Gasoline engine lubricating structure

A lubricating structure and gasoline engine technology, applied in the direction of engine lubrication, pressure lubricants, mechanical equipment, etc., can solve the problems affecting the smooth flow of lubricating oil circulation, poor sensitivity and reliability, and increase the work efficiency of the assembled machine to achieve guarantee Good patency, reliability and good lubricating effect

Inactive Publication Date: 2010-08-25

力帆科技(集团)股份有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional gasoline engine uses a one-way valve composed of a stopper and a valve plate to control the opening and closing of the oil circuit between the crank chamber and the crankshaft gear chamber. Due to the small size of the stopper and the valve plate, the installation is more difficult, which will increase the work efficiency of assembling the whole machine

At the same time, the valve plate is a steel plate, which requires a certain pressure to open, and the sensitivity and reliability are poor, which easily affects the smoothness of the lubricating oil circulation, thereby reducing the effect of the lubrication of the whole machine

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

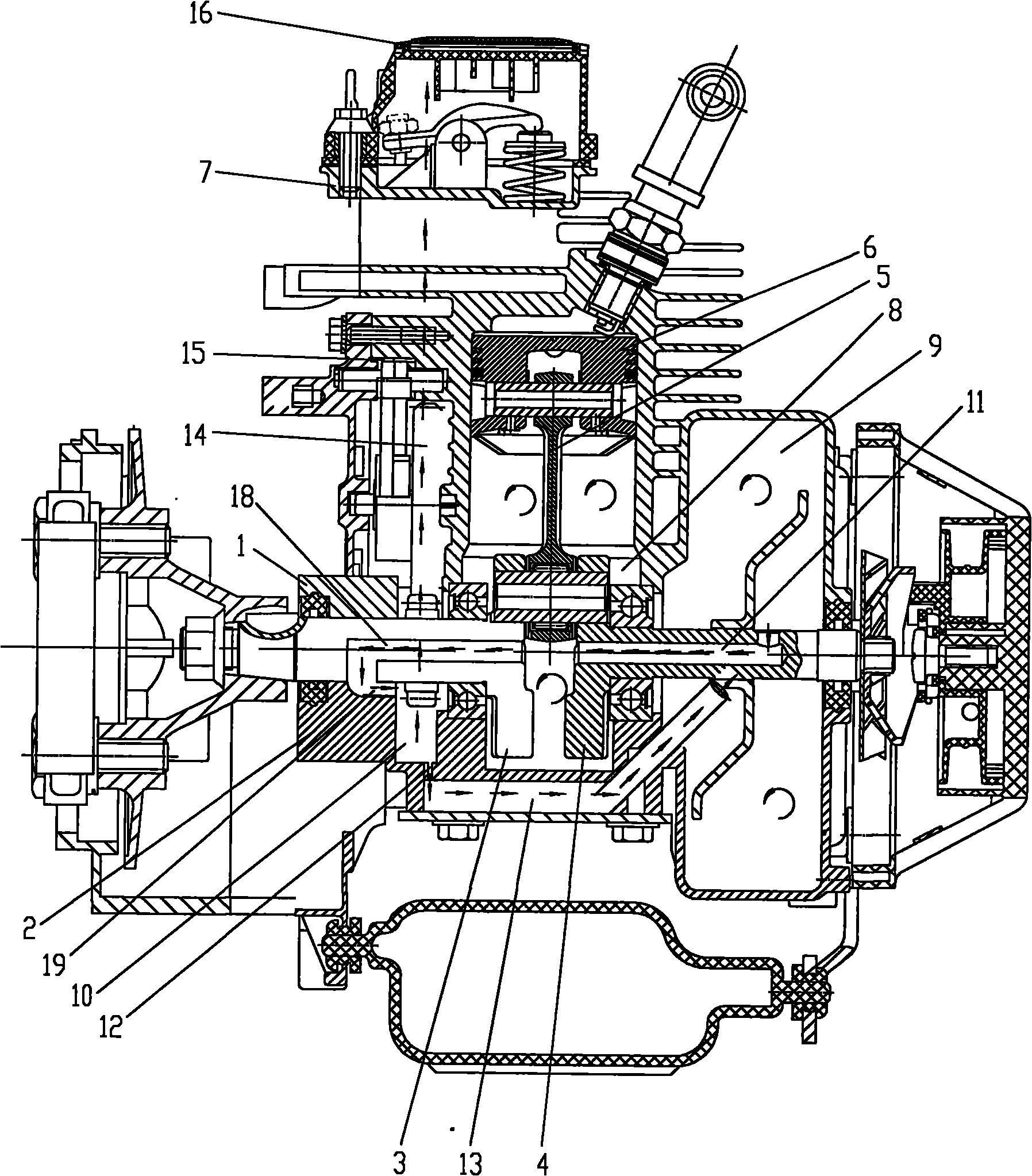

The invention discloses a gasoline engine lubricating structure. Upper and lower crankshaft cases are combined to form a crank chamber, an engine oil chamber and a crankshaft gear chamber; the engine oil chamber is positioned on the right side of the crank chamber and communicated with the crank chamber through a first oil guide passage on a right crank; the crankshaft gear chamber is positioned on the left side of the crank chamber; the bottom of the crankshaft gear chamber is provided with a small hole which is communicated with an oil return passage on the lower crankshaft case; a left crank is provided with a second oil guide passage of which the oil inlet is formed on the end face of the handle part of the left crank; the oil outlet of the second oil guide passage is formed on the outer circumferential surface of the shaft part of the left crank and can be communicated with the crankshaft gear chamber through a third oil guide passage on the lower crankshaft case. The structure can improve the flexibility and reliability for opening or closing the passage between the crank chamber and the crankshaft gear chamber, ensure the smoothness for circular flowing of the lubricating oil and have the characteristics of skillful design, simple structure, low reconstruction cost, good lubricating effect and the like.

Description

technical field The invention belongs to the technical field of general-purpose gasoline engines, and in particular relates to a lubrication system for general-purpose gasoline engines. Background technique The upper and lower crankcases of the general-purpose gasoline engine are combined to form a crank chamber, an oil chamber and a crank gear chamber. The oil chamber is located on the right side of the crank chamber. There is an oil hole connected to the crankshaft gear chamber at the bottom of the crank chamber. A stopper and a valve plate are installed in the oil hole. The stopper and valve plate act as a check valve to ensure that the lubricating oil flows from the Chamber to crankshaft gear chamber unidirectional flow. The crank gear chamber is located on the left side of the crank chamber, and the bottom of the crank gear chamber has a small hole to communicate with the oil return passage on the lower crankcase, and a cam connected to it is arranged above the crank g...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F01M1/04

Inventor 罗元波程应维

Owner 力帆科技(集团)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com