Redundant hardware architecture for the control signal stage of a braking system for a vehicle all the wheels of which are each connected to at least one rotary electrical machine

A technology of rotating motors and control signals, which is applied in the field of road vehicle systems and can solve problems such as electric brakes that are not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

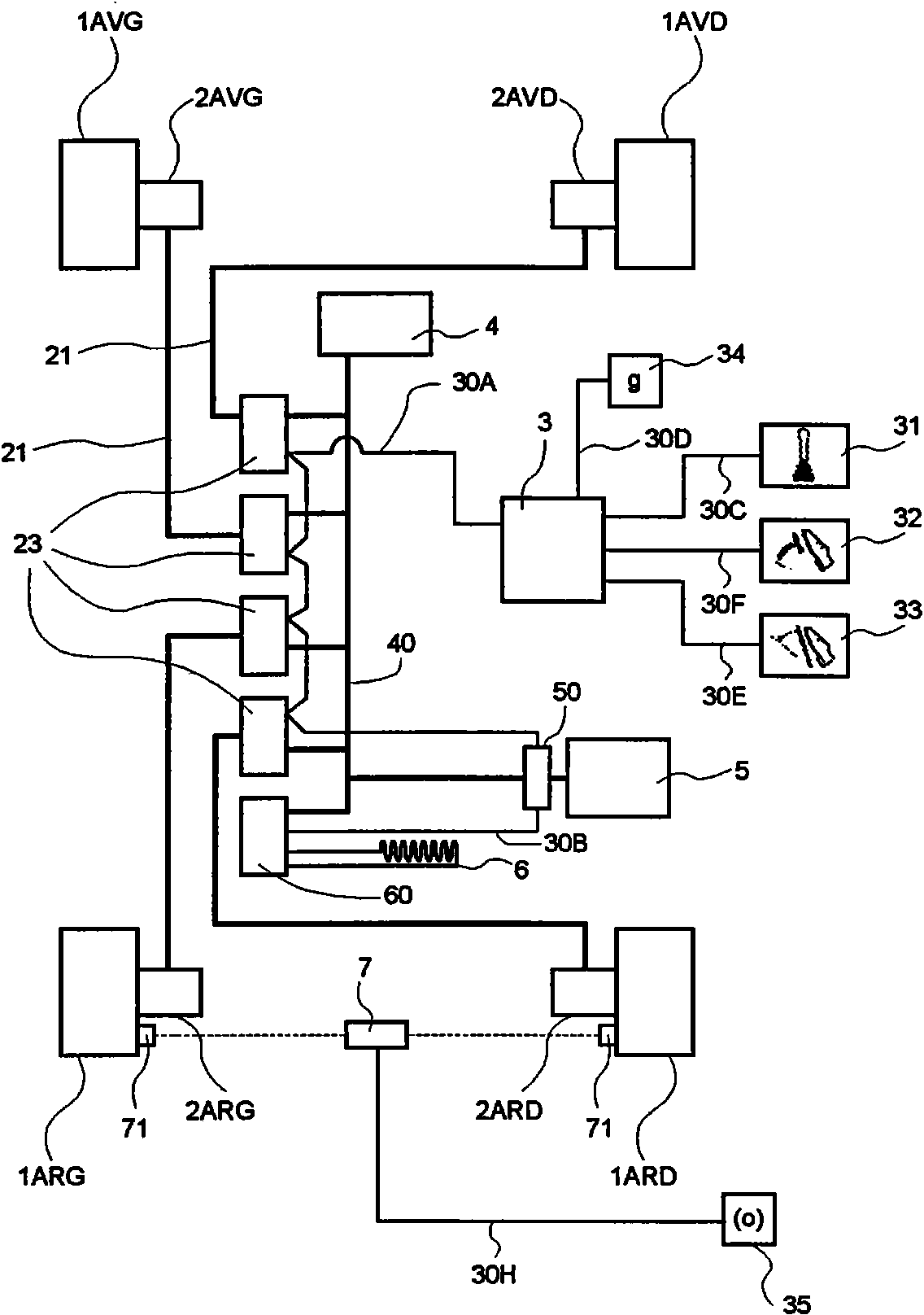

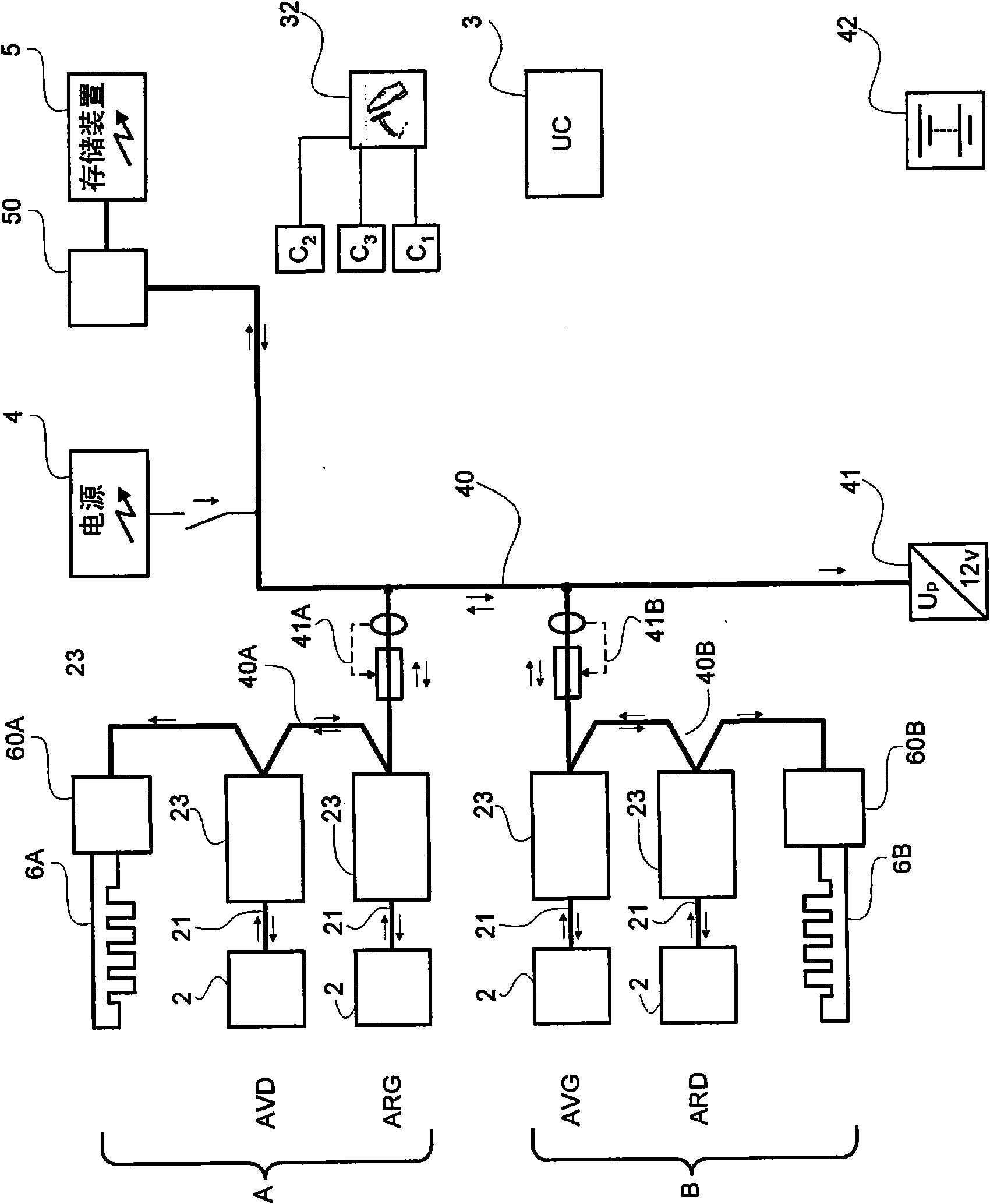

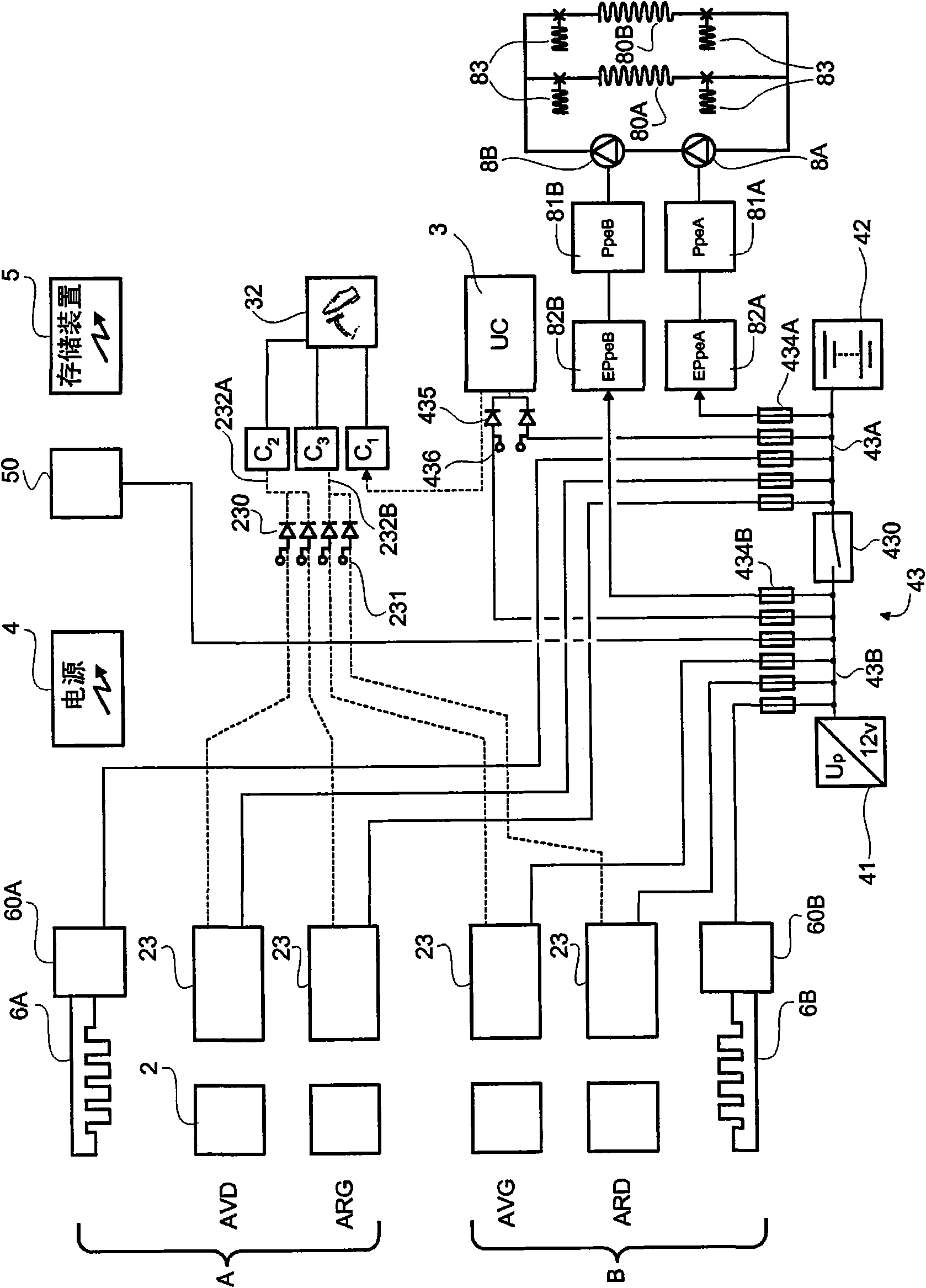

[0031] figure 1 is schematically shown with four wheels 1 AvG ,1 AvD ,1 ArG and 1 ArD Vehicles. Wheels are labeled 1 AvG Indicates the left front wheel, 1 AvD Indicates the right front wheel, 1 ArG Indicates the left rear wheel, 1 ArD Indicates the right rear wheel. Each wheel is equipped with an electric motor mechanically coupled to it. Motor 2 AvG ,2 AvD ,2 ArG and 2 ArD is shown. In the following, subscripts specifically indicating the positions of the wheels 1 or the motor 2 in the vehicle are not repeated when they have no effect on the clarity of the description in this specification. The electric traction machine 2 is a three-phase synchronous motor equipped with resolver-type angular position sensors and driven by wheel drive electronics modules 23 to which they are connected via power supply lines 21 . The wheel drive electronics module 23 is designed to be able to drive the electric motor in terms of torque. Each wheel drive electronics module 23 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com