Heavy-duty three-dimensional positioner

A three-coordinate locator and locator technology, applied in the locator field, can solve the problems of long manufacturing cycle, many assembly coordination links, no versatility, etc., and achieve the effects of improving stability, improving safety, and avoiding interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

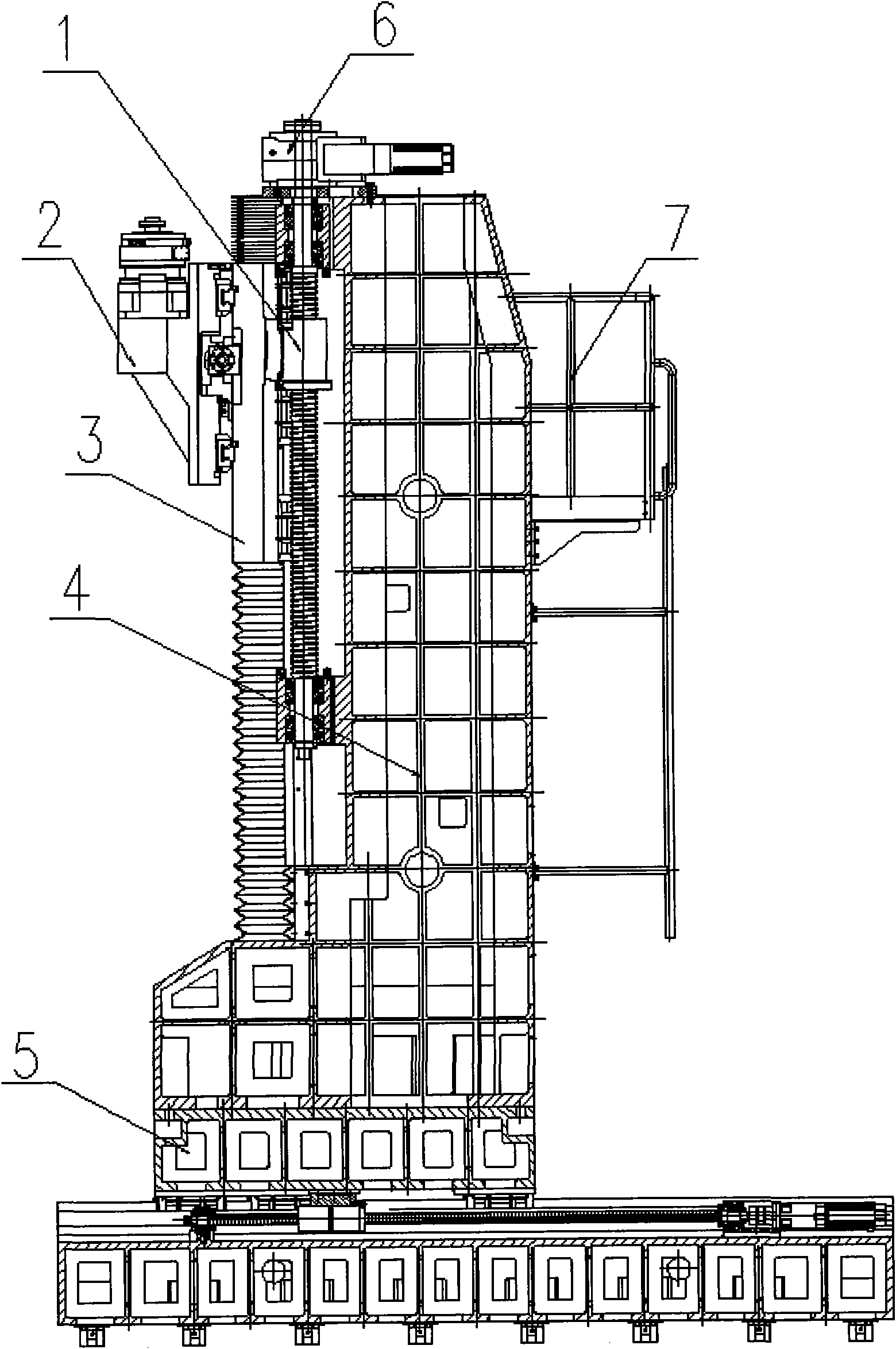

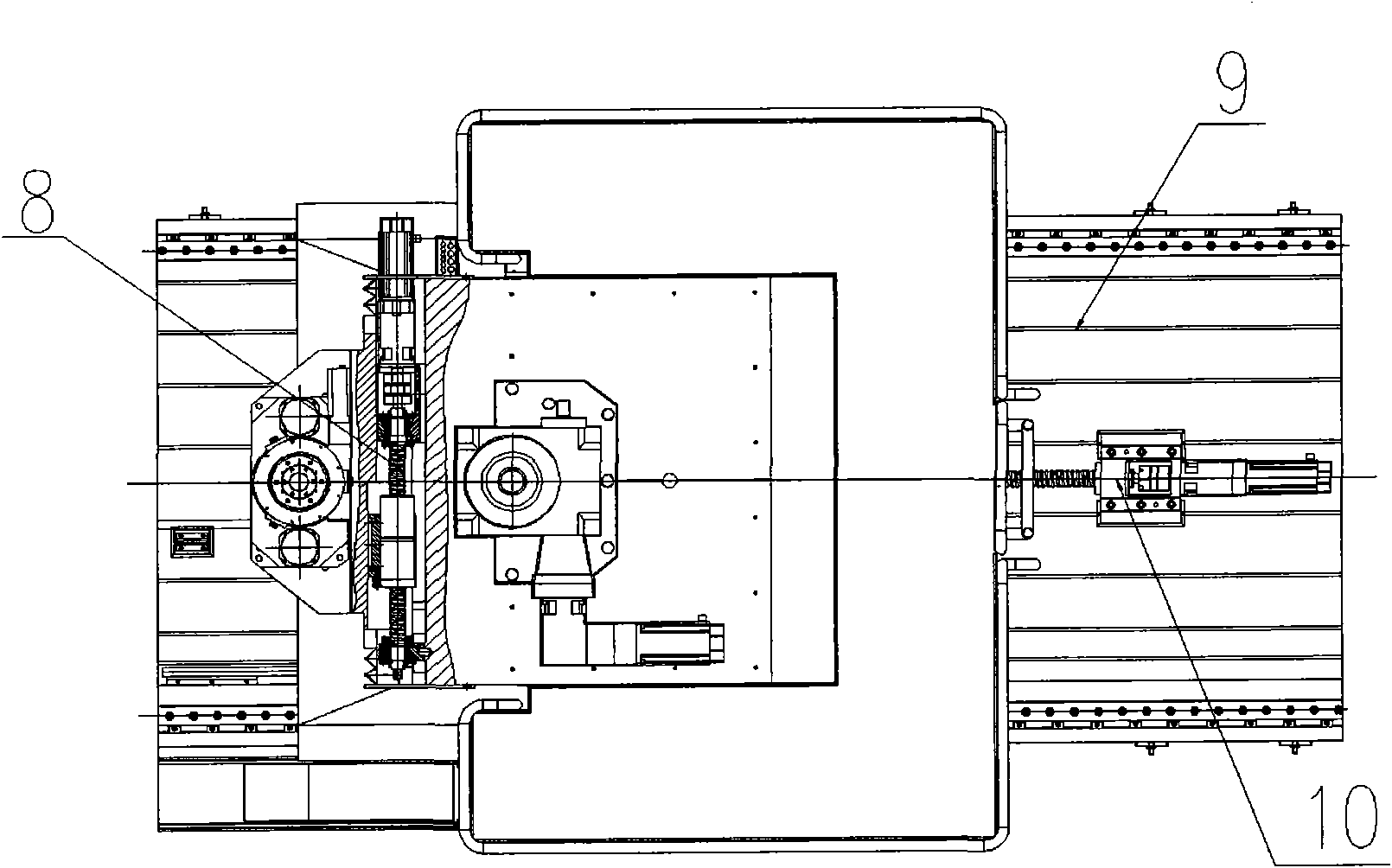

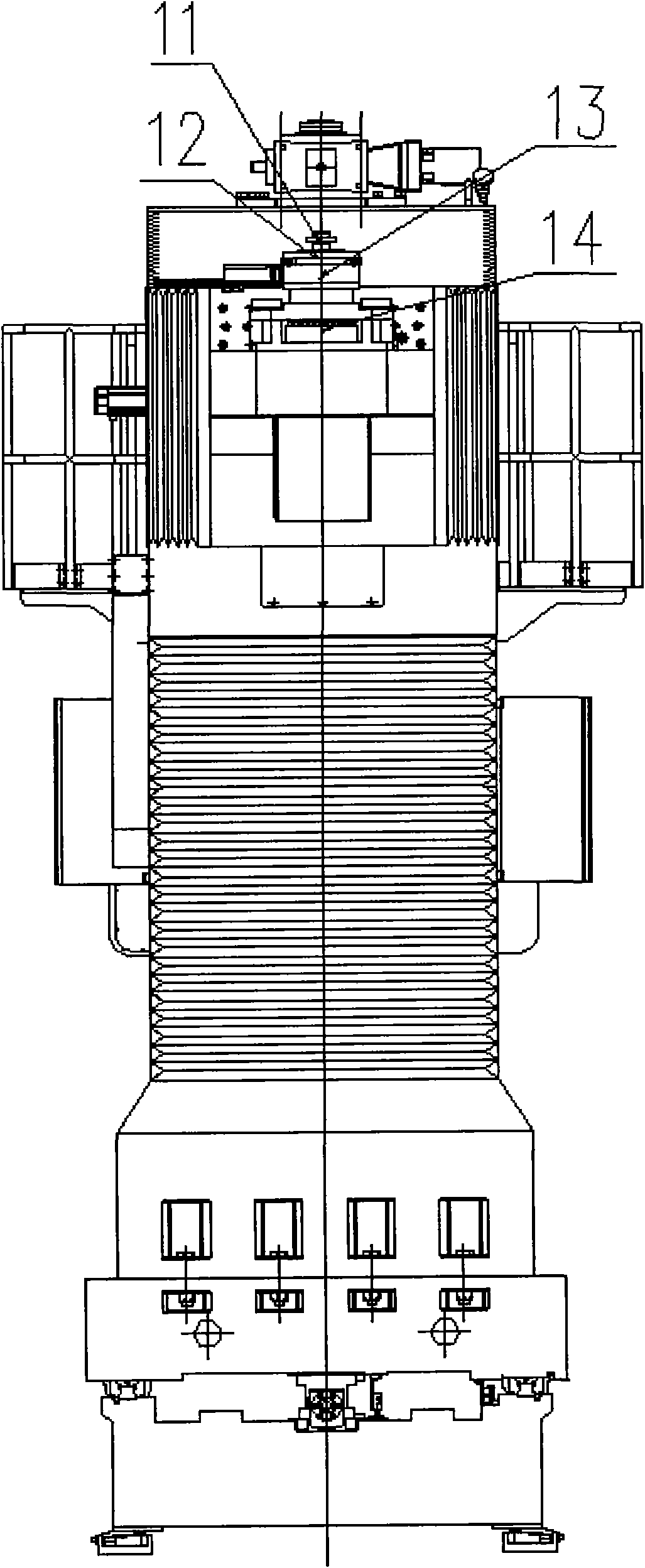

[0013] Such as Figure 1~3 As shown, the heavy-duty three-coordinate positioner includes a Z-direction transmission unit 1, an X-direction slide plate 2, a Z-direction slide plate 3, a column 4, a Y-direction carriage 5, a Z-direction worm gear reducer 6, an operating table 7, and an X-direction drive unit. Unit 8, base 9, Y-direction transmission unit 10, process ball head 11, ball head locking mechanism 12, ball head positioning mechanism 13, force measuring mechanism 14; base 9 is provided with Y-direction transmission unit 10, Y-direction transmission The unit 10 is equipped with a Y-direction carriage 5, and the Y-direction carriage 5 is provided with a column 4, and the side of the column 4 is provided with a Z-direction transmission unit 1, and the Z-direction transmission unit 1 is provided with a Z-direction slide 3, and the side of the Z slide 3 An X-direction transmission unit 8 is provided, and an X-direction slide plate 2 is provided on the X-direction transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com