Technology for preparing oxygen difluoride

A process technology, the technology of oxygen difluoride, applied in the field of production of oxygen difluoride, can solve the problems of poor product quality, complicated production technology, high cost, etc., and achieve the effect of reasonable design and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

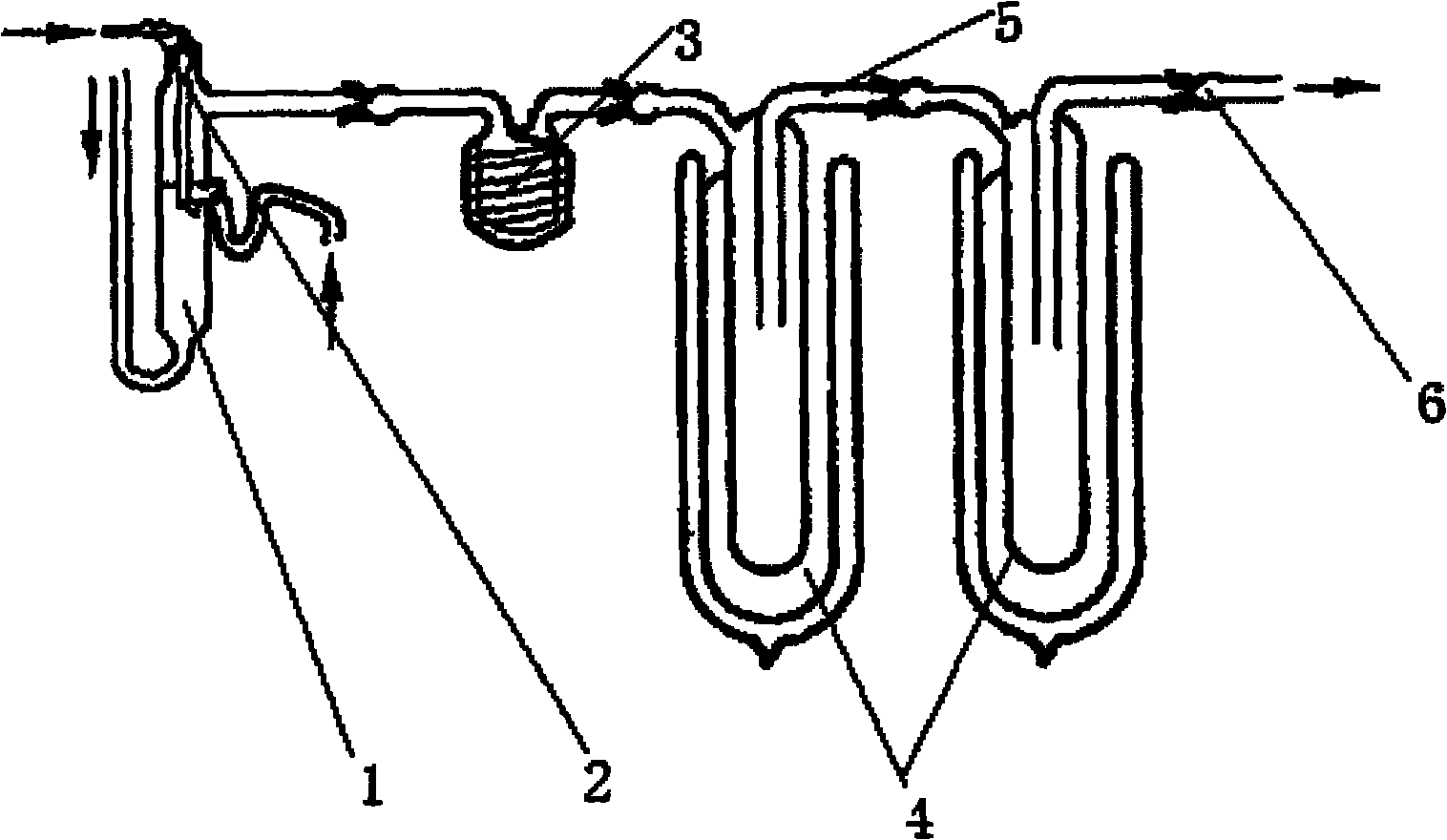

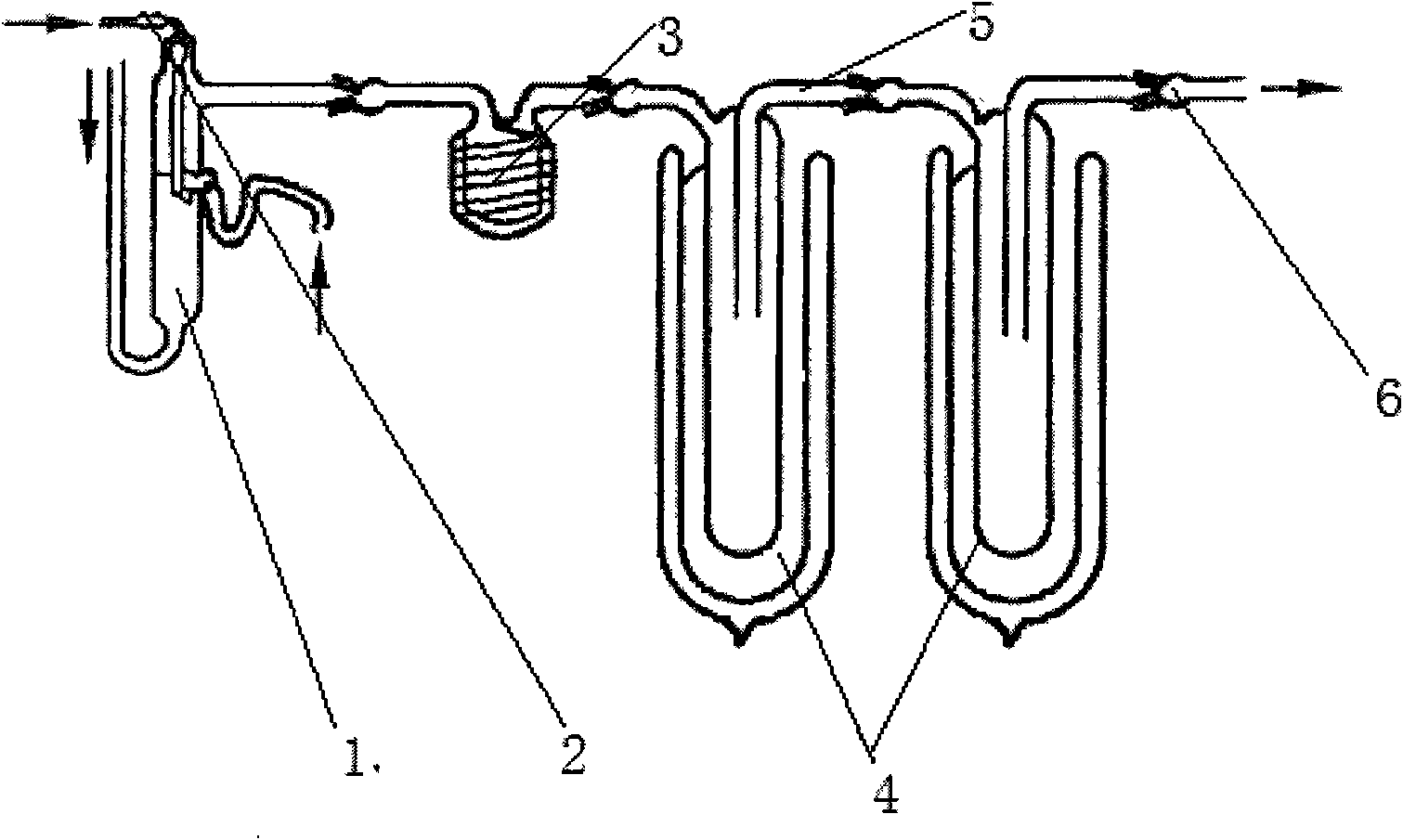

[0010] Referring to Fig. 1, the reactor (1), platinum tube (2), spin tube washing bottle (3), cold trap (4), fume hood (6) are assembled into one body through connecting pipe (5) according to their system functions .

[0011] During use, the gaseous fluorine is fed into 2% sodium hydroxide solution to prepare, with a platinum tube (2) with an internal diameter of about 2mm 2 The air flow passes into the 2% NaOH solution contained in a glass reactor (1) at a speed of 1-3L / h, and the alkali liquor flows out from a higher position storage at a speed of 2L / h, and passes through the reactor (1) ), make the released mixed gas pass through a coil washing bottle (3) filled with water to absorb unreacted F 2 , and then the oxygen difluoride is condensed in two glass gas traps (4) cooled with liquid oxygen through the connecting pipe (5). The product is pumped at -183°C to 20mmHg, so that most of the O dissolved in the liquid oxygen difluoride can be removed 2 , fractionate oxygen di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com