High temperature and high pressure electrical stability tester

A high-voltage, stable technology, applied in the direction of testing dielectric strength, etc., can solve the problems of different mud and can not truly reflect the downhole situation, and achieve the effect of simple structure, good repeatability and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

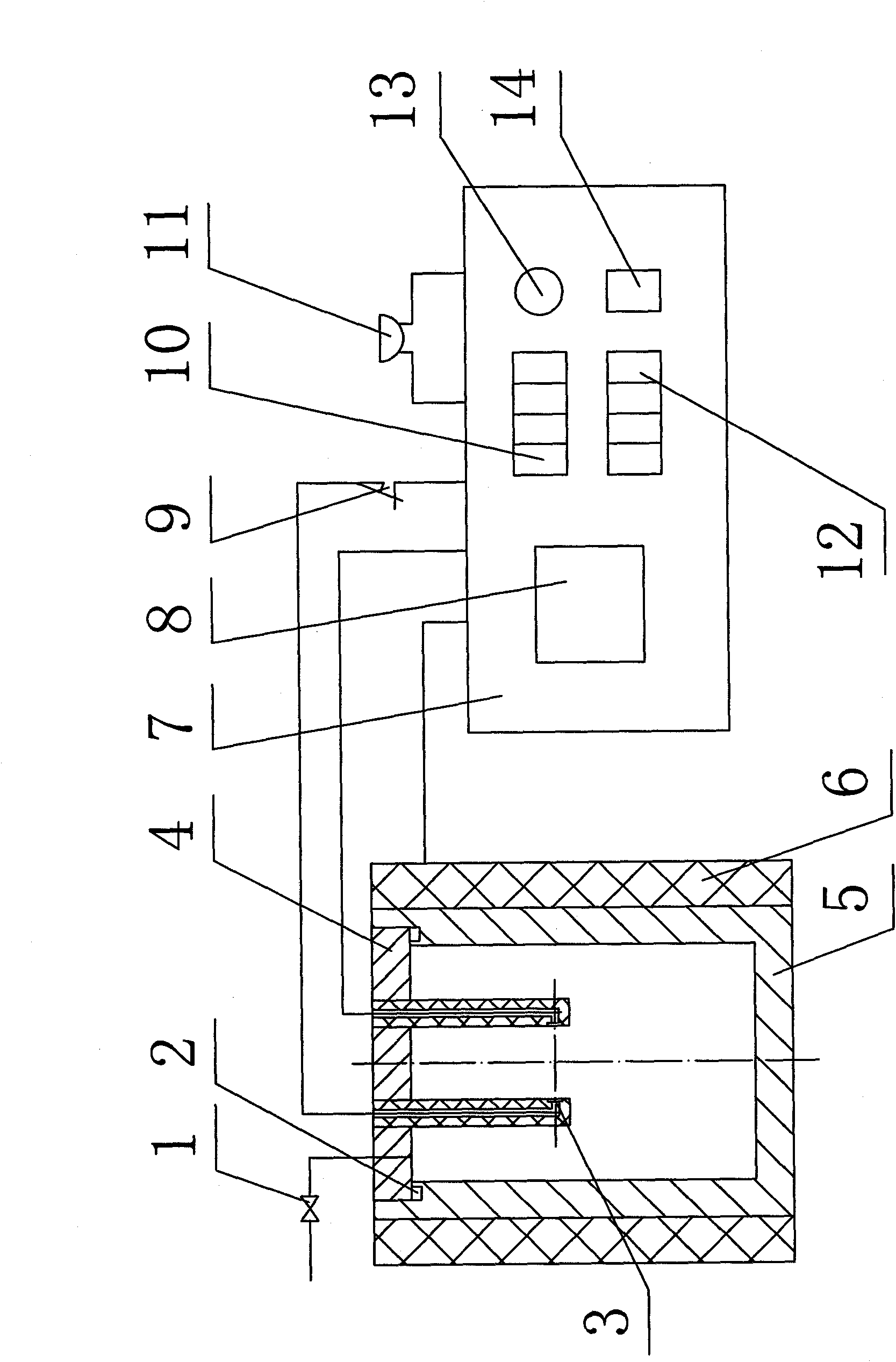

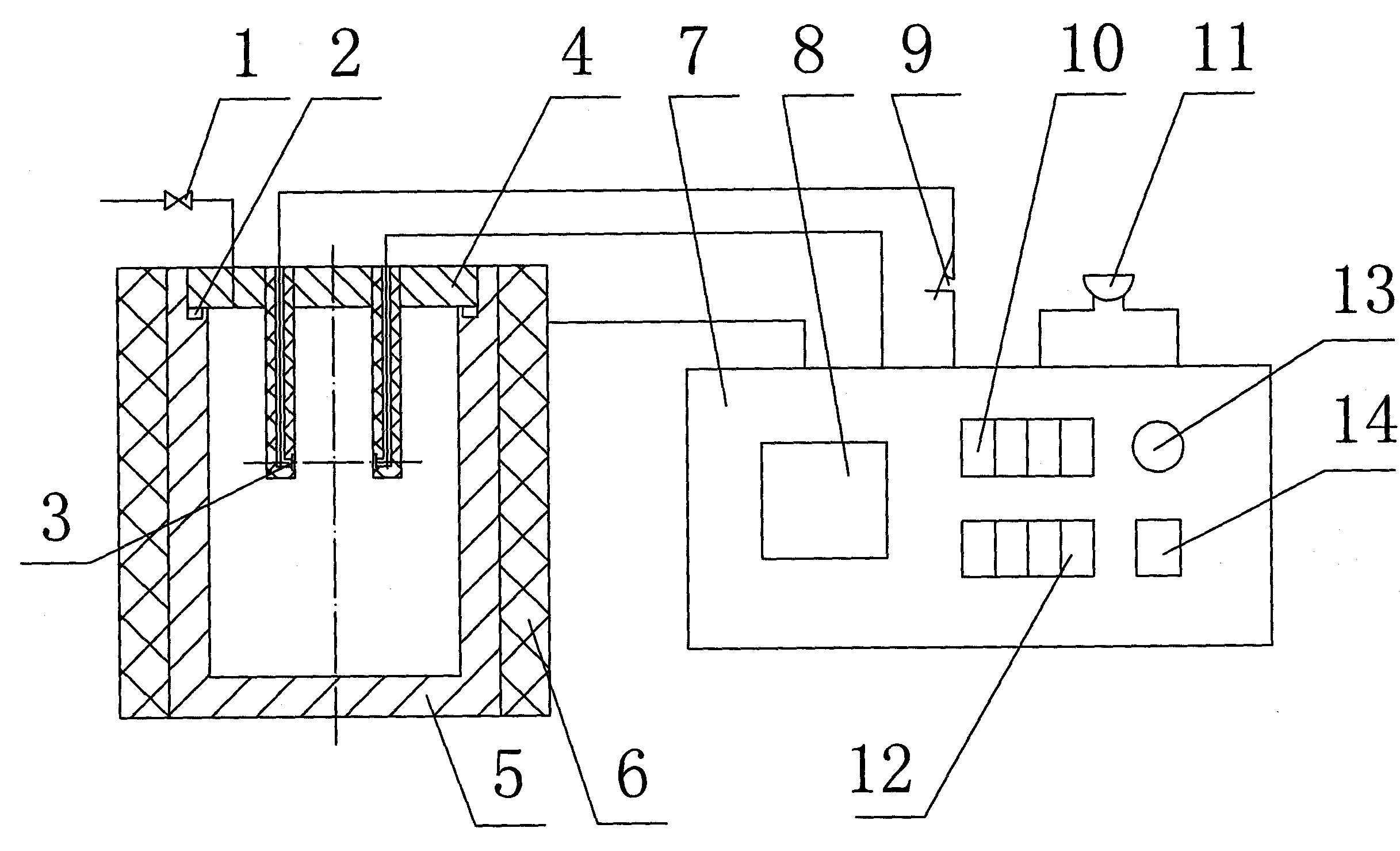

[0011] The high-temperature and high-voltage electrical stability tester is composed of a pressurized valve 1, a probe electrode 3, a high-temperature kettle cover 4, a high-temperature kettle body 5, a heating sleeve 6, and a voltage control device 7. The outer wall of the high-temperature kettle body 5 is covered with Heating sleeve 6, high temperature kettle cover 4 is installed on the top of high temperature kettle body 5, high pressure seal 2 is installed between high temperature kettle cover 4 and high temperature kettle body 5, and two probe electrodes are arranged at the center of high temperature kettle cover 4 3. The electrodes of probe electrode 3 are made of silver alloy, and the electrodes are embedded in the high-temperature-resistant polytetrafluoroethylene probe, so that the insulation performance is very good. A high-pressure pipe is provided on the high-temperature kettle cover 4 on the side of the probe electrode 3, and a pressurization valve 1 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com