Method for predicting extraction productivity of underground coal-seam gas

A production capacity prediction and coalbed methane technology, which is applied in mining equipment, earthwork drilling, gas discharge, etc., can solve problems such as production capacity prediction of drilling groups that cannot be extracted, and models that cannot meet actual production conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

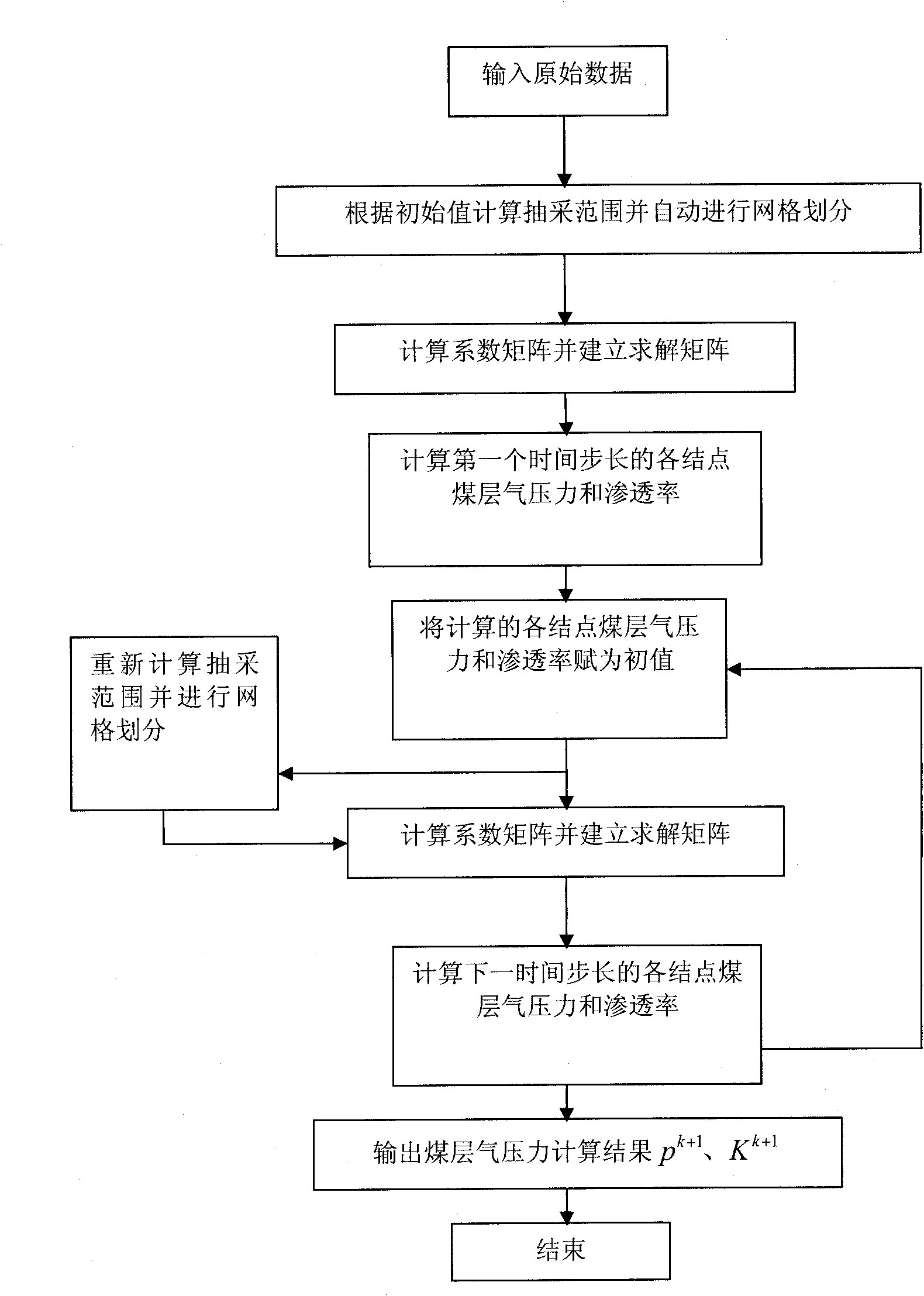

Method used

Image

Examples

Embodiment Construction

[0061] Preferred embodiments of the present invention will be described in detail below.

[0062] The main factors affecting the change of permeability in the process of coalbed methane drainage are effective stress and shrinkage effect of coal matrix. But the impact of the two on the permeability of the coal seam is just opposite, one is positive and the other is negative. Therefore, how to measure the comprehensive effect of the two factors on the coal seam permeability has become a problem that must be solved.

[0063] In the process of coalbed methane extraction, as the pressure of coalbed methane decreases, the effective stress increases, so that the permeability of the coal seam tends to decrease. At this time, the coal matrix shrinks, and the permeability of the coal seam tends to increase. The degree of influence of the two factors on the permeability of the coal seam can be expressed by the following two formulas:

[0064] ΔK 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com