Waste collection facility with storage tank and service space

A technology for collecting equipment and overhauling space, which is applied in the field of waste collection equipment and can solve problems such as water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

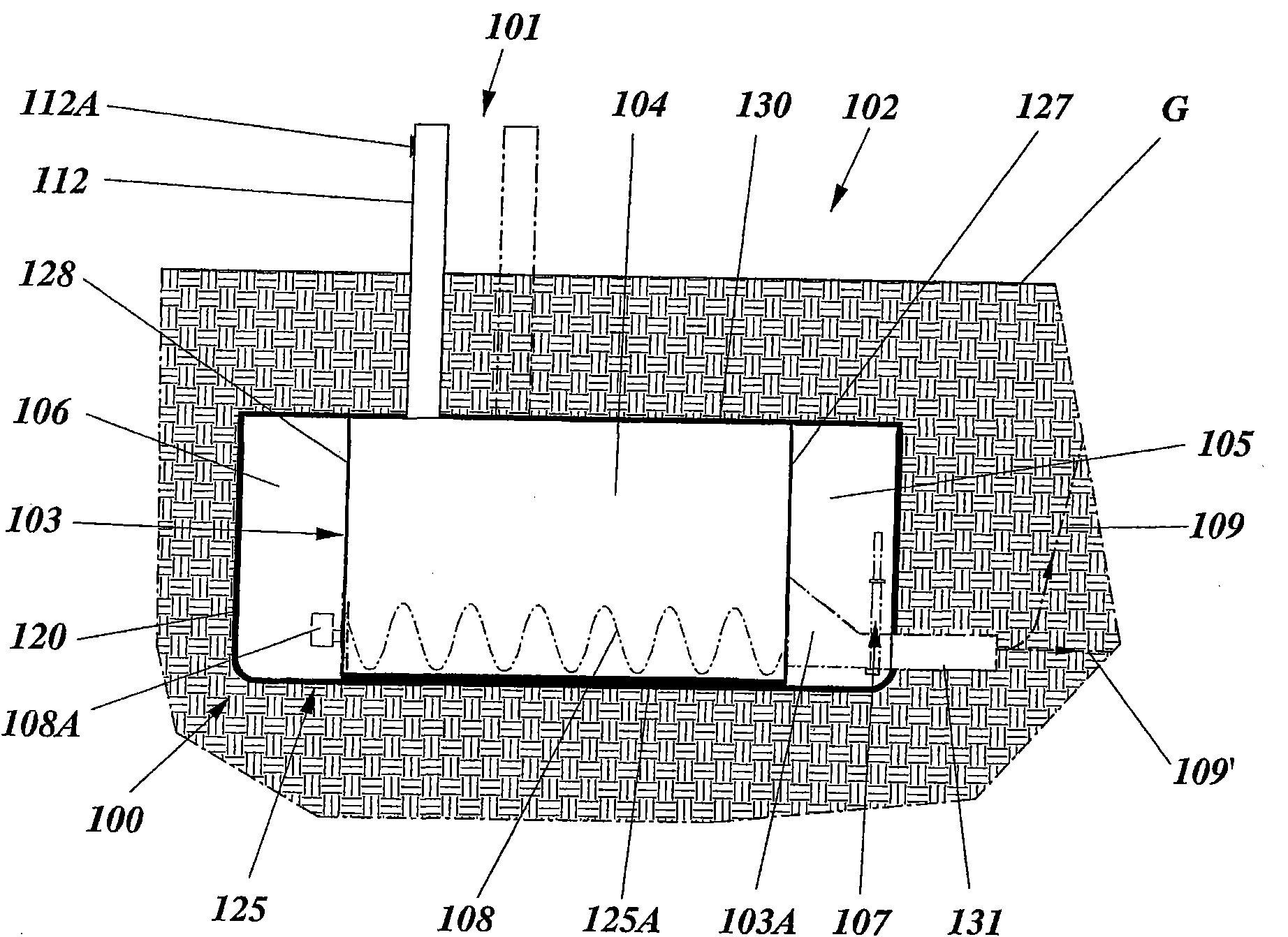

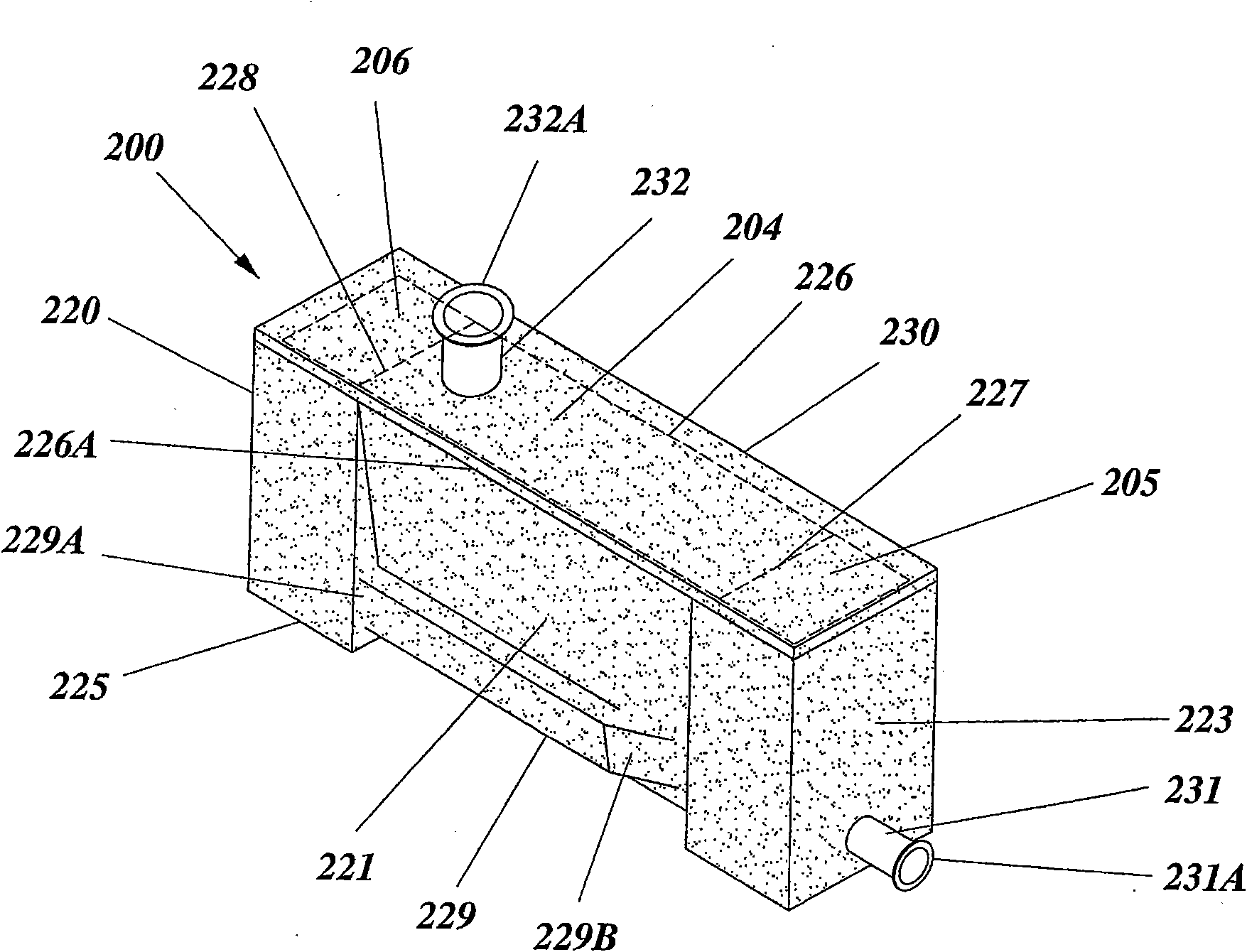

[0024] Reference will now be made to an illustrative embodiment of the waste collection apparatus of the present invention, described with reference to the accompanying Figure 2-6 Make a diagram. The illustrative embodiment shown in the figures relates to the application of the invention to a waste collection system comprising an underground temporary waste storage tank having a screw-shaped agitator device. It should be emphasized that the illustration is for the purpose of describing a preferred embodiment of the invention and is not intended to limit the invention to its details.

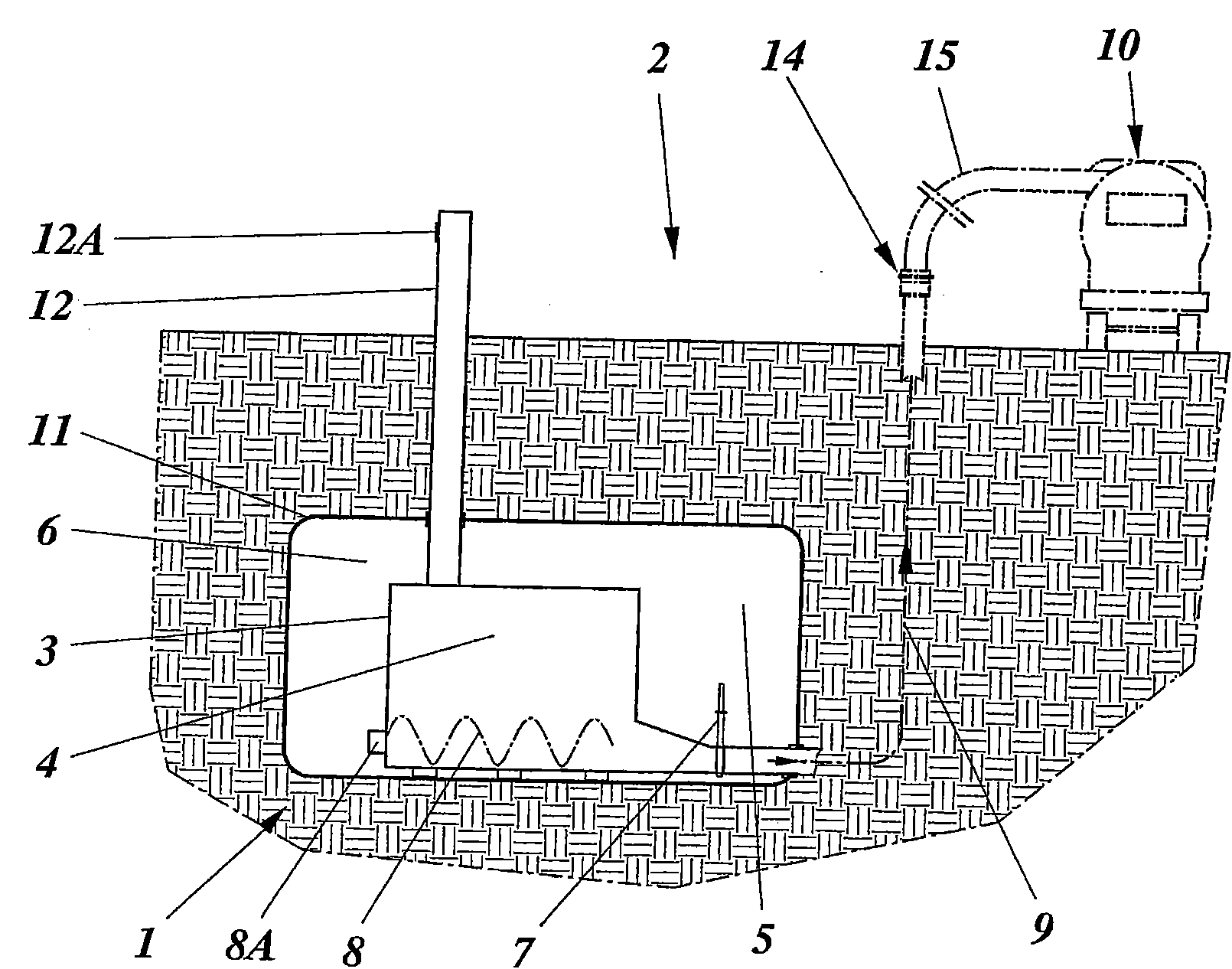

[0025] figure 1 A partial schematic diagram of an example of a conventional vacuum waste collection system 2 is shown, together with the waste collection point 1 in use as described above. Specifically, figure 1 A mobile vacuum operated waste collection system 2 with an underground temporary storage tank 3 is shown. In this system, the waste is deposited by opening the waste inlet 12A provid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap