Method for producing flexible polyurethane foam, method for producing hot press molded article, and hot press molded article

A technology of soft polyurethane and manufacturing method, which is applied in the field of hot-pressed products to achieve the effects of excellent low resilience, excellent low resilience and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

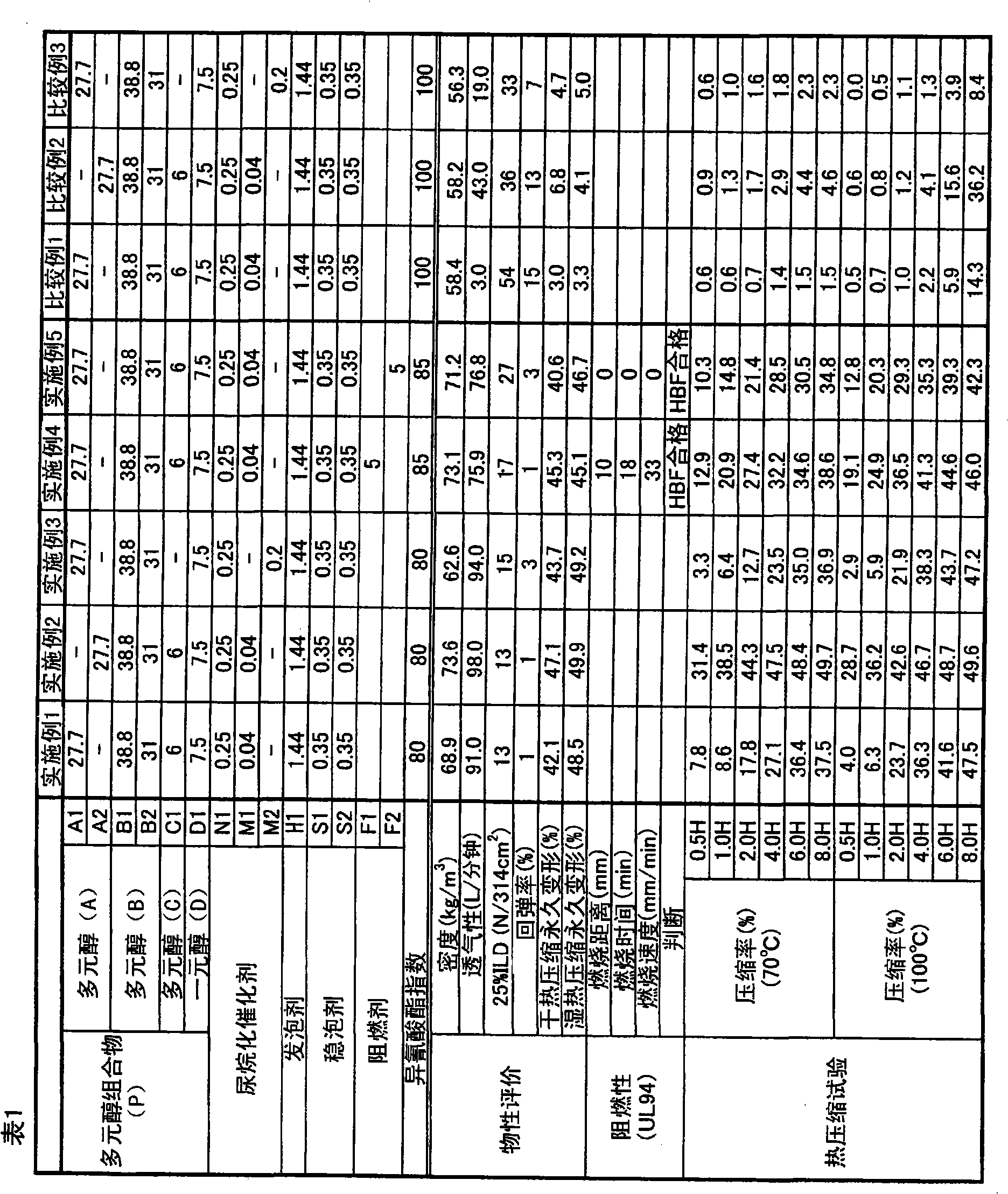

Embodiment 1

[0177] Polyol A1 (27.7 parts), polyol B1 (38.8 parts), polyol B2 (31 parts), polyol C1 (6 parts), monohydric alcohol D1 (7.5 parts), amine catalyst N1 (0.25 parts), metal Catalyst M1 (0.04 parts), water (1.44 parts), foam stabilizer S1 (0.35 parts) and foam stabilizer S2 (0.35 parts) were mixed to make a polyol system liquid, and adjusted to a liquid temperature of 21±1°C. In addition, polyisocyanate I1 (isocyanate index 80) was adjusted to a liquid temperature of 21±1°C.

[0178] Add a specified amount of the aforementioned polyisocyanate I1 (isocyanate index 80) to the aforementioned polyol system liquid, stir with a mixer (1425 revolutions per minute) for 5 seconds, and inject it into the open upper part of the length and width of 300 mm × height at room temperature In a 300mm wooden box, a vinyl film is laid in the wooden box to make a flexible foam (slab foam). The obtained flexible polyurethane foam was taken out, left to stand in a room adjusted to room temperature (23...

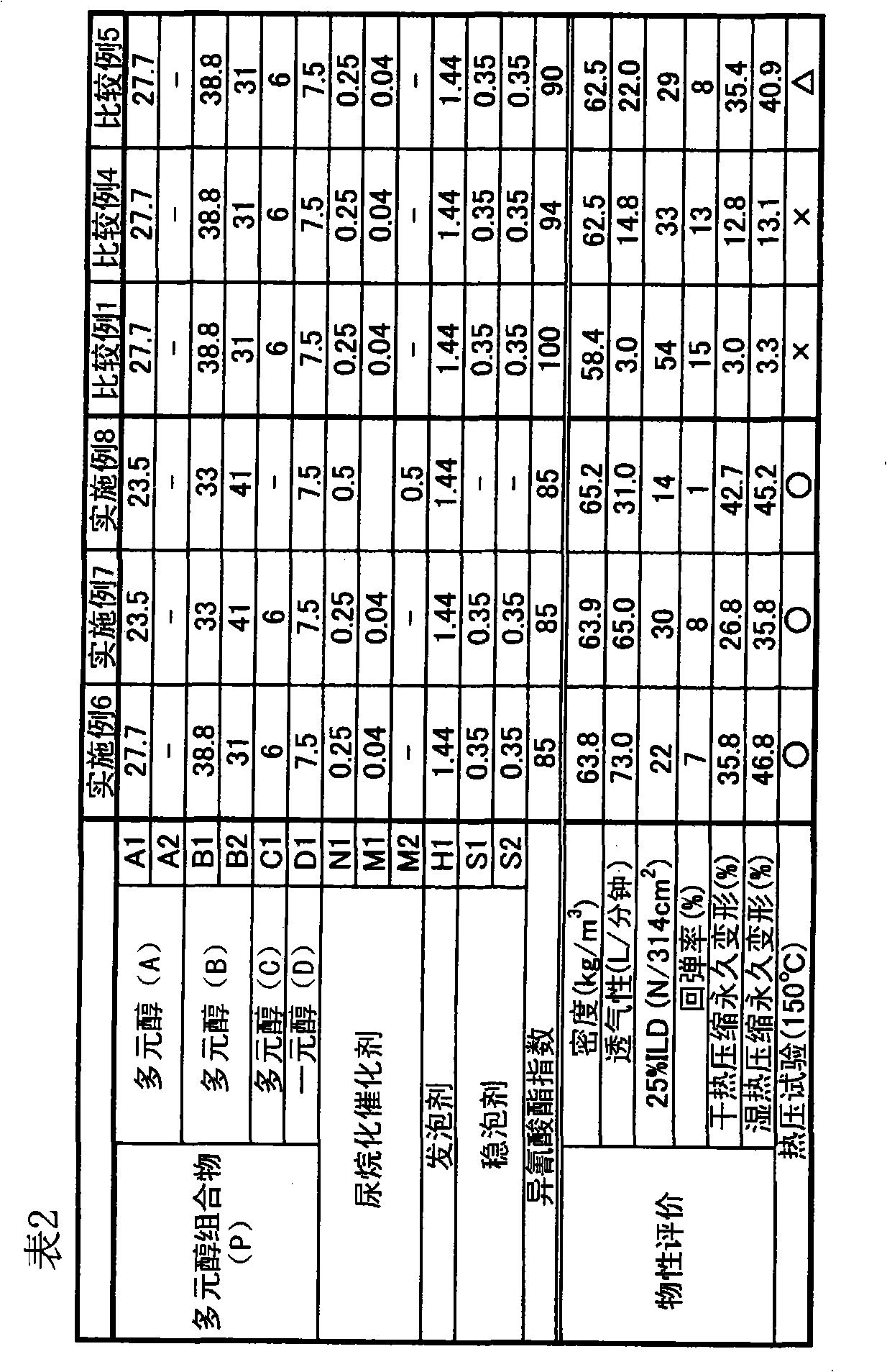

Embodiment 2~8

[0180] A flexible foam was obtained in the same manner as in Example 1 except that the composition and isocyanate index of the polyol system liquid were changed to those shown in Table 1 and Table 2, and various physical properties were measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com