Hot-dip coating installation

A hot-dip plating and equipment technology, applied in hot-dip plating process, mechanical equipment, coating and other directions, can solve problems such as damage to the surface of the strip, and achieve the effect of eliminating the possibility of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, the present invention will be described in detail in the form of embodiments with reference to the accompanying drawings.

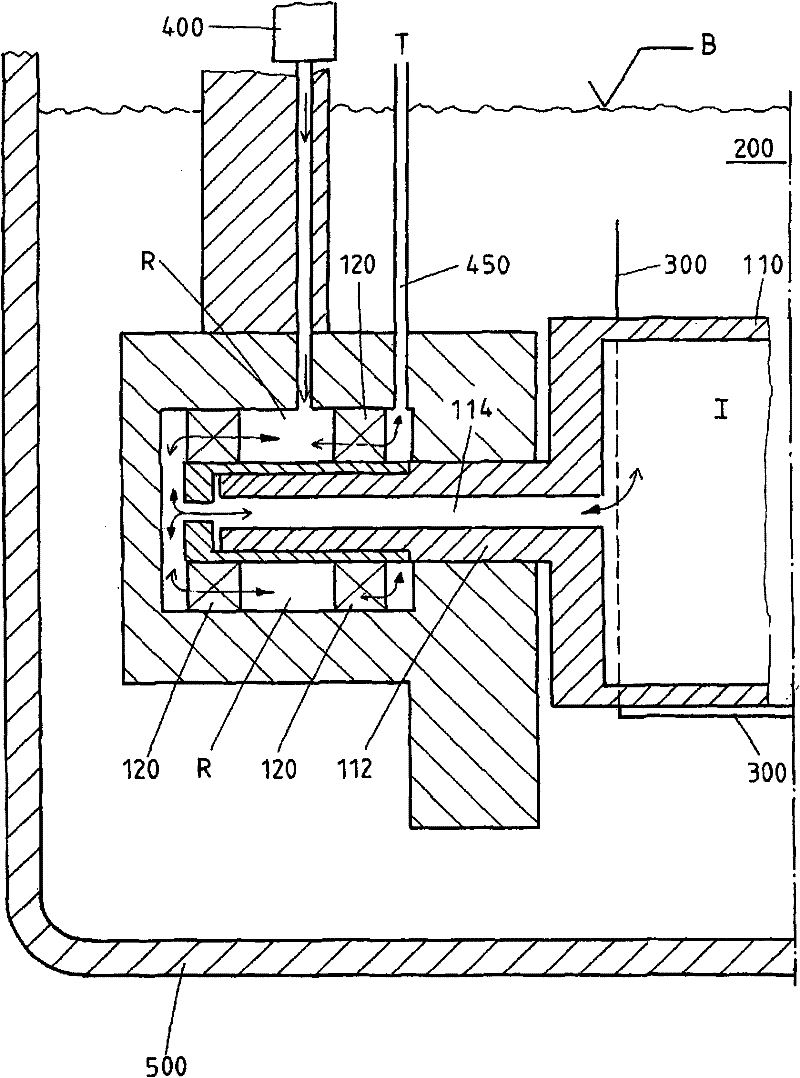

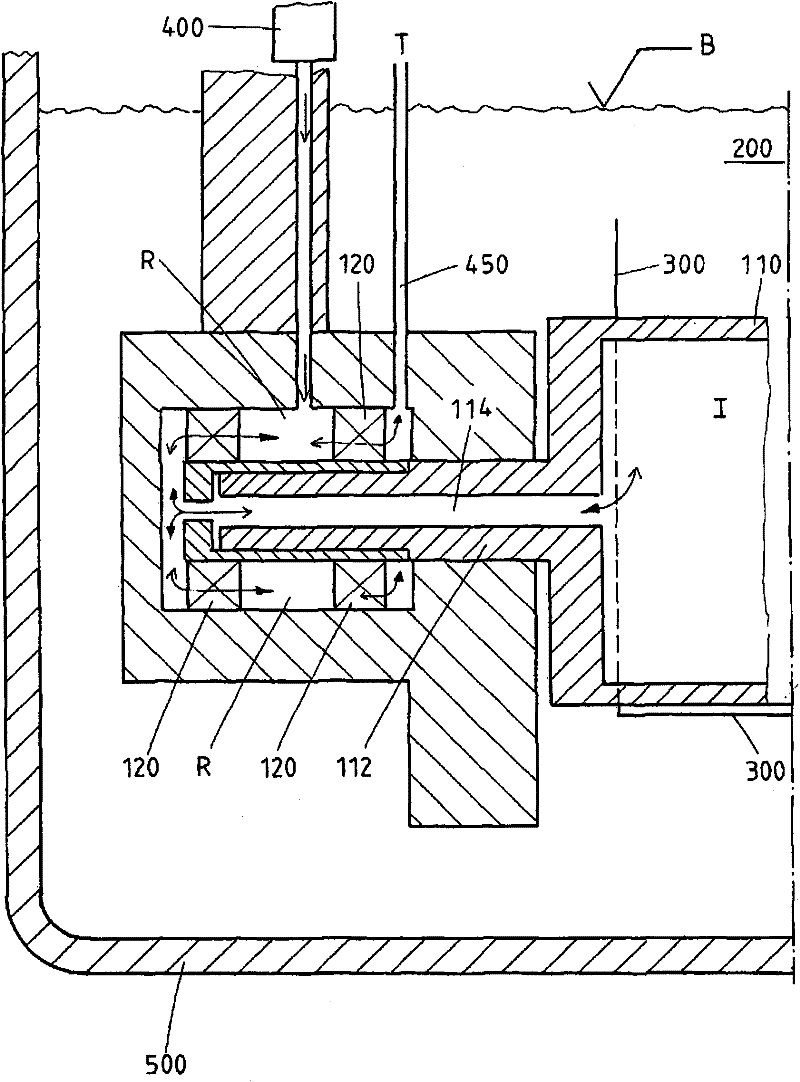

[0015] The drawing shows a cross-section through a hot-dip coating installation for coating a strip 300 , in particular steel strip, with a molten metal 200 . The hot-dip galvanizing plant comprises a vessel 500 containing molten metal in which a roll 110 supported on a support arm is immersed. Roller 110 is shown in the drawing, for example, in the form of a deflection roll for deflecting the strip in molten metal 200 . The roll 110 is in the form of a hollow body with an inner cavity I and is sealed against the surrounding molten metal 200 . The roll 110 has a roll neck 112, by means of which the roll is mounted in a bearing 120, preferably a roller bearing. The bearing 120 is arranged on the roll neck circumference and is surrounded by a space region R. As shown in FIG. According to the invention, the interior I of the roller 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com