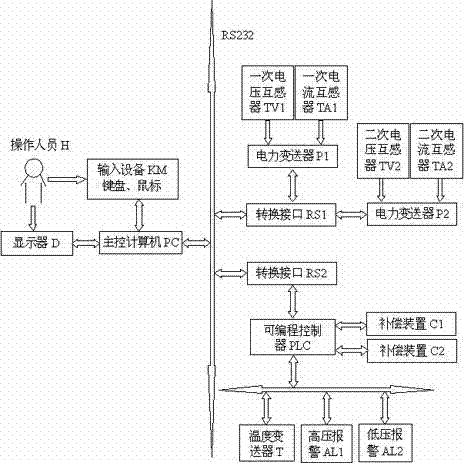

[0056] Submerged arc furnace high and low pressure combined reactive power compensation control system such as figure 1 As shown, it includes the primary side voltage transformer TV1, the primary side current transformer TA1, the secondary side voltage transformer TV2, and the secondary side current transformer TA2 for data collection from the primary high voltage side and secondary low voltage side of the submerged arc furnace transformer. , the primary side voltage transformer TV1 and the primary side current transformer TA1 are respectively connected to the input port of the power transmitter P1, and the secondary side voltage transformer TV2 and the secondary side current transformer TA2 are respectively connected to the input port of the power transmitter P2 , the power transmitter P1 and the power transmitter P2 are electrically connected to the main control computer through the interface, and provide the current and voltage data of the primary high-voltage side and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com