Accumulator

A technology of accumulator and oil channel, which is applied in the direction of accumulator device, actuator accumulator, fluid pressure actuating device, etc., can solve the problem that the expansion and contraction stroke of the bellows cannot be ensured, and can prevent abnormal deformation and improve durability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0096] Embodiments of the present invention will be described below with reference to the drawings.

no. 1 example

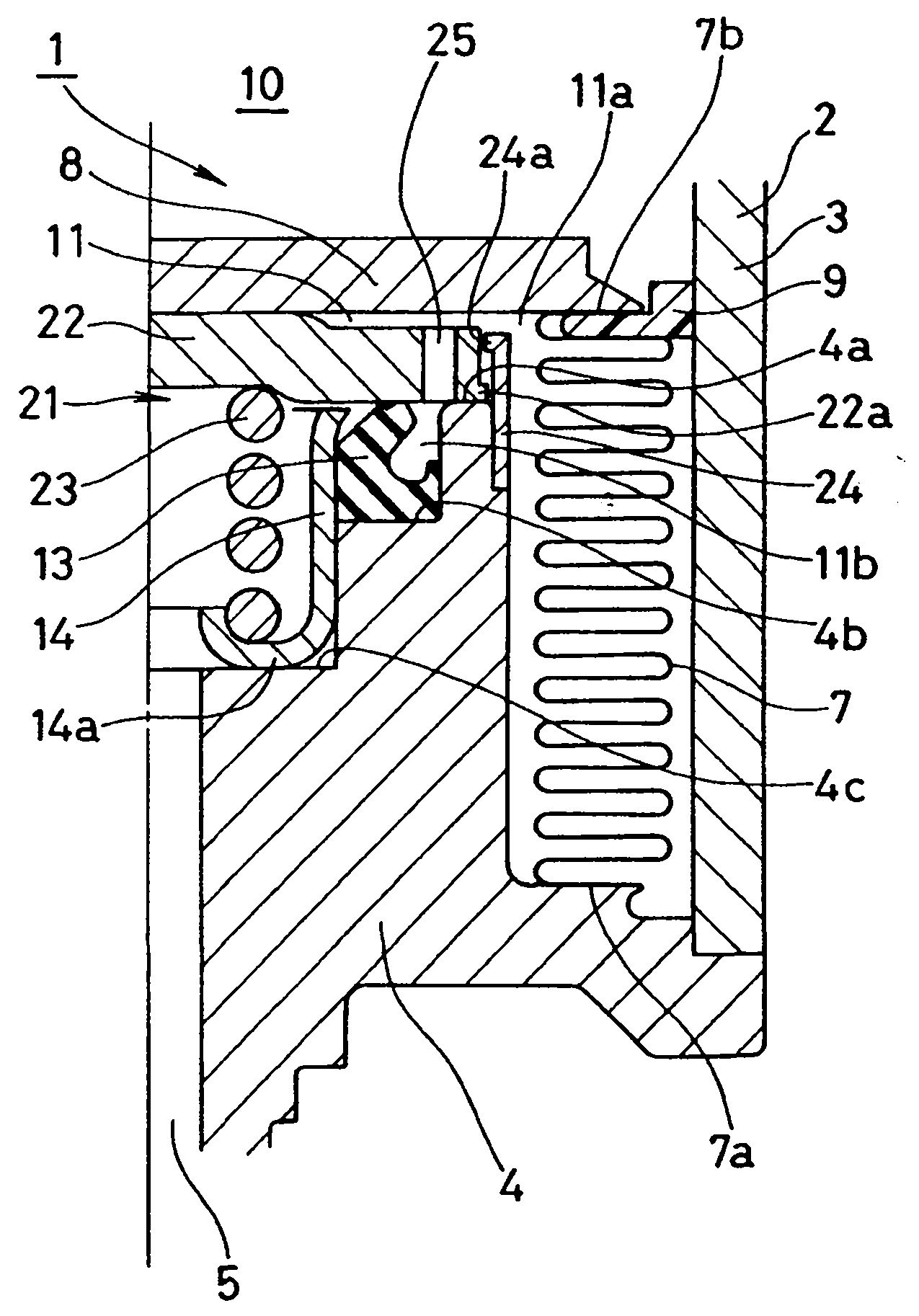

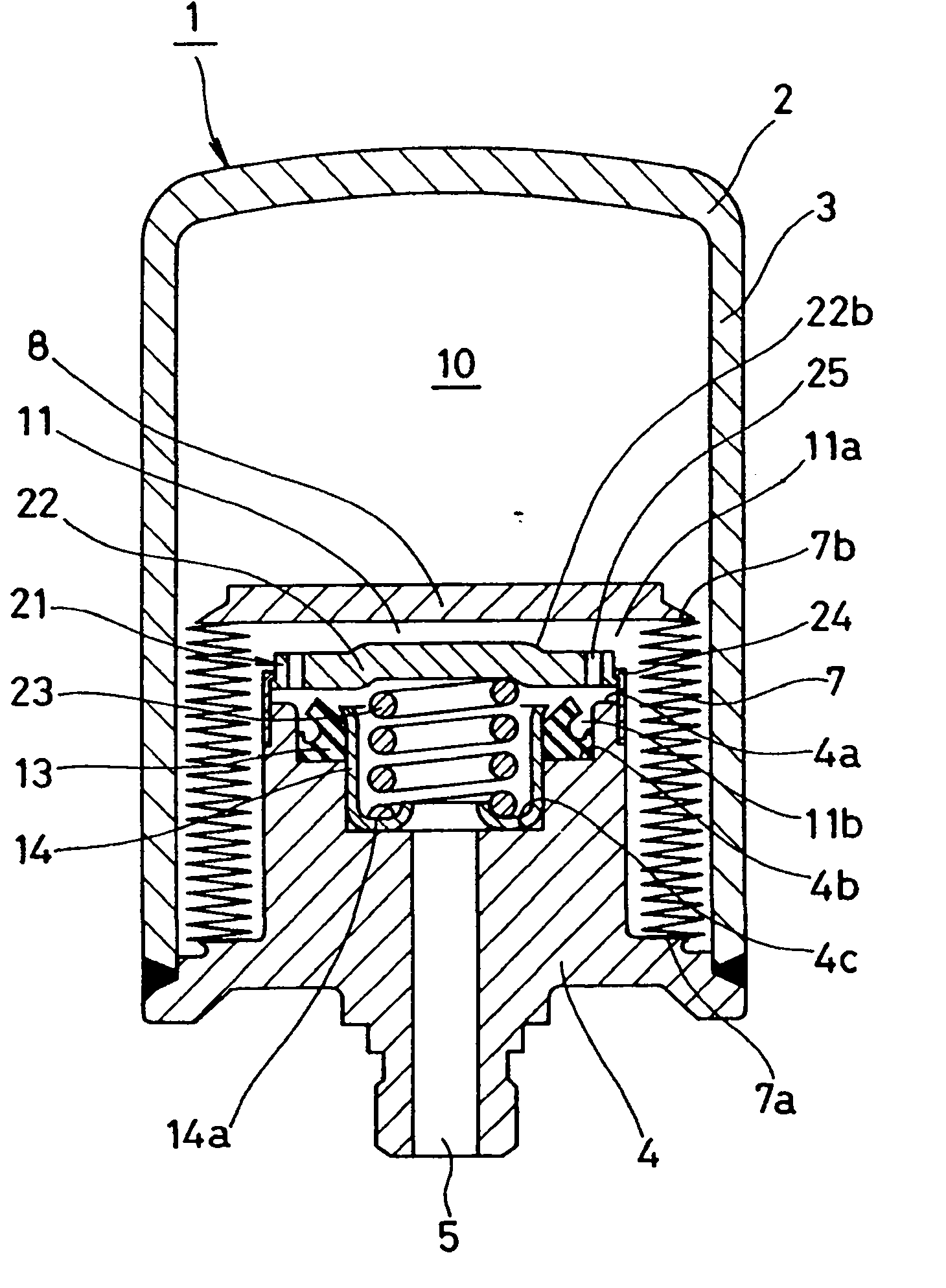

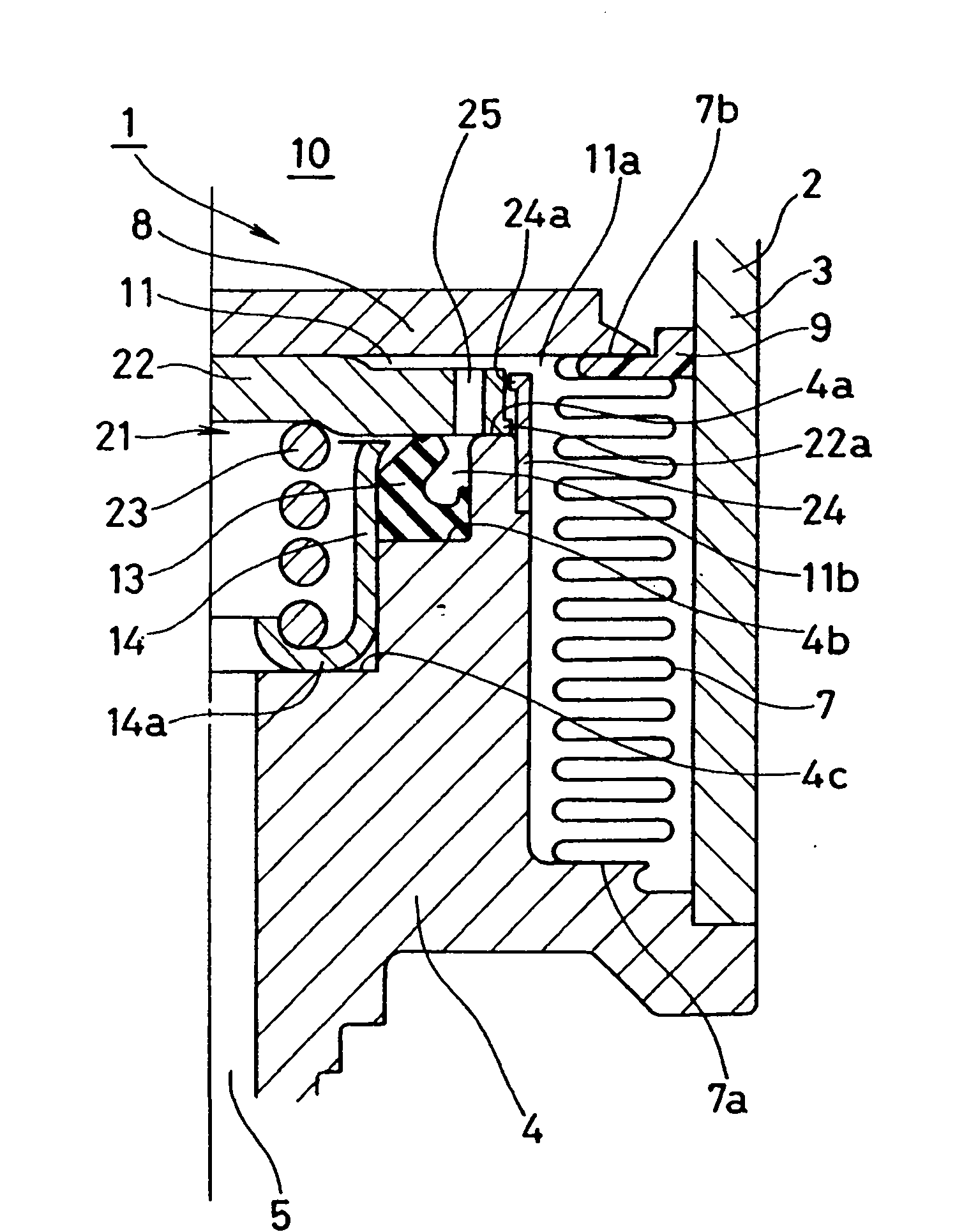

[0098] 1 to 3 show a full section and a partial section of an energy store 1 according to a first embodiment of the invention. Figure 1, Figure 2, and Figure 3 show the states during normal operation, zero drop, and thermal expansion in the zero drop state, respectively.

[0099] The accumulator 1 of the present embodiment is a metal bellows type accumulator using a metal bellows as the bellows 7, and is configured as follows.

[0100] That is, first, an accumulator case 2 having an oil passage 4 connected to a pressure pipe (not shown) is provided, and a bellows 7 is arranged inside the case 2 to separate the inner space of the case 2 into a gas chamber in which high-pressure gas is enclosed. The chamber 10 communicates with the liquid chamber 11 of the passage hole 5 of the oil passage 4 . The casing 2 is formed by combining a bottomed cylindrical cover 3 and an oil passage 4 fixed to an opening at one end of the cover 3, but the proportion and structure of the parts of the...

no. 2 example

[0120] Although the accumulator 1 in the above-mentioned first embodiment is an external gas accumulator, its pressure difference adjustment mechanism 21 can also be applied to an internal gas accumulator. Fig. 4 shows an example thereof, the bellows cover 8 is installed on the fixed end 7a of the bellows 7 of the movable end 7b, and is fixed on the end cover 6 on the top of the shell 2, thereby constituting the inner peripheral side of the bellows 7 as the air chamber 10 and the outer peripheral side It is the inner gas accumulator 1 of the liquid chamber 11. The configuration and operation of the pressure difference adjusting mechanism 21 are the same as those of the first embodiment, so the same reference numerals are given and descriptions thereof are omitted, but the difference is that the communication passage 25 is provided so that the standing portion (cylindrical portion) of the stopper 24 is horizontal. Porous.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com