Continuous process for preparing hydrocarbon products through methanol transformation without standby reactor

A technology for the conversion of hydrocarbon products and methanol, which is applied in the continuous process field, can solve the problems of cumbersome operation of regeneration system control and actuators, increased investment in automatic control parts, and lower reliability of equipment operation, so as to simplify the automatic control part and improve stability performance and reliability, and the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

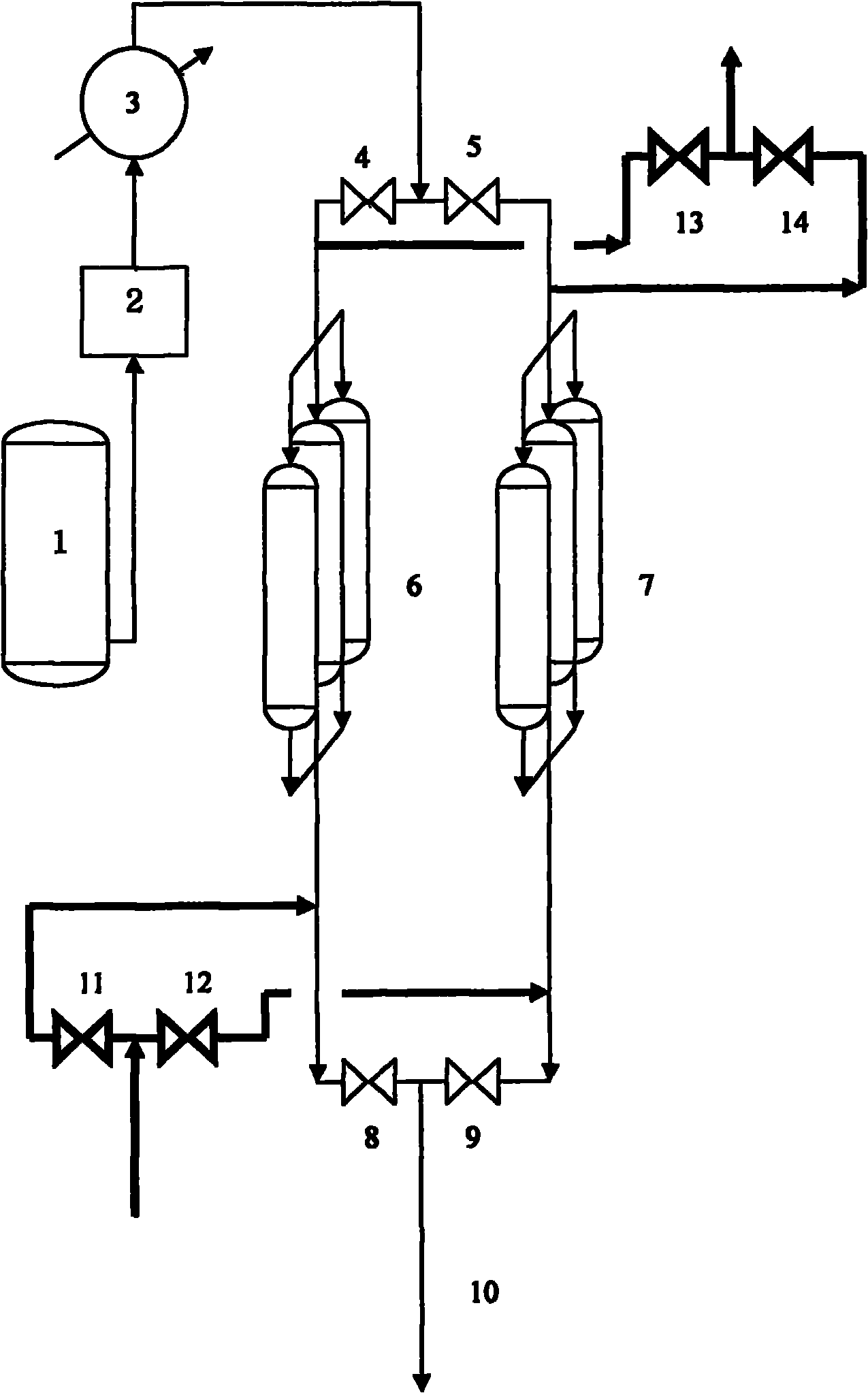

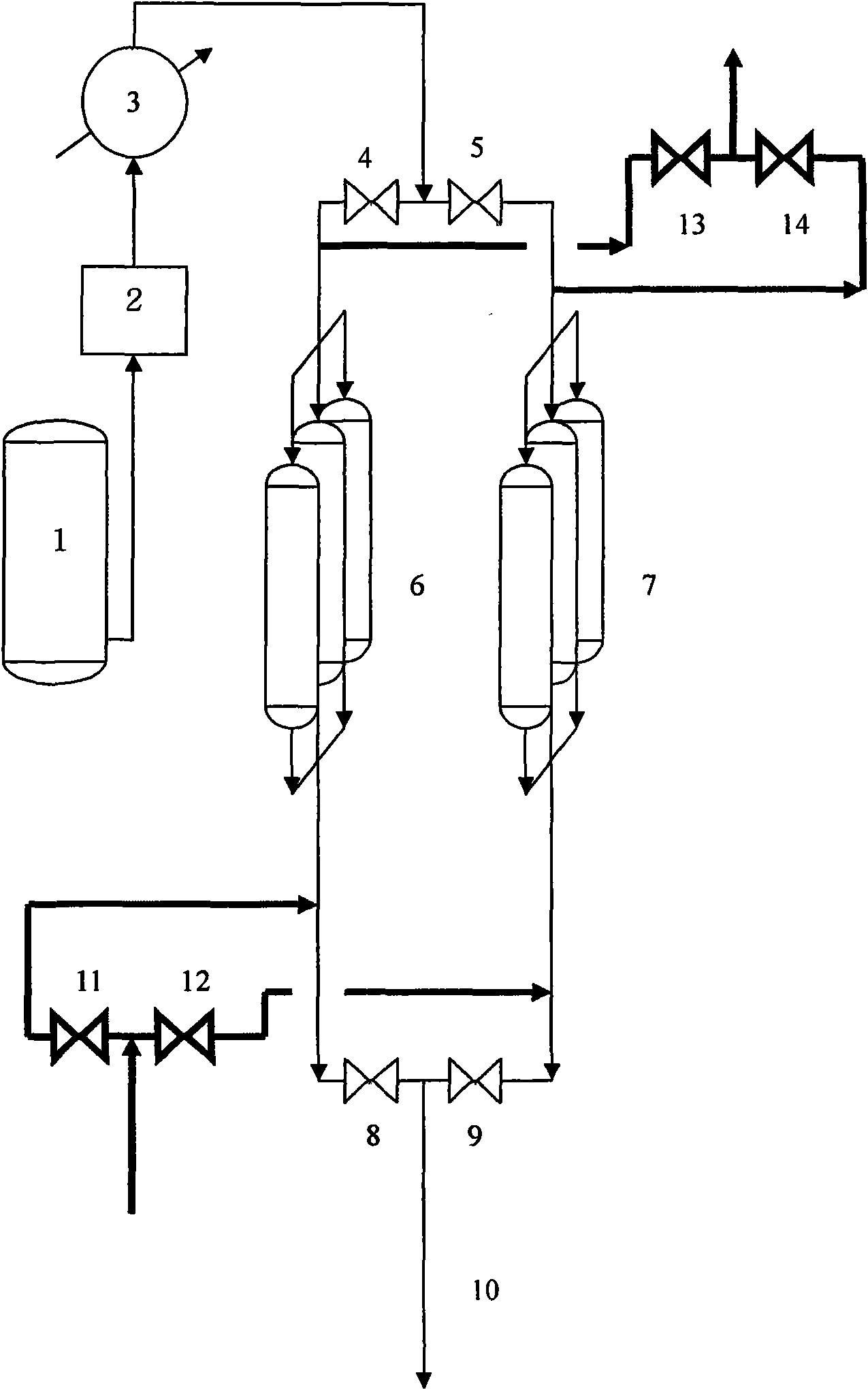

[0022] Embodiment 1 takes the one-step process of methanol conversion to gasoline in a fixed-bed adiabatic reactor as an example, and adopts the process flow of the accompanying drawing. The number of the first group of reactors 6 and the number of the second group of reactors 7 are both 2, and each reactor is filled with 100 kg of methanol conversion to gasoline catalyst (ZSM-5 molecular sieve catalyst). The reaction pressure was 1.6 MPa, the inlet temperature of each reactor was 320°C, and the outlet temperature was 410°C. The specific implementation steps are as follows.

[0023] 1. Turn on the first group of reactors

[0024] As shown in the process flow chart, when starting for the first time, open the reaction material inlet valve (4) and the reaction material outlet valve (8) of the first group of reactors (6), and close the reaction material inlet valve of the second group of reactors (7) (5), the reaction material outlet valve (9), close the valves (11), (12), (13),...

Embodiment 2

[0040] Embodiment 2 takes methanol conversion to produce LPG as an example. Adopt the process flow shown in the accompanying drawing. The number of the first group of reactors 6 and the second group of reactors 7 are 4 units, and each reactor is filled with 50kg of ZSM-5 molecular sieve catalyst for producing LPG from methanol conversion, and the total amount of catalyst loading is 400kg. The methanol flow rate is 800kg / h, the system pressure is 1.0MPa, the inlet temperature of each reactor is 380°C, and the outlet temperature of each reactor is 510°C. Under the condition that reactor 6 and reactor 7 work simultaneously, the mass space velocity of methanol is 2.0h -1 , when one of the catalysts is in the regeneration state, relative to the working catalyst, the methanol mass space velocity is 4.0h -1 . Concrete implementation steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com