Chain saw

A technology of chainsaw and sprocket, which is applied to chainsaws, sawing components, sawing equipment, etc., can solve problems such as difficulty in applying force by operators and uncomfortable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

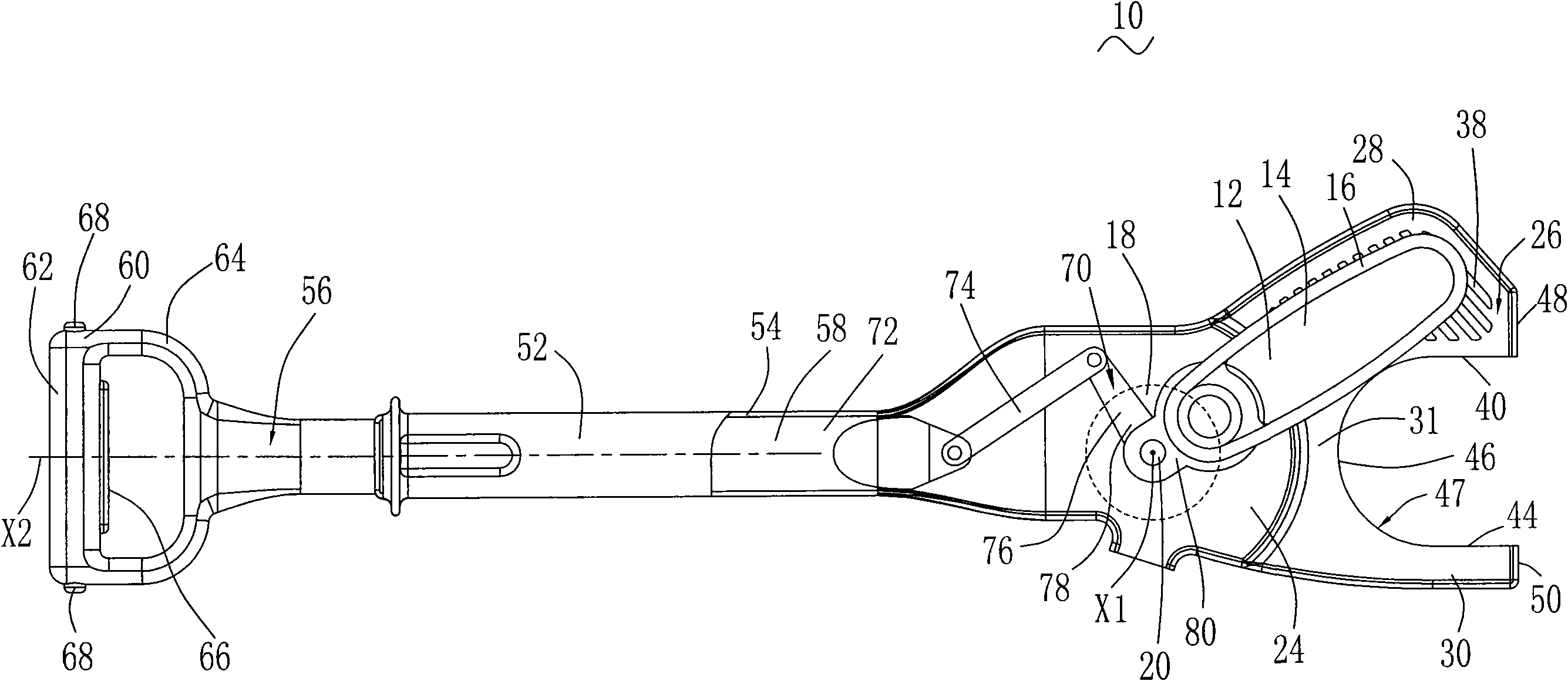

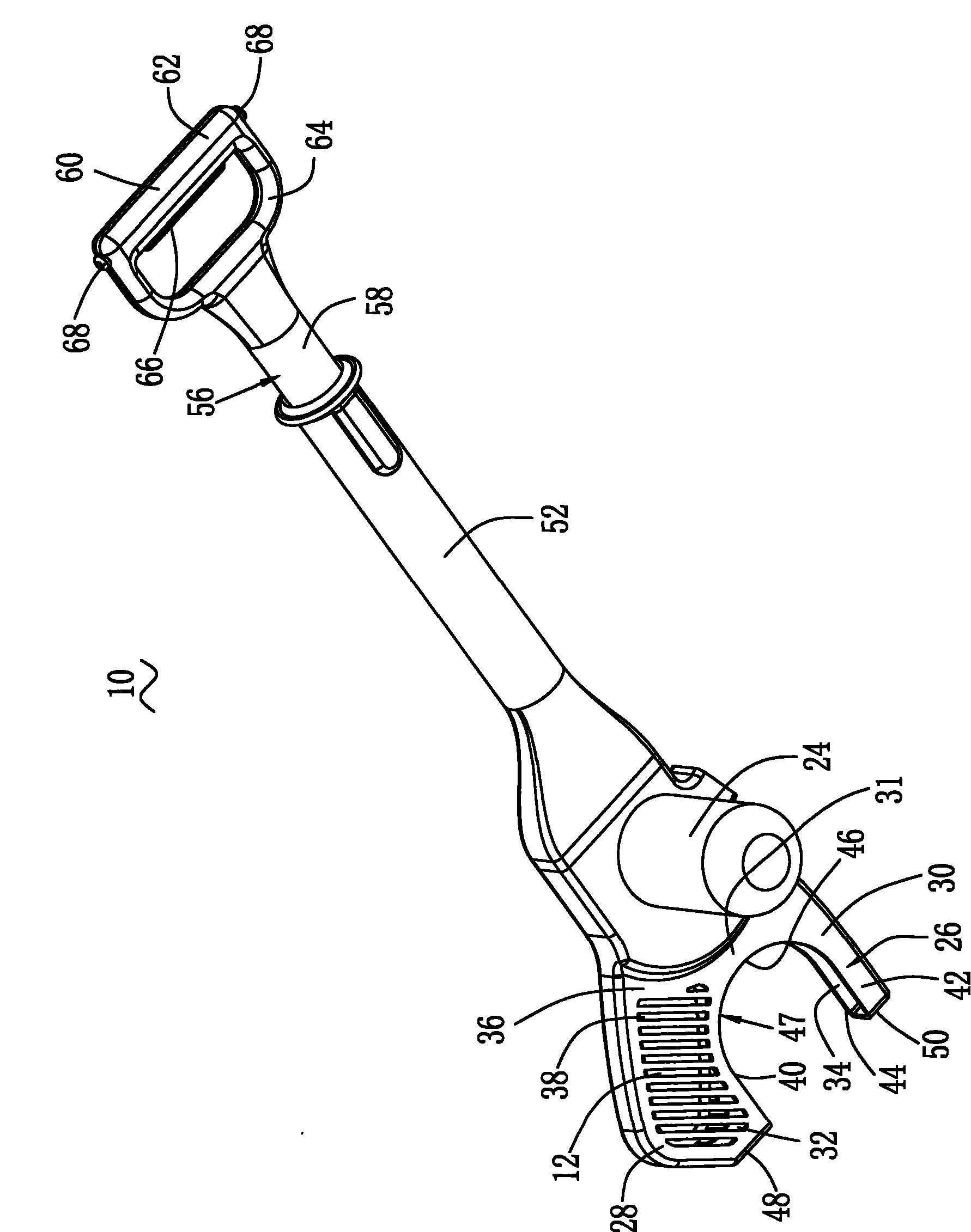

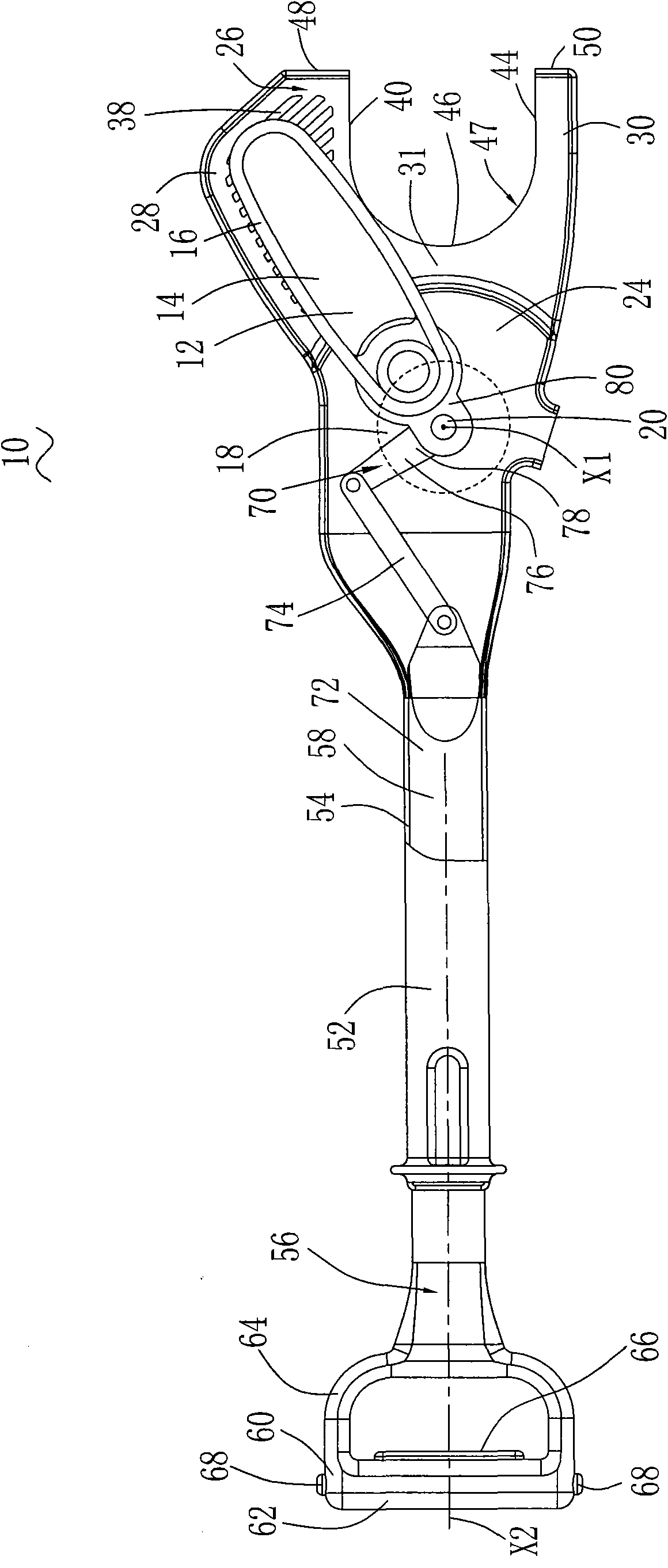

[0066] Referring to FIGS. 1-2 , a chainsaw 10 includes a working head 12 for machining workpieces. The working head 12 includes a support plate 14 and a cutting element mounted on the support plate 14 . In this embodiment, the cutting element is a flexible chain 16 which is installed on the periphery of the support plate 14 and can rotate around the support plate 14 . The plane where the support plate 14 is located is the support plate plane.

[0067] Chainsaw 10 also includes a motor 18 for driving working head 12 such that flexible chain 16 rotates about support plate 14 . The motor 18 has a motor output shaft 20 having a motor output shaft axis X1 which rotates about the motor output shaft axis X1 to drive the flexible chain 16 in rotation about the support plate 14 .

[0068] The motor 18 is accommodated in a motor housing 24. In this embodiment, the motor housing 24 is composed of two half shells. Of course, the motor housing is not limited to this form, and may be other...

no. 2 approach

[0082] Referring to FIG. 8 , this embodiment is basically the same as the first embodiment, except that the slider crank mechanism 70 is replaced by a rack and pinion mechanism 70a. The rack-and-pinion mechanism 70a includes a rack 72a fixedly connected to the handle device 56, and a gear 74a fixedly connected to the support plate 14. By pushing or pulling the handle device 56, the gear 74a will pivot to drive the support plate 14 to pivot. .

no. 3 approach

[0084]Referring to FIG. 9 , this embodiment is basically the same as the first embodiment, except that the slider crank mechanism 70 is replaced by a pulley mechanism 70b. The pulley mechanism 70b includes a pulley 72b and a rope 74b. The rope 74b is sheathed on the pulley 72b. One end of the rope 74b is fixedly connected to the handle device 56, and the other end of the rope 74b is fixedly connected to the motor housing 24. The pulley 72b is connected to the pulley 72b through the connecting rod 76b. The support plate 14 is fixedly connected. During operation, the operator pulls the handle device 56 along the C direction, and the pulley 72b drives the connecting rod 76b to pivot, so that the connecting rod 76b drives the support plate 14 to pivot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com