Motor-driven tipping device of slag pot car and working procedure thereof

A technology of tipping device and slag tanker, which is applied in the direction of dump truck, transport passenger car, transportation and packaging, etc. It can solve the problems of heavy maintenance workload, complex structure, large axial force of screw, etc., and achieve production cost and maintenance The effect of cost reduction, simplification of transmission mechanism and improvement of transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

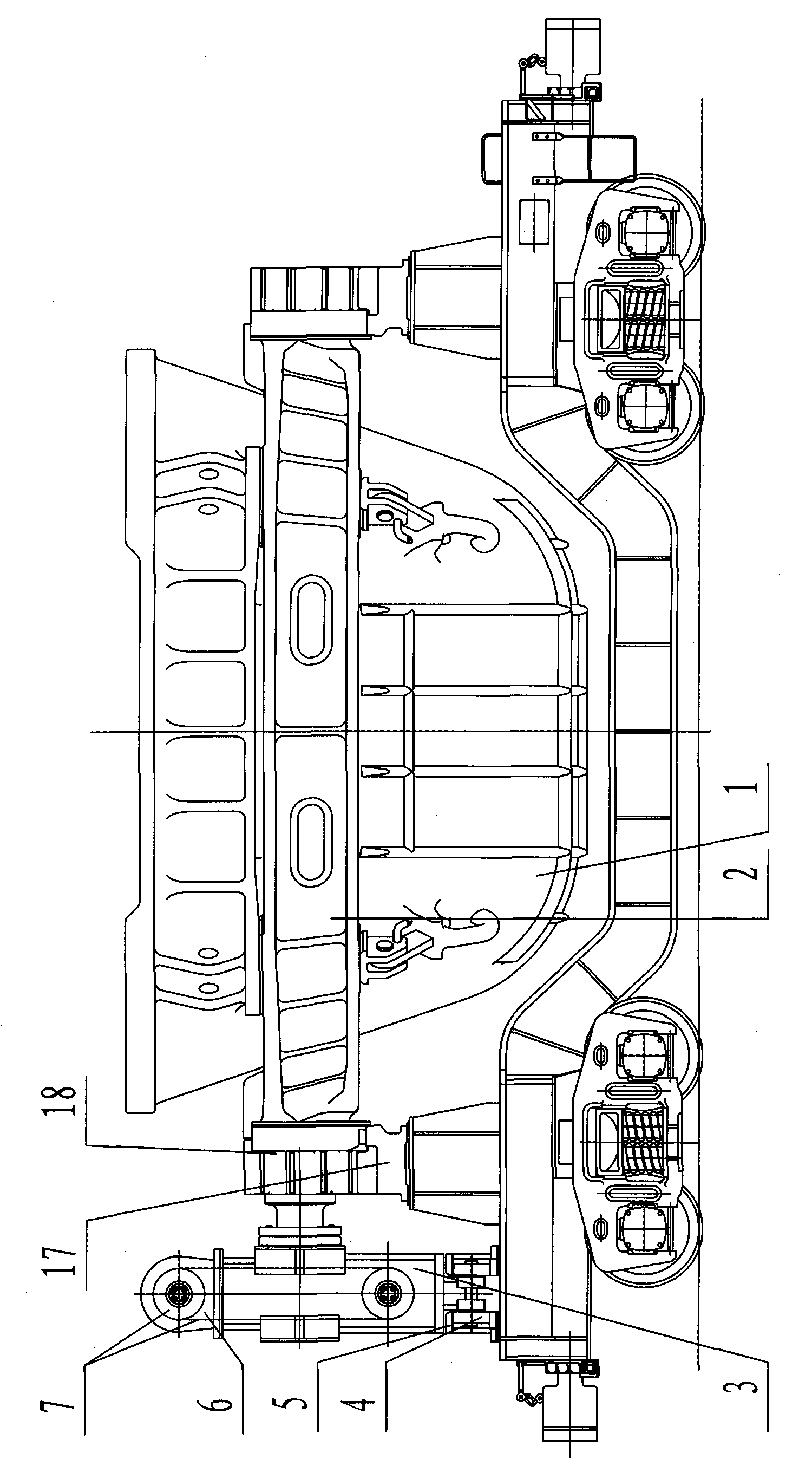

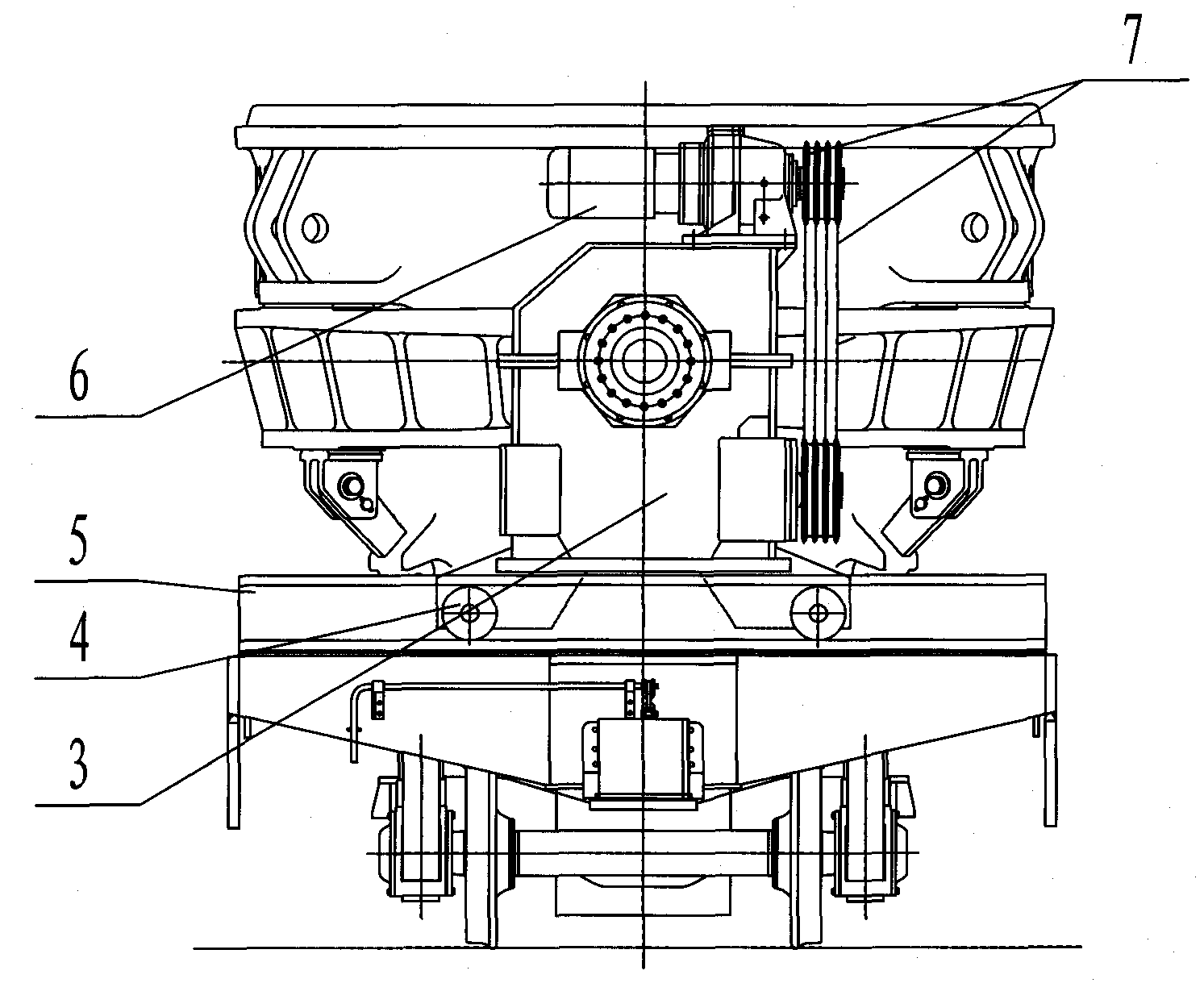

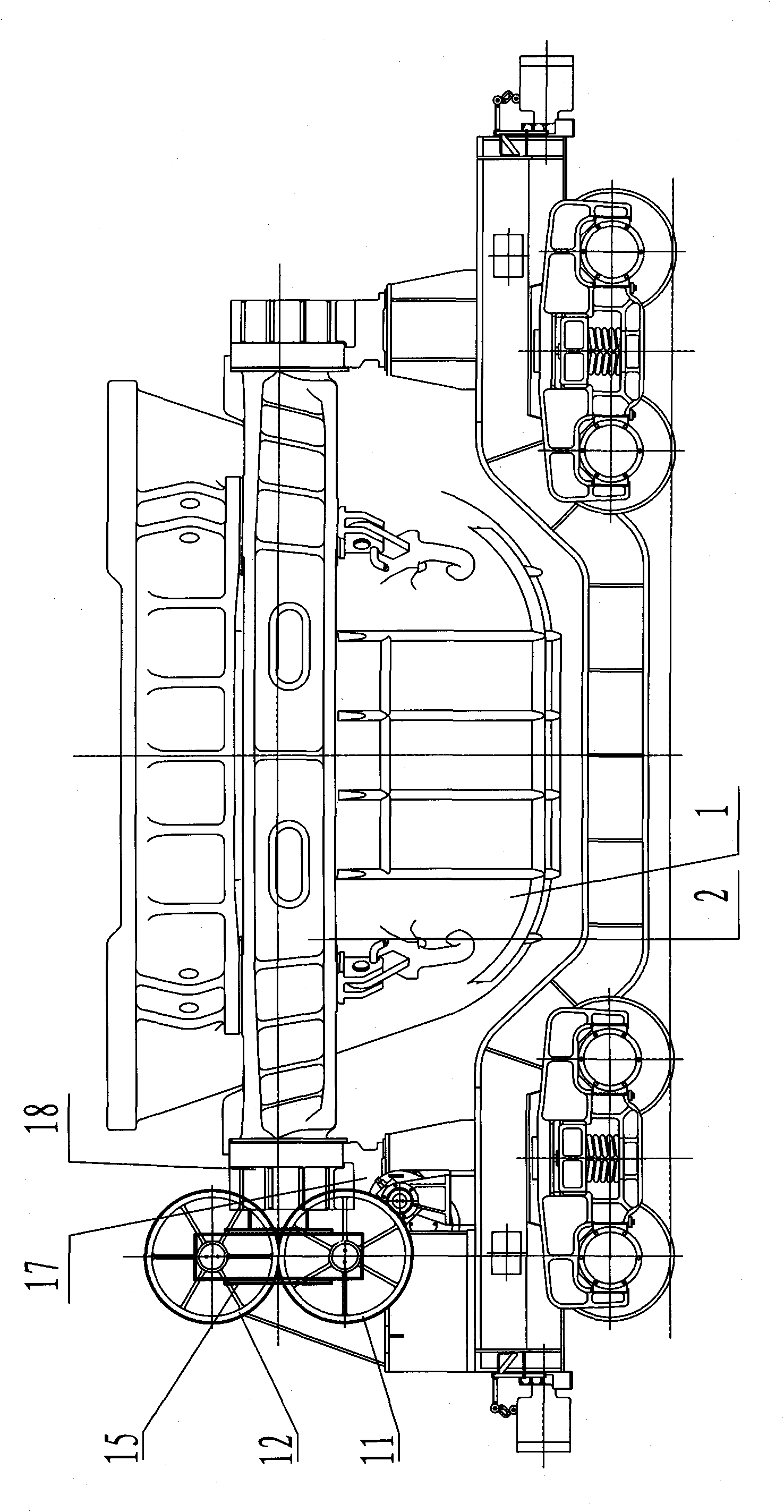

[0019] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-2 As shown, an electric tipping device for a slag tank car includes a worm gear reducer 3, a moment roller 4, a guide rail 5, a planetary cycloid reducer 6, and a chain sprocket device 7. The worm gear reducer 3 It has a self-locking function, and is connected to the trunnion of the slag tank support frame 2 through a locking disc, and is suspended on the trunnion. The upper part of the worm gear reducer 3 is equipped with a planetary cycloid reducer 6, and the chain sprocket device 7 is connected to the trunnion. The worm connection of the worm gear reducer 3, the planetary cycloid reducer 6 is equipped with a motor, and the torque roller 4 has two groups, which are respectively fixed on the lower part of the worm gear reducer 3 and located on the guide rail 5 Inside, its state is: when the electric tilting device is stationary, the torque roller 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com