Oil tank bracket and single-cylinder horizontal type evaporative type diesel engine using same

An evaporative, diesel engine technology, applied in the direction of engine components, machines/engines, charging systems, etc., can solve the problems of unstable distance, poor distance accuracy, and reduce installation distortion stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

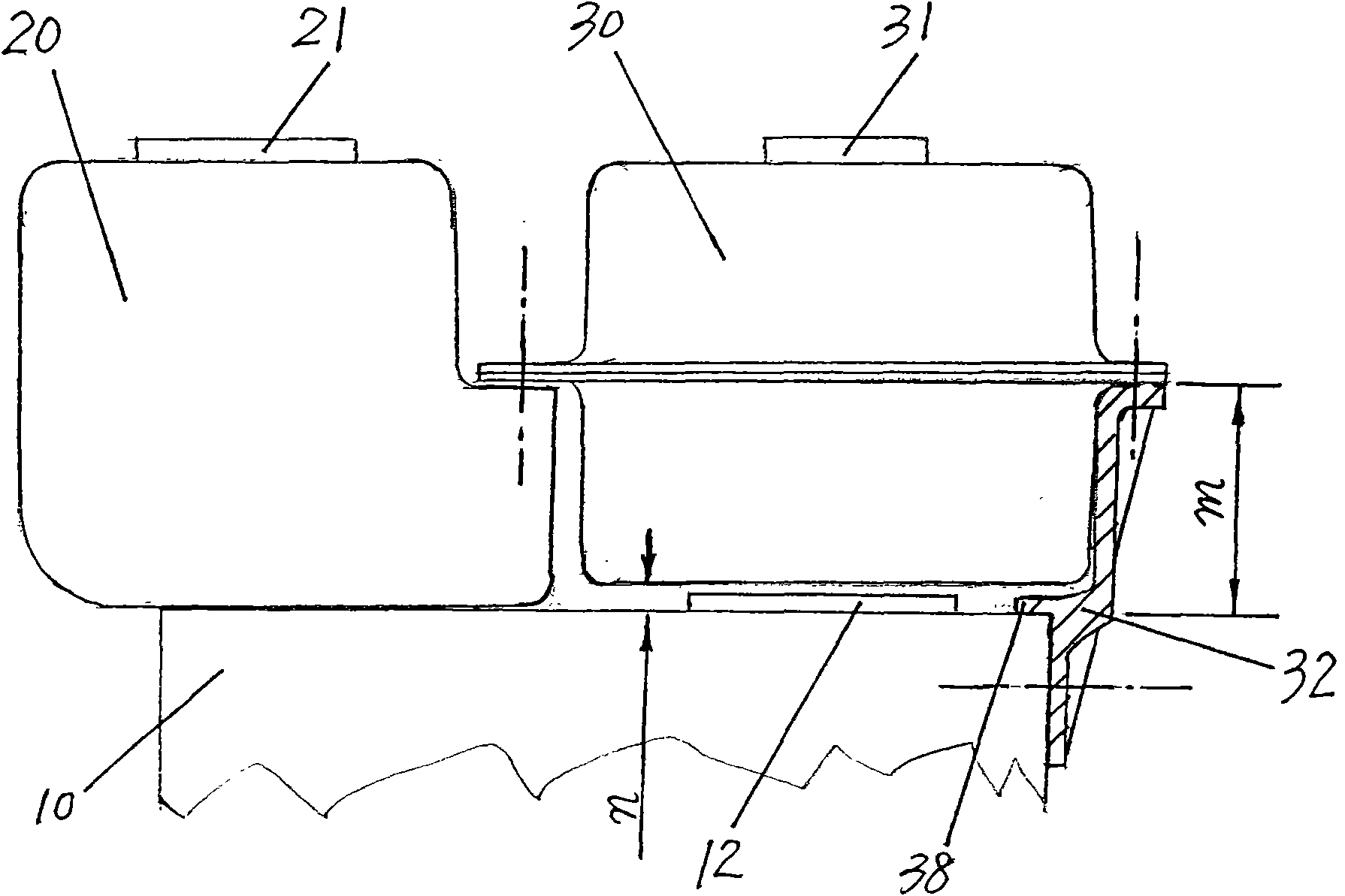

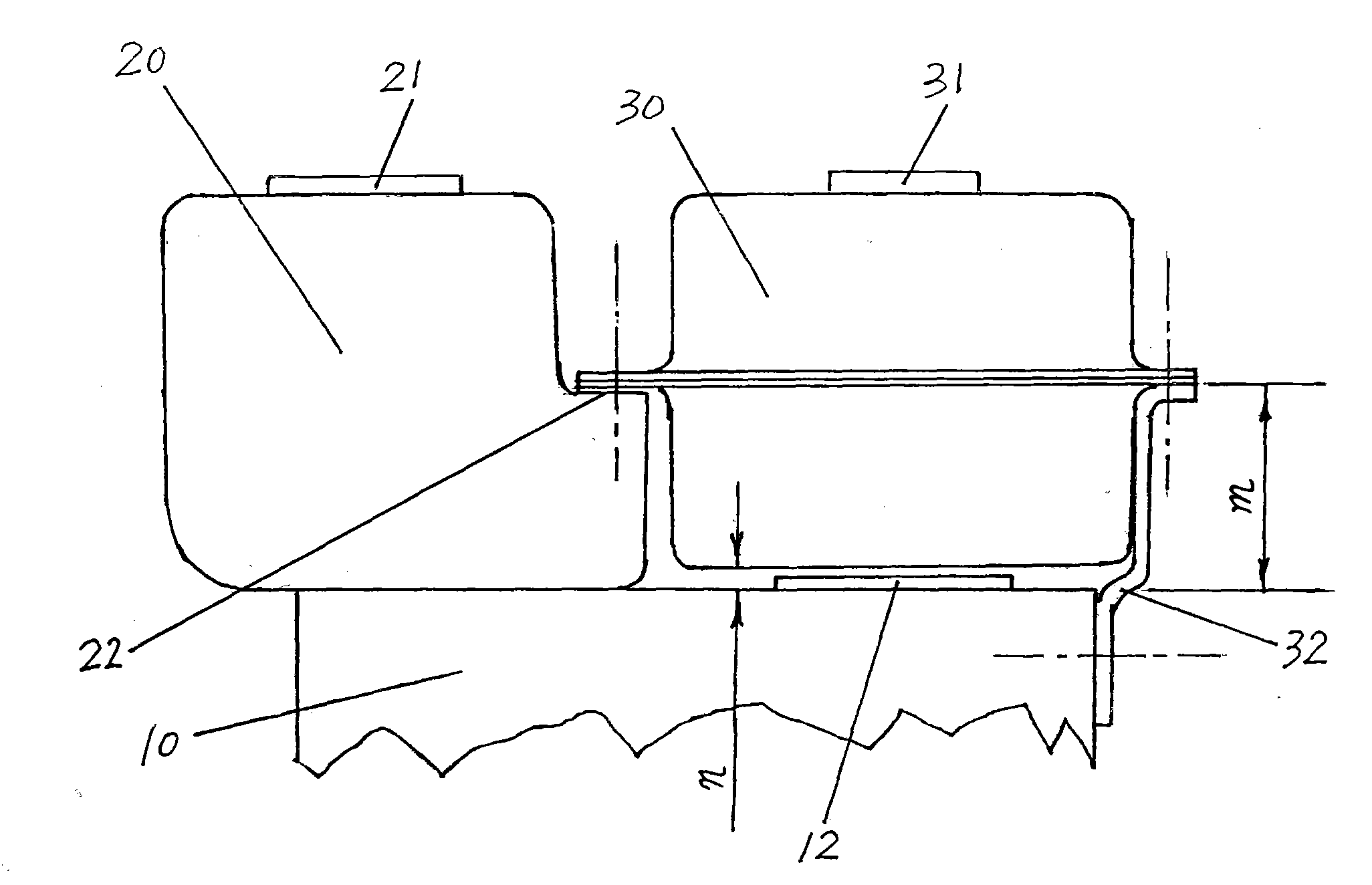

[0016] In Fig. 1, the water tank (20) is installed on the body (10). The upper cover (12) is installed on the body (10) and covers the balance shaft hole. The left end of the fuel tank (30) is lapped on the water tank plane (22), and the upper plane of the support (32) supports the right end of the fuel tank (30) along the mouth and is connected with the right end of the fuel tank (30) by welding, screwing or riveting, and the support ( 32) The lower vertical facade is close to the vertical facade of the body (10) and is fastened with the body (10) by bolts. The vertical distance from the upper plane of the body (10) to the upper plane of the support (32) is (m ), the vertical distance from the upper plane of the body (10) to the bottom of the fuel tank (30) is (n).

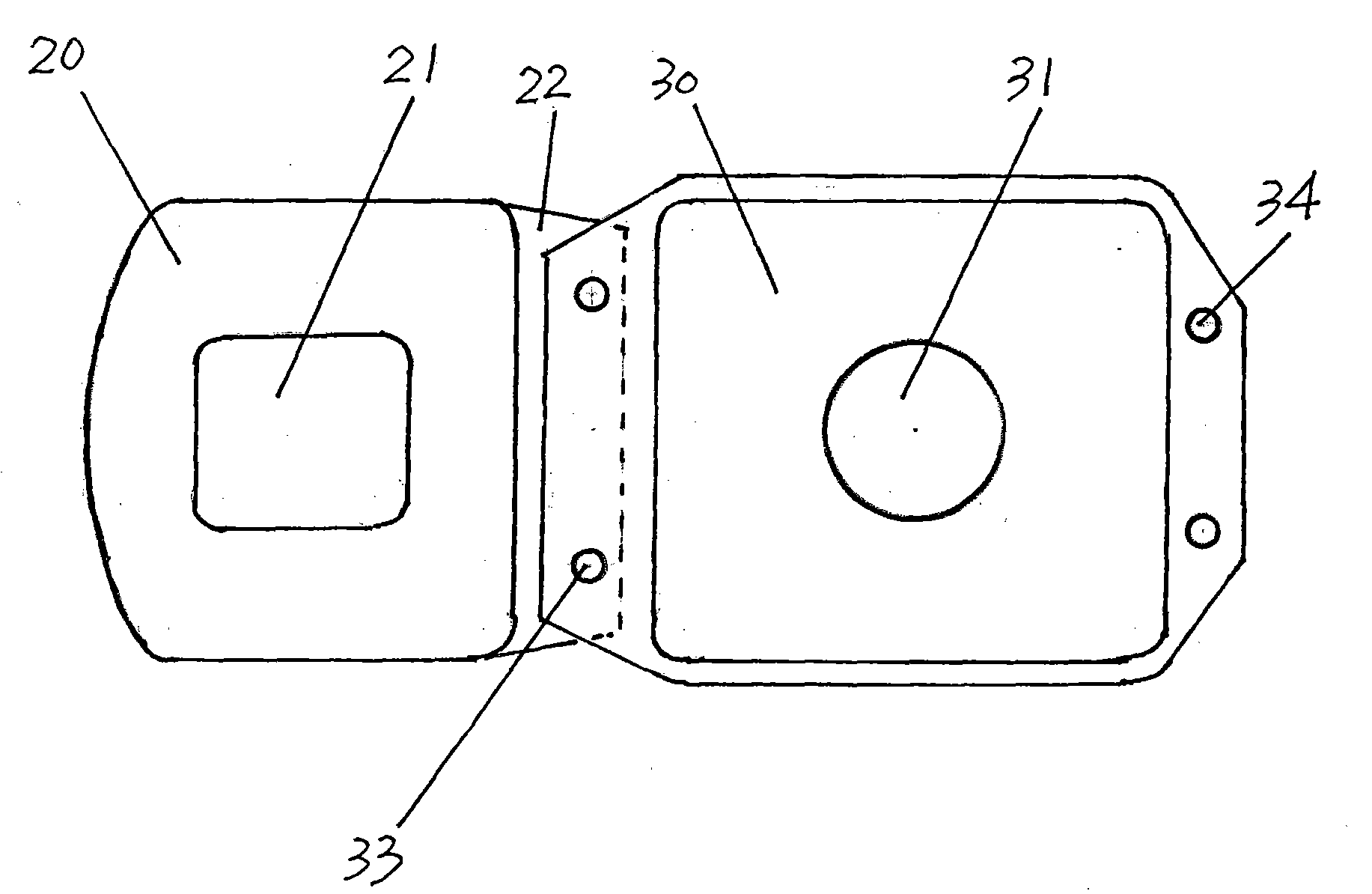

[0017] In Fig. 2, the edge of the fuel tank (30) is superimposed on the plane (22) of the water tank of the water tank (20) overlapping the fuel tank, two fastening bolt holes (33) are provided, and the edge of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com