Energy efficiency optimizing and dispatching system for cold, heat and electricity triple supply equipment

A technology of combined cooling, heating and power supply and optimal scheduling, applied in the energy industry, electrical program control, comprehensive factory control, etc., can solve problems such as energy supply exceeding load demand, low energy efficiency, energy waste, etc. The effect of avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

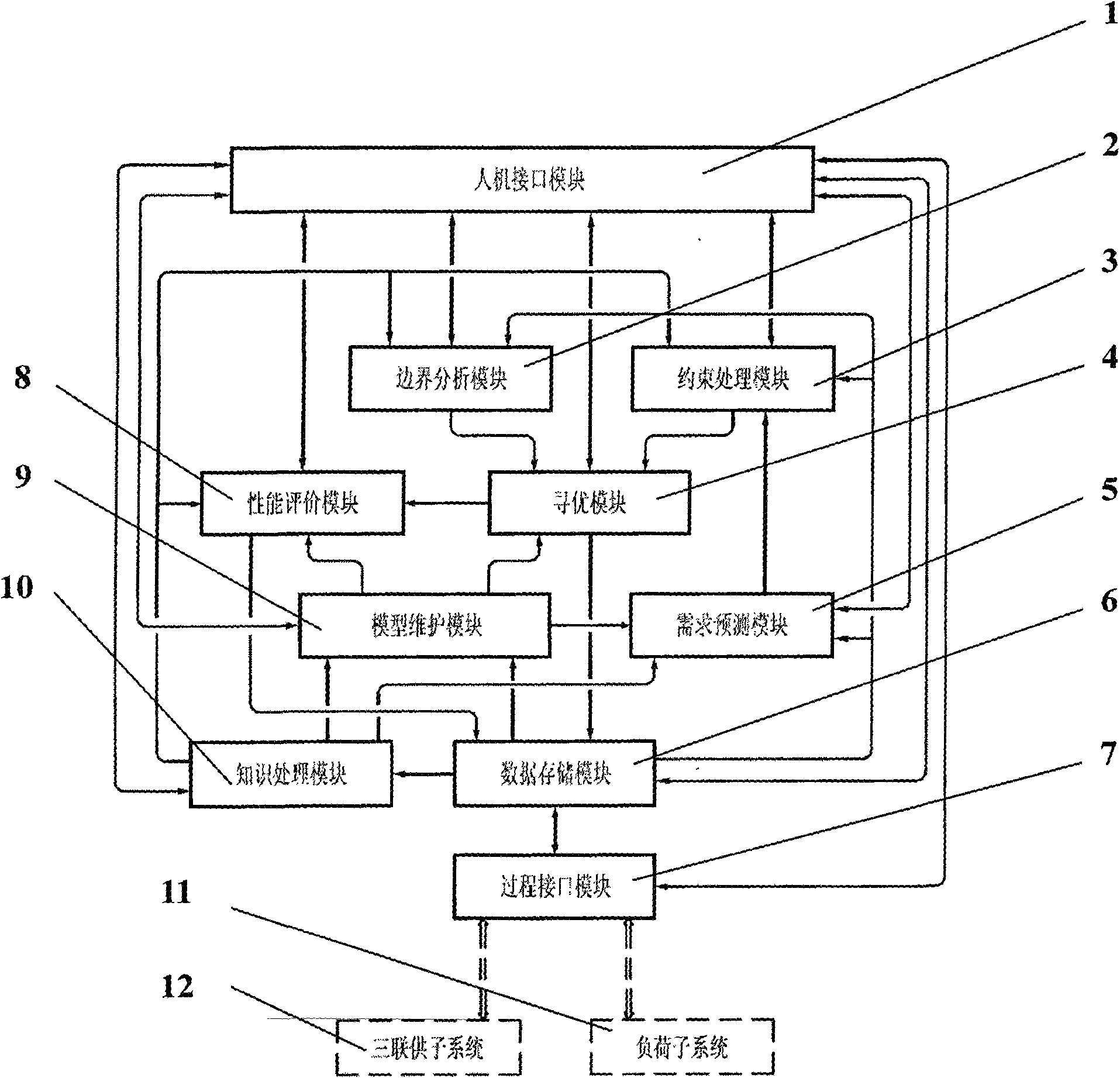

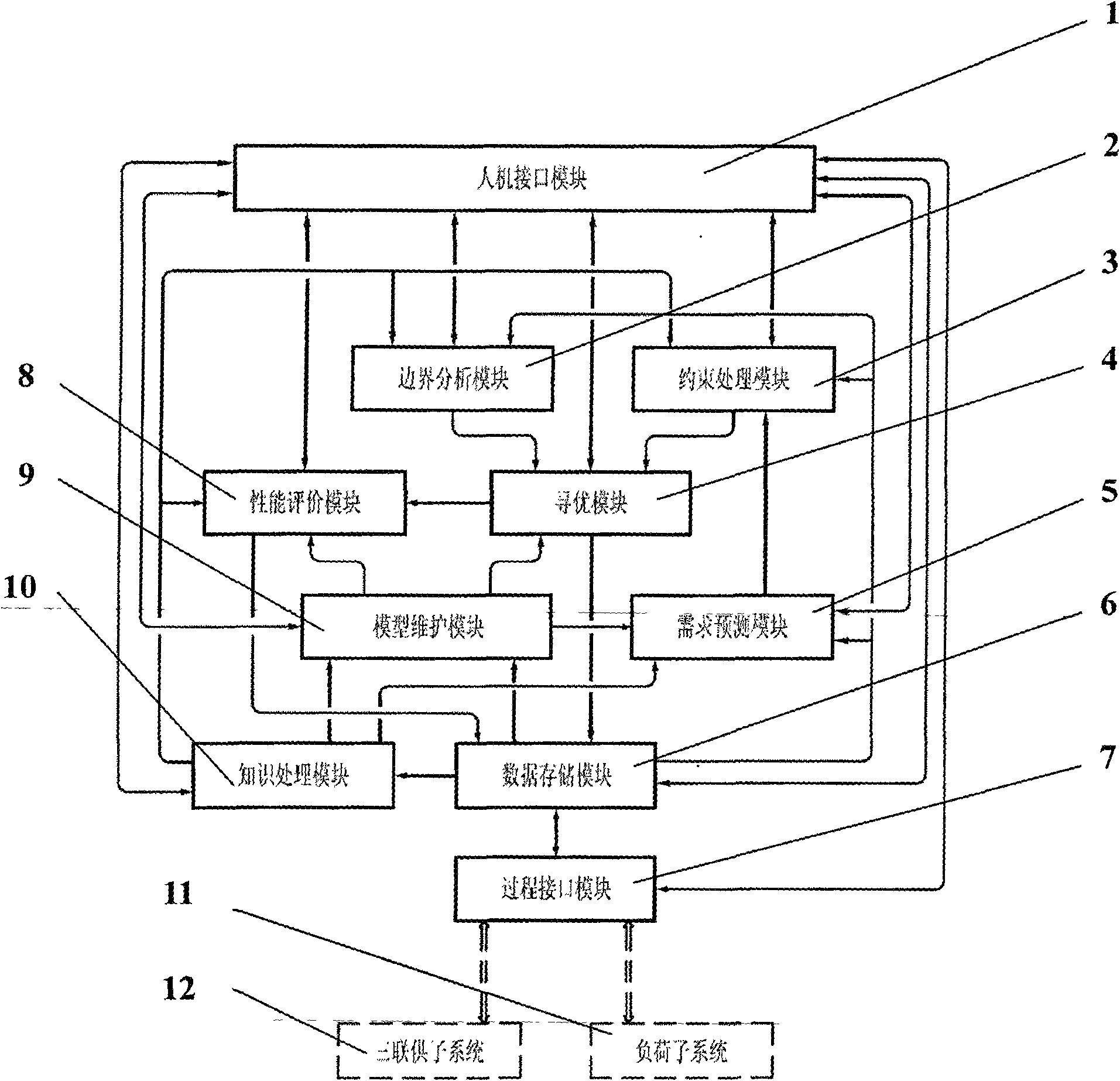

[0018] As shown in Figure 1, the energy efficiency optimization scheduling system of the combined cooling, heating and power supply system of the present invention is connected with the triple supply subsystem 12 and the load subsystem 11 respectively through the process control module, and its functional modules include: human-machine interface module 1, demand Prediction module 5, boundary analysis module 2, constraint processing module 3, optimization module 4, performance evaluation module 8, model maintenance module 9, knowledge processing module 10, data storage module 6, process interface module 7.

[0019] The connections between the modules are as follows:

[0020] The man-machine interface module 1 is the information hub of the optimization scheduling system, and has two-way information and data connections with other functional modules. The data storage module 6 is the data storage center of the optimization scheduling system, and also has two-way information and da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com