Grinding device for cutter slot

A groove and grinding technology, used in grinding/polishing equipment, grinding machines, manufacturing tools, etc., can solve the problems of low tool groove grinding efficiency, inability to process tool angles, and inability to realize spindle rotation, etc. Easy and flexible spiral movement, wide grinding range and quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

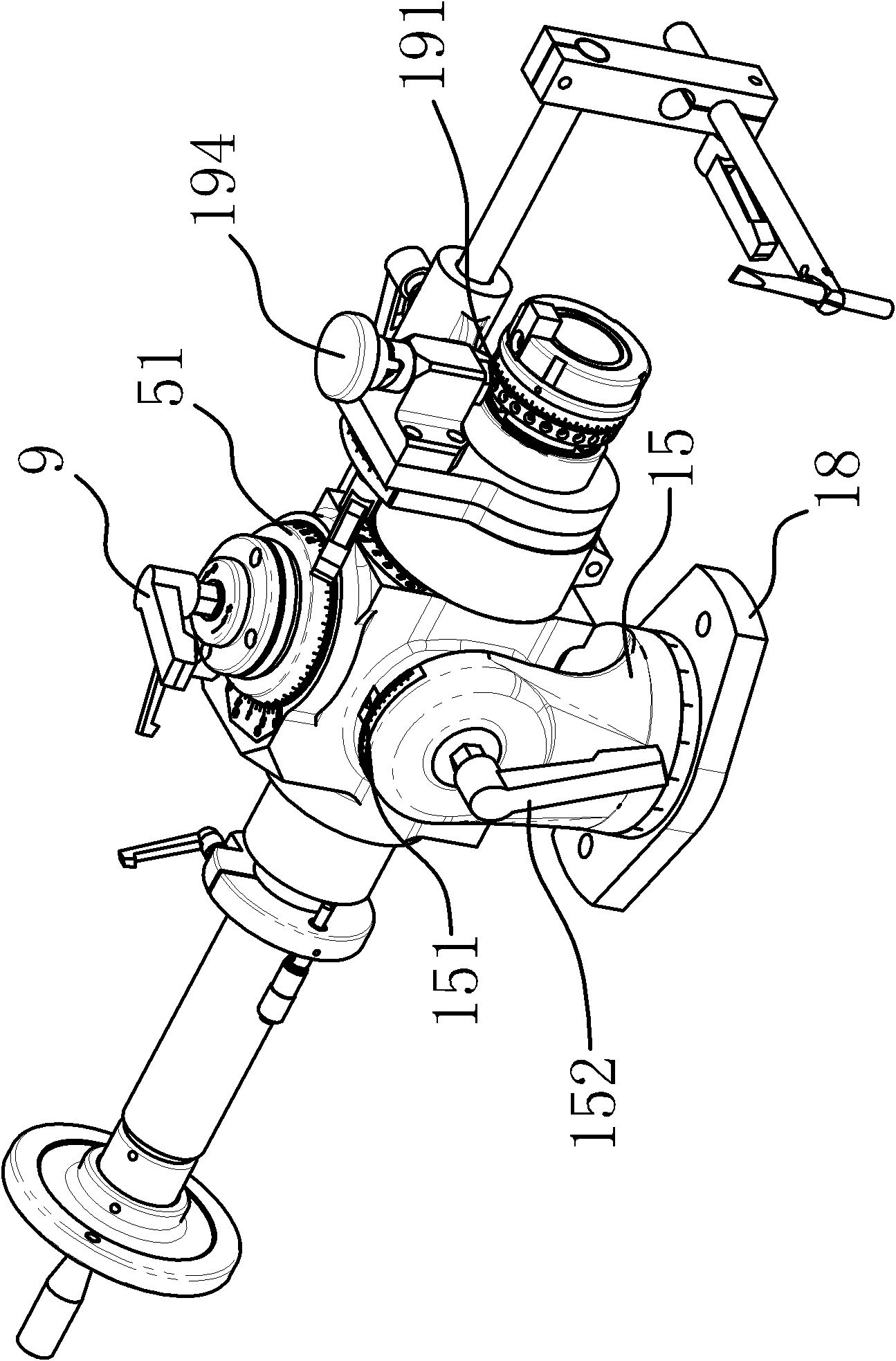

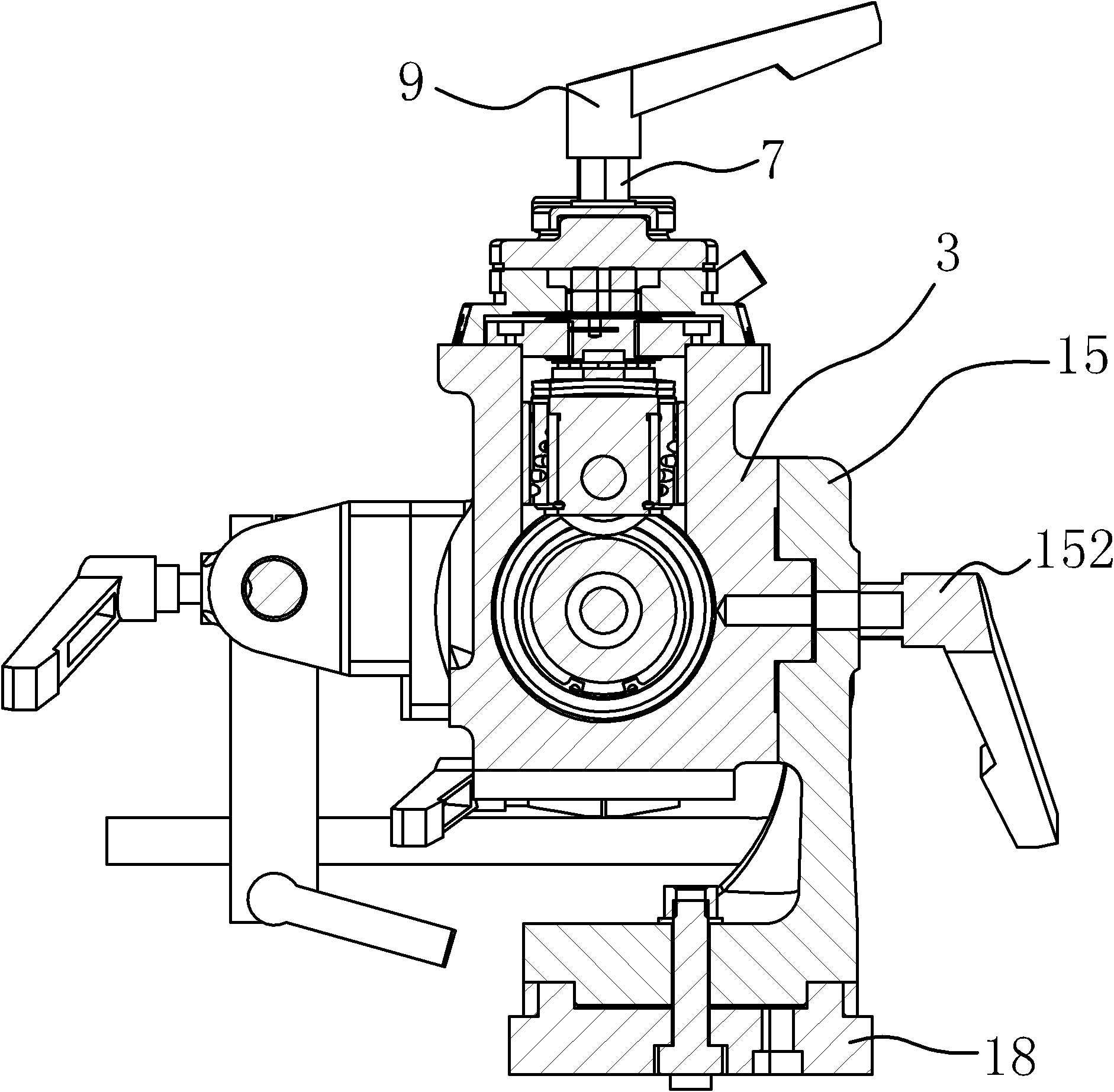

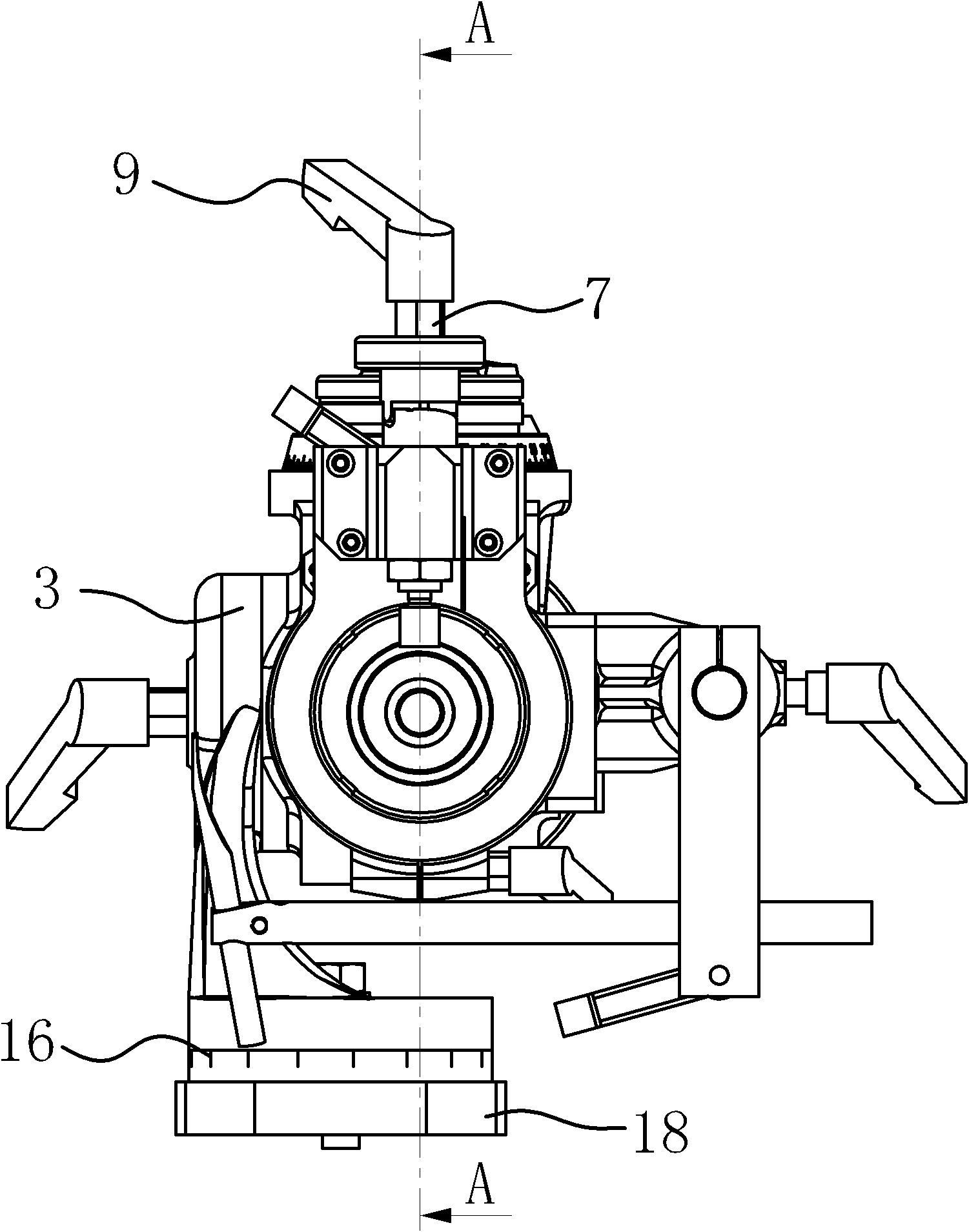

[0035] Such as figure 1 As shown, the grinding device of the cutter groove is made up of parts such as main shaft 1, pressure bar 2, support seat 3 and adjustment mechanism 5.

[0036] Specifically, as figure 1 , figure 2 and image 3 As shown, the grinding device for the tool groove is installed on the workbench of the grinding machine. The main shaft 1 is cylindrical and pierced on the supporting seat 3. The pressing rod 2 passes through the supporting seat 3 along the radial direction of the main shaft 1. The pressing bar 2 The end close to the main shaft 1 is fixedly connected with a pressure bearing 4 whose outer ring can be in contact with the outer surface of the main shaft 1, and the end of the pressure rod 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com