Method and device for cooling machine cabinet

A heat dissipation device and heat dissipation method technology, which is applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of not being able to guarantee the level state and the decline of heat dissipation effect, and achieve the effects of saving manpower, improving heat dissipation effect, and stable heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

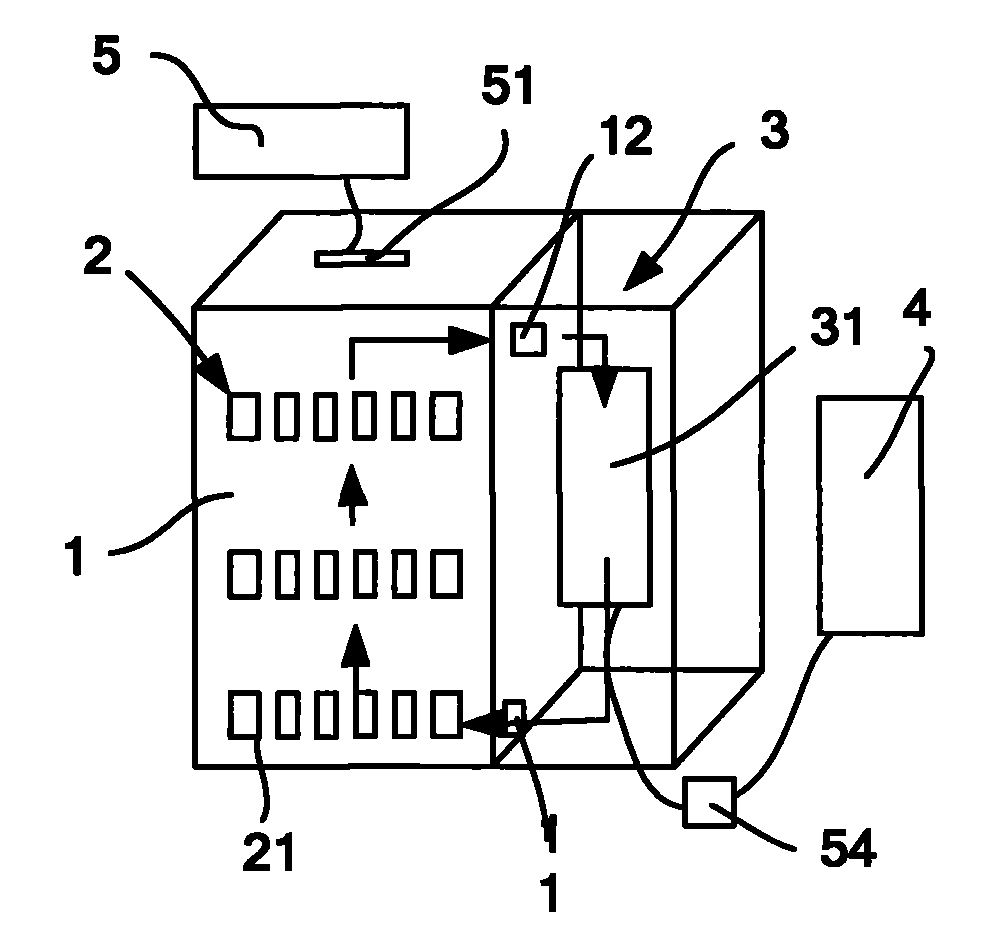

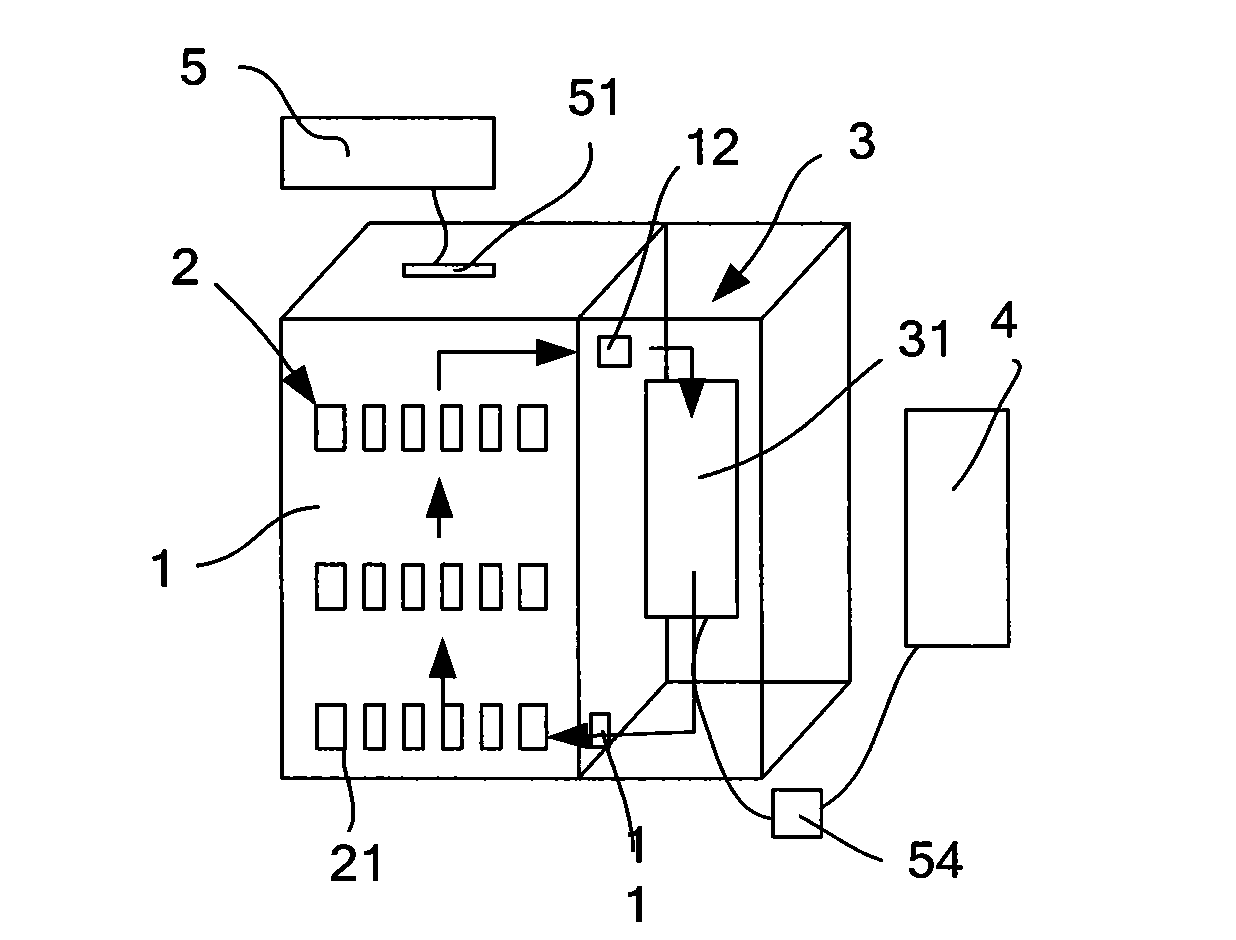

[0039] The invention provides a method for heat dissipation of a cabinet, comprising the following steps:

[0040] (1) Enter the cold air into the cabinet from the lower part of the cabinet;

[0041] (2) The cold air is conveyed from bottom to top in the cabinet, and cools and dissipates the heating elements in the cabinet;

[0042] (3) Discharge the hot air heated up by heat exchange from the upper part of the cabinet;

[0043] (4) cooling the discharged hot air;

[0044] (5) The cooled hot air becomes cold air, and then enters the cabinet from the lower part of the cabinet, so that the cabinet is circulated for heat dissipation.

[0045] This method takes advantage of the natural rising characteristics of hot air, and then designs a multi-layer fan group inside the cabinet to form a vertical air supply channel. This method greatly improves cooling efficiency and energy saving.

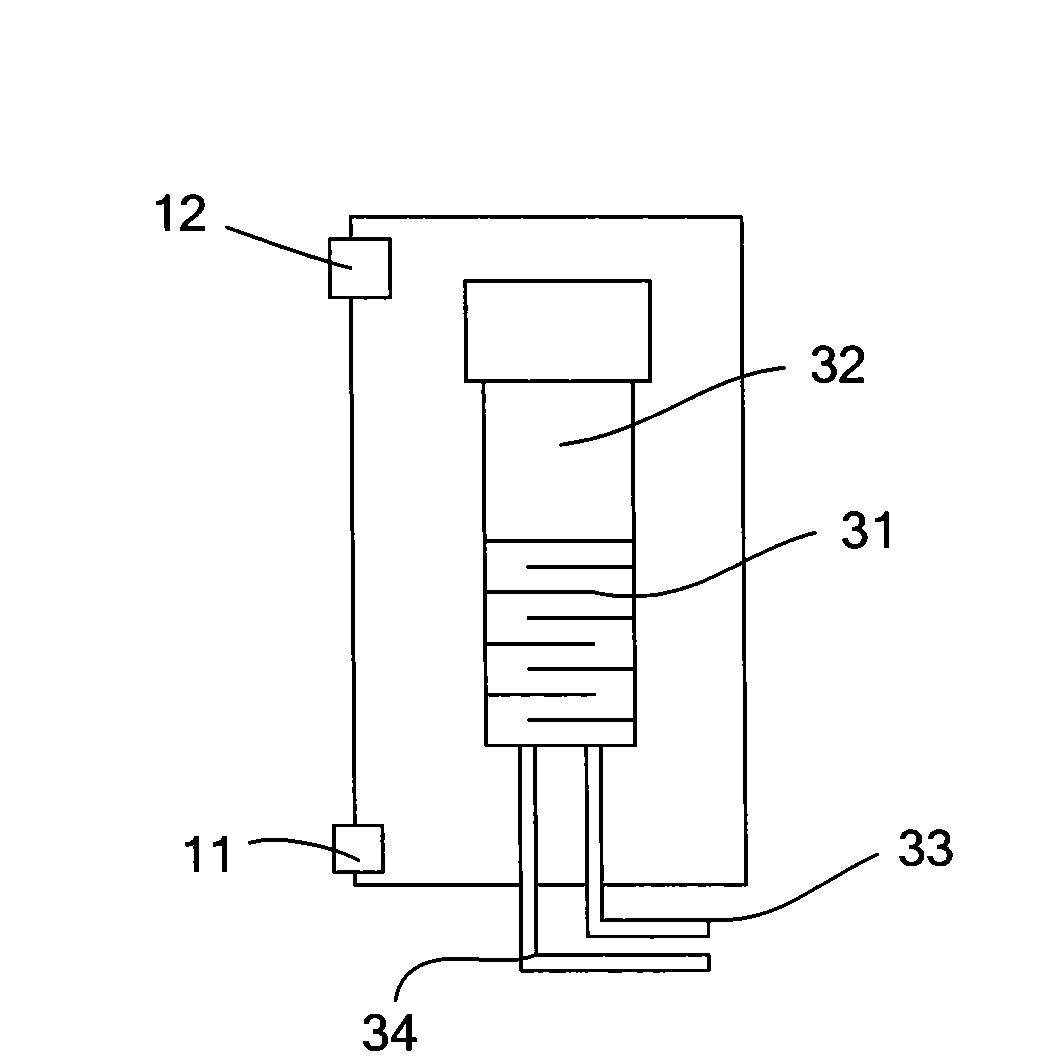

[0046] As shown in Figures 1-4, the present invention also provides a cabinet cooling device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com