Oil-pressure chain combined type push-and-pull vehicle mechanism

A technology for pushing and pulling a kiln car and pulling a kiln car, which is applied to the pushing and pulling device of a kiln car and in the field of pushing, can solve the problems of collapse of goods, single action of equipment, and increase of production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

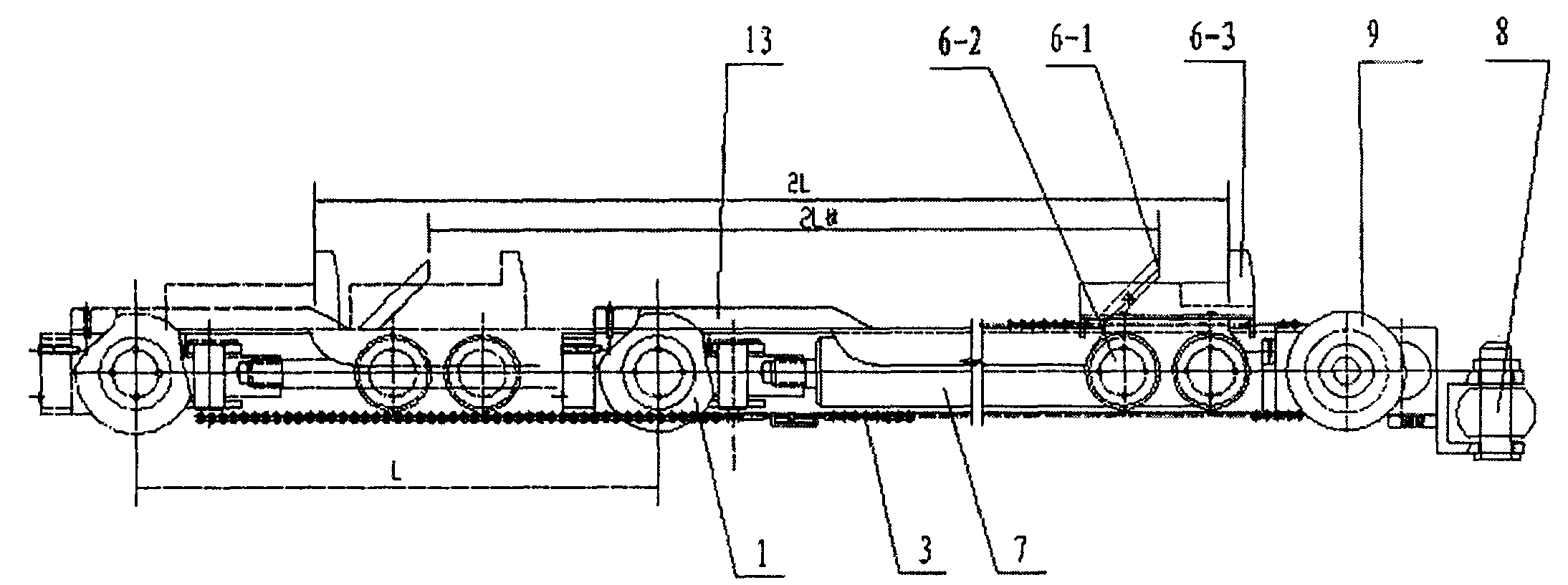

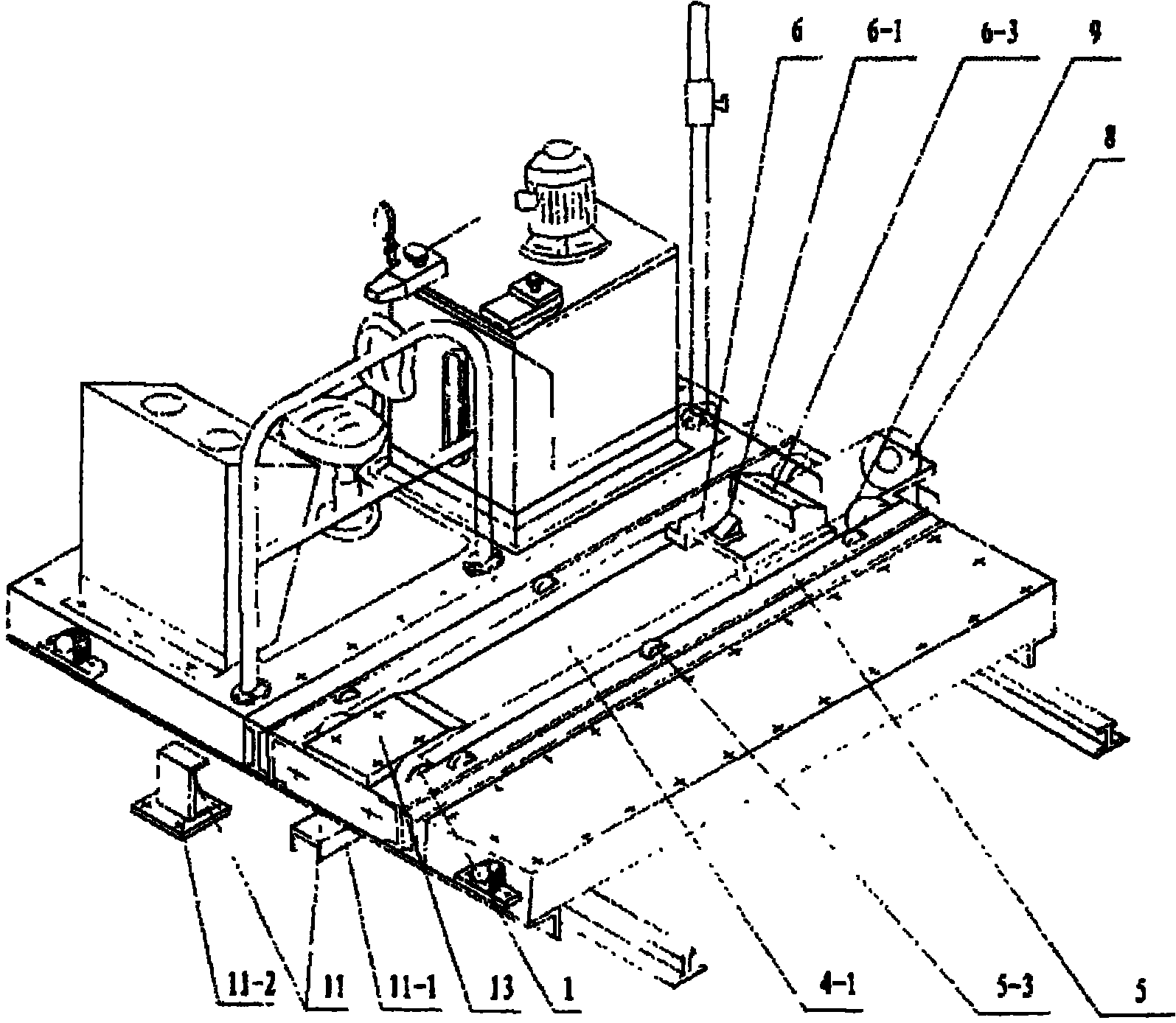

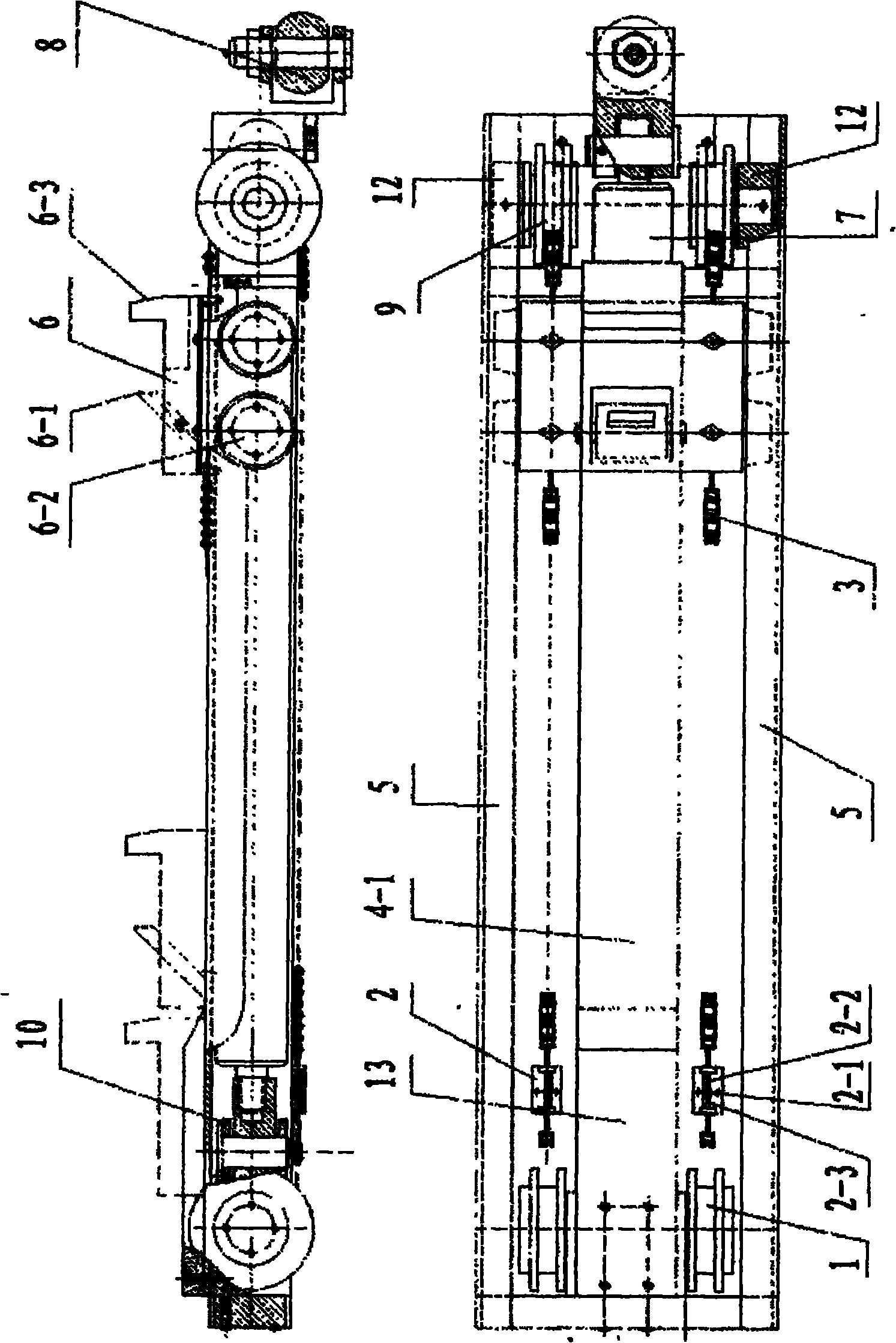

[0012] The main working principle of the present invention is: the trolley travels to the working point. When the work of pulling the cart starts, the oil cylinder 7 pushes the front pulley 1, thereby driving the chain 3 to move at twice the stroke of the cylinder piston, and the push-pull trolley 6 follows the chain 3 to move forward at the same speed. 6-1 After being pressed down by the push-pull plate on the kiln car, the lower part is equipped with a repeating position, and the travel switch that feeds back the travel of the pull car is activated. On, completed the work of pulling the cart. The trolley continues to drive to the unloading point and starts to push the cart. The push plate 6-3 on the push-pull trolley cooperates with the movable block 6-1 to push the push-pull plate of the kiln car, and the kiln car advances accordingly. The bottom of the movable block 6-1 on the top is lifted by the convex plate 13, and the fixed push plate 6-3 on the push-pull trolley push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com