A method of managing waste and a system for collecting waste

A technology of waste treatment and collection system, applied in the direction of solid waste removal, garbage collection, chemical instruments and methods, etc., can solve problems such as injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

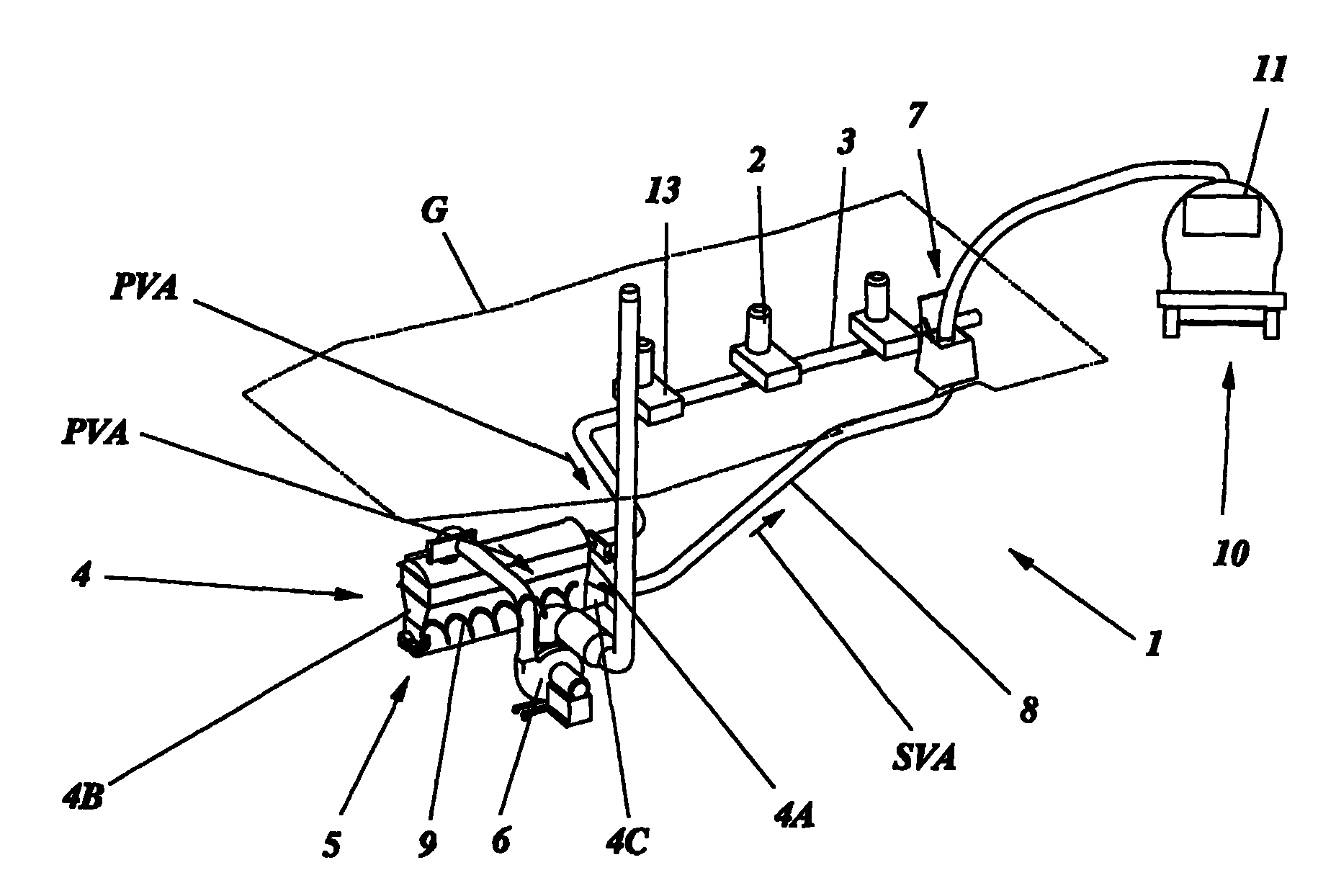

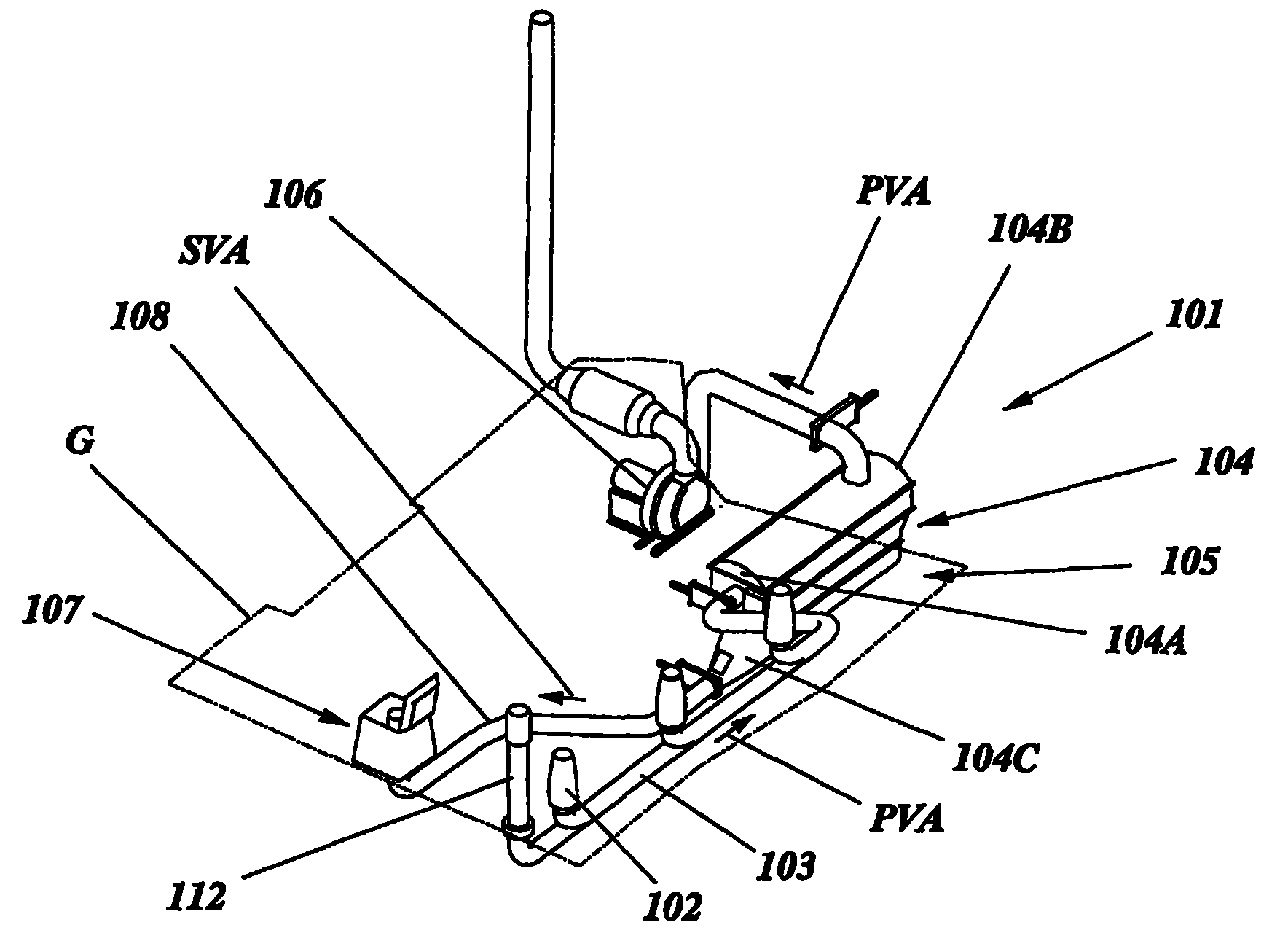

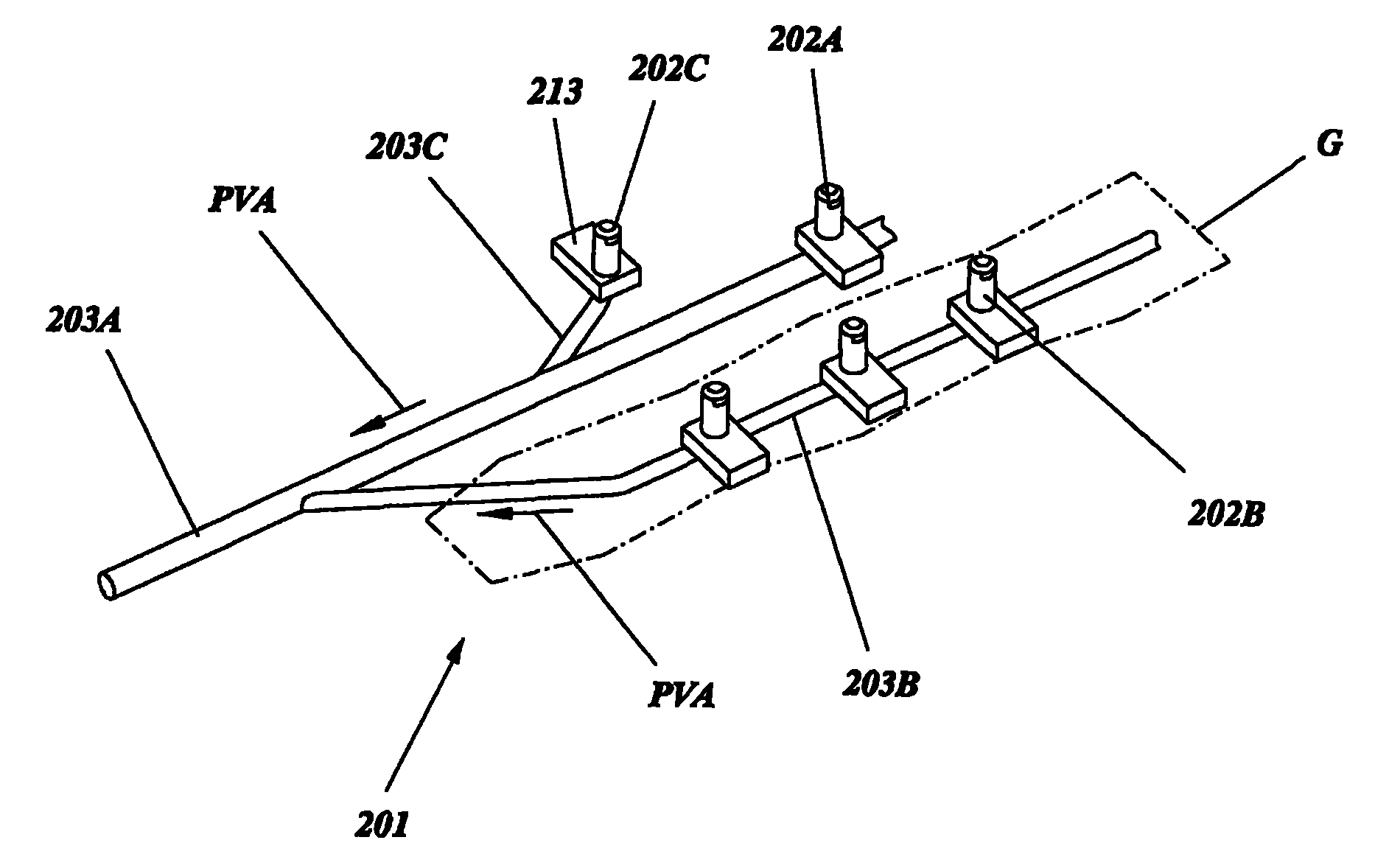

[0020] The invention will now be explained on the basis of an exemplary embodiment of the waste collection system of the invention, which is shown in the accompanying drawings. An example application of the invention is in Figure 1-5 shown in , and relates to the application of the invention to a partially and very exemplary generalized stationary vacuum waste collection system. It is emphasized that the preferred embodiments of the invention have been described for purposes of explanation, and no attempt is made to limit the invention to the details described.

[0021] As mainly discussed above, a conventional stationary vacuum waste collection system can achieve an excellent waste disposal solution due to the powerful suction provided by the stationary vacuum source. The system is capable of conveying the collected waste over considerable distances from storage points, such as so-called waste bins, distributed over a wide area. A high waste transfer capacity in heavy duty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com