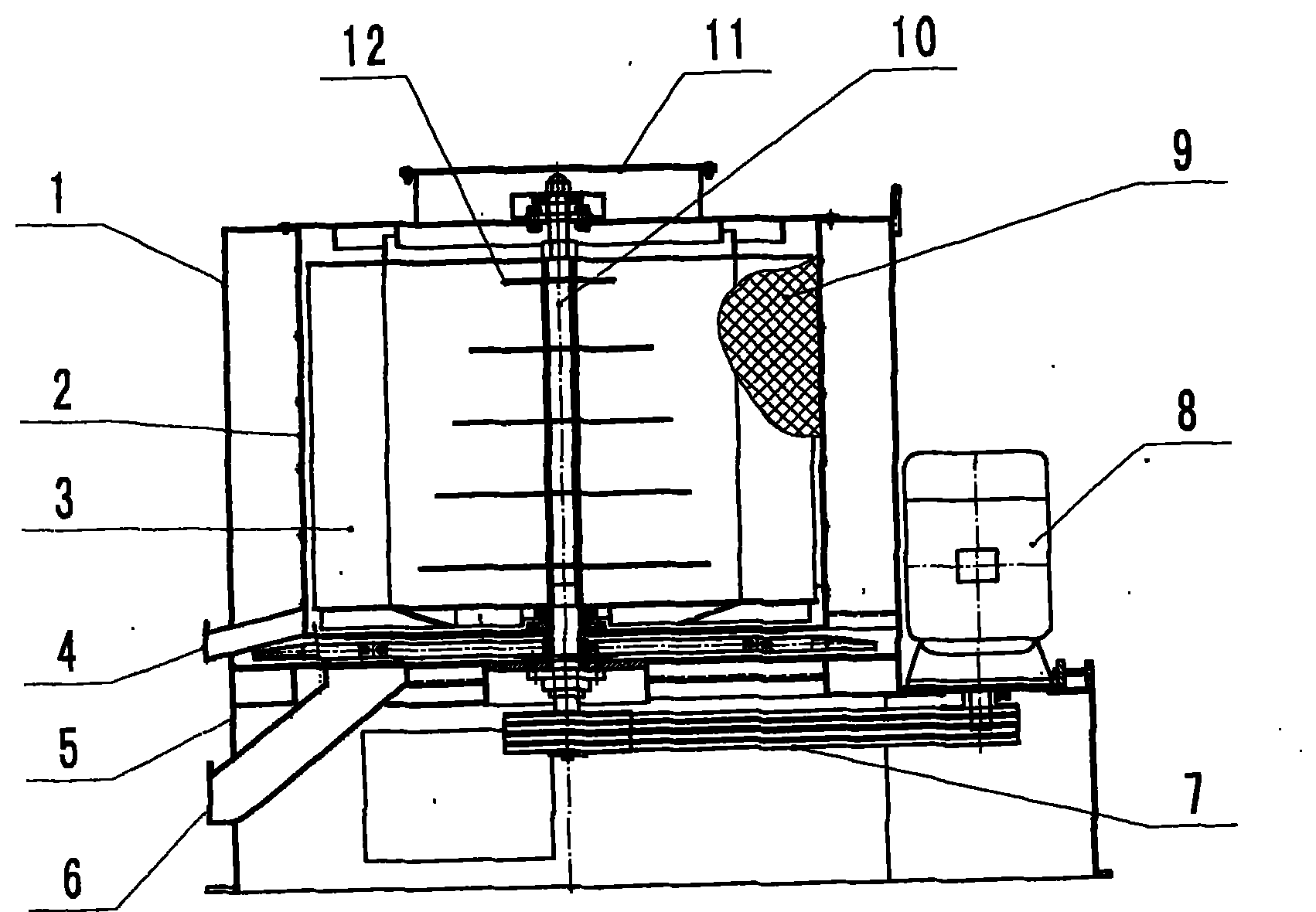

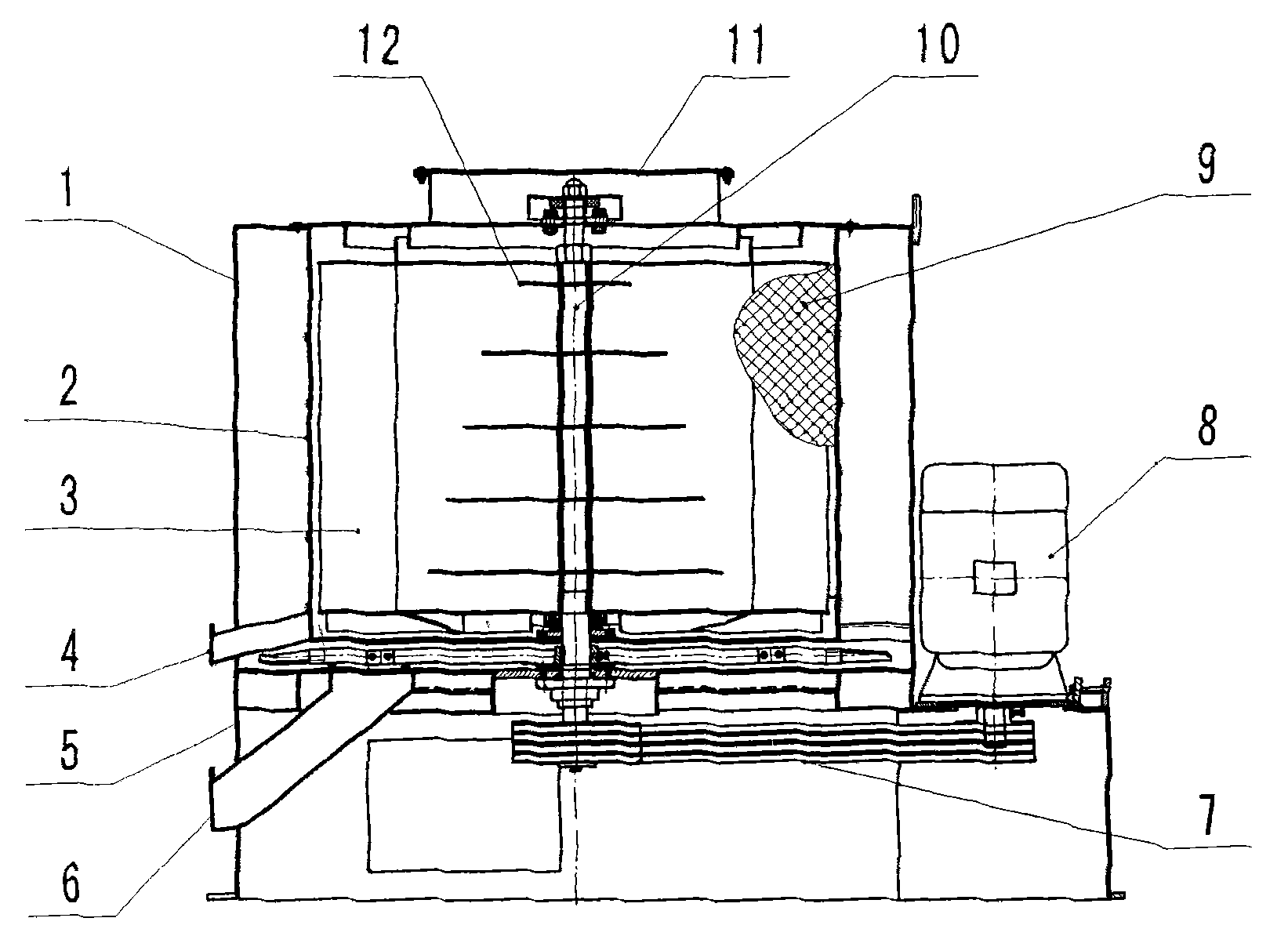

Centrifugal sieving machine

A sieving machine, centrifugal technology, applied in the direction of solid separation, separating solids from solids with air flow, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] Embodiments are described in detail with reference to the accompanying drawings. In the present invention, a central axis 10 is vertically installed in a cylindrical screen box 1 from the upper feeding port 11 to the lower machine base 5 and the upper two ends with bearing seats, and on the central axis in the screen box from top to bottom A multi-layer tower-shaped distributing tray 12 is installed, and fan blades 3 are symmetrically installed on the outer ring of the distributing tray in the screen box at the upper and lower ends of the central axis, and the upper and lower walls of the screen box outside the fan blades The upper grid frame 2 is equipped with a layer of filter screen 9, and the base at the bottom of the screen box is provided with a coarse material outlet 4 and a fine material outlet 6 that are connected to the inside and outside of the screen from the bottom, respectively. There is a driving motor 8, and a transmission mechanism 7 is connected betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com