Open type hot water tank

An open, heat storage technology, used in fluid heaters, lighting and heating equipment, etc., can solve the problems of slow temperature rise of hot water, high manufacturing and maintenance costs, slow temperature rise of manufactured hot water, etc. The effect of improving heat release efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

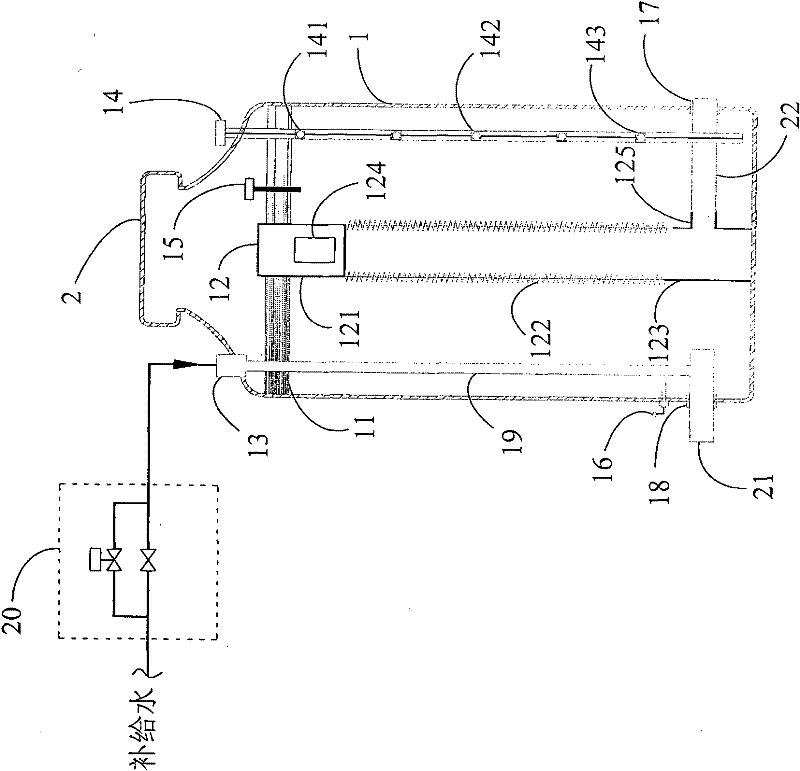

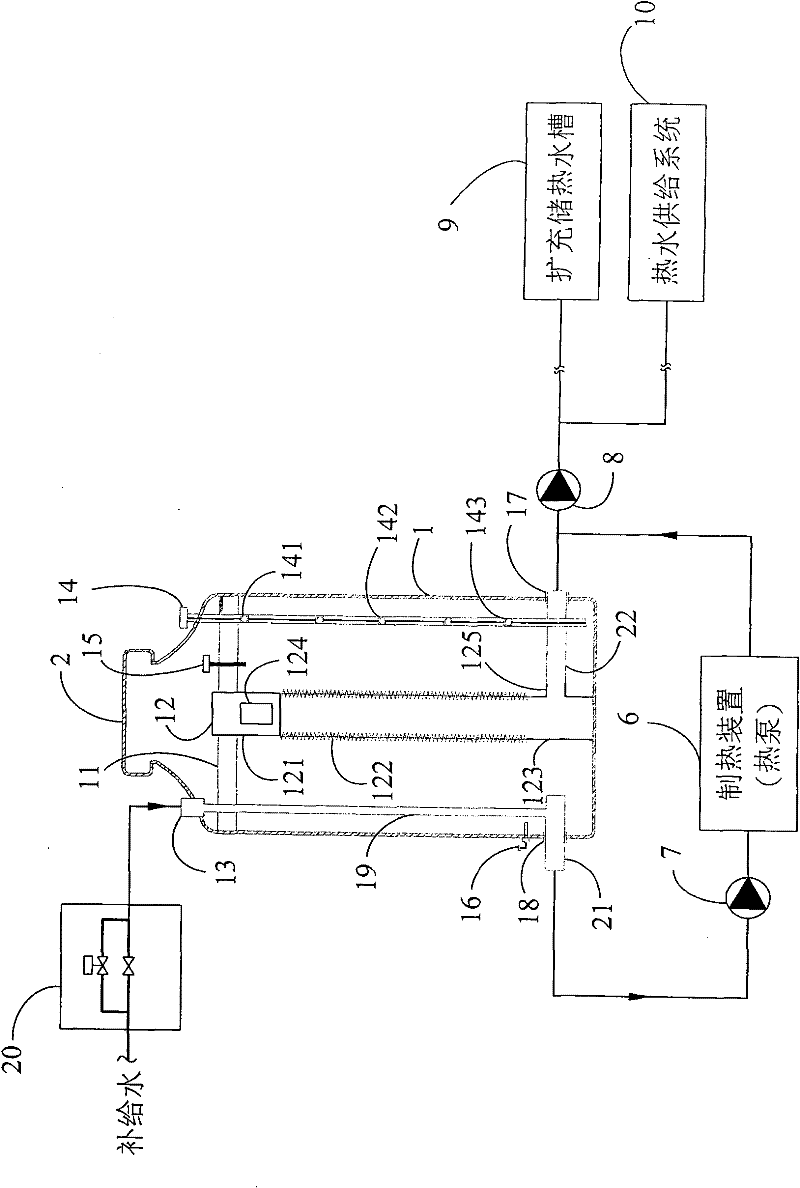

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

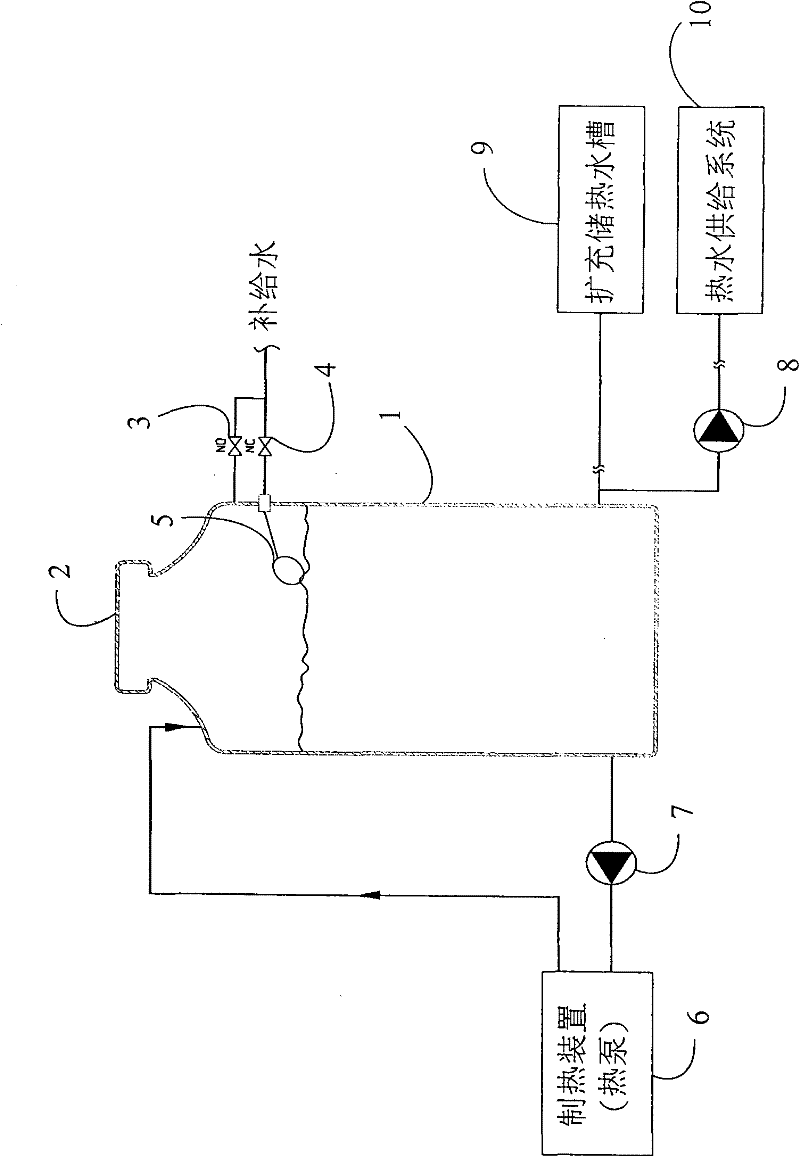

[0020] see figure 2 , is the system architecture diagram of the open hot water storage tank of the present invention. It can be seen from the figure that the system mainly includes:

[0021] Hot water storage tank 1;

[0022] The heat-insulating floating member 11 is arranged inside the hot water storage tank body 1, and the heat-insulating floating member 11 can not only move with the water surface, but also isolate the water surface from the air, so that the tank body 1 has a thermal stratification effect; In addition, a hot water supply temperature sensor 15 is arranged on the heat insulating floating part 11, and the temperature sensing part is in contact with the hot water and is close to the supply hot water inlet and outlet opening 124 of the flexible telescopic pipe fitting upper part 121 (near the heat insulating floating part 11 plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com