Hydrogenation device and method for continuous hydrogenation on conjugated diene polymer by applying same

A conjugated diene and hydrogenation reaction technology is applied to a hydrogenation reaction device and the hydrogenation field where the device is applied, and can solve the problems of the failure of the hydrogenation catalyst, the temperature rise, and the reduction of the hydrogenation rate of the conjugated diene polymer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

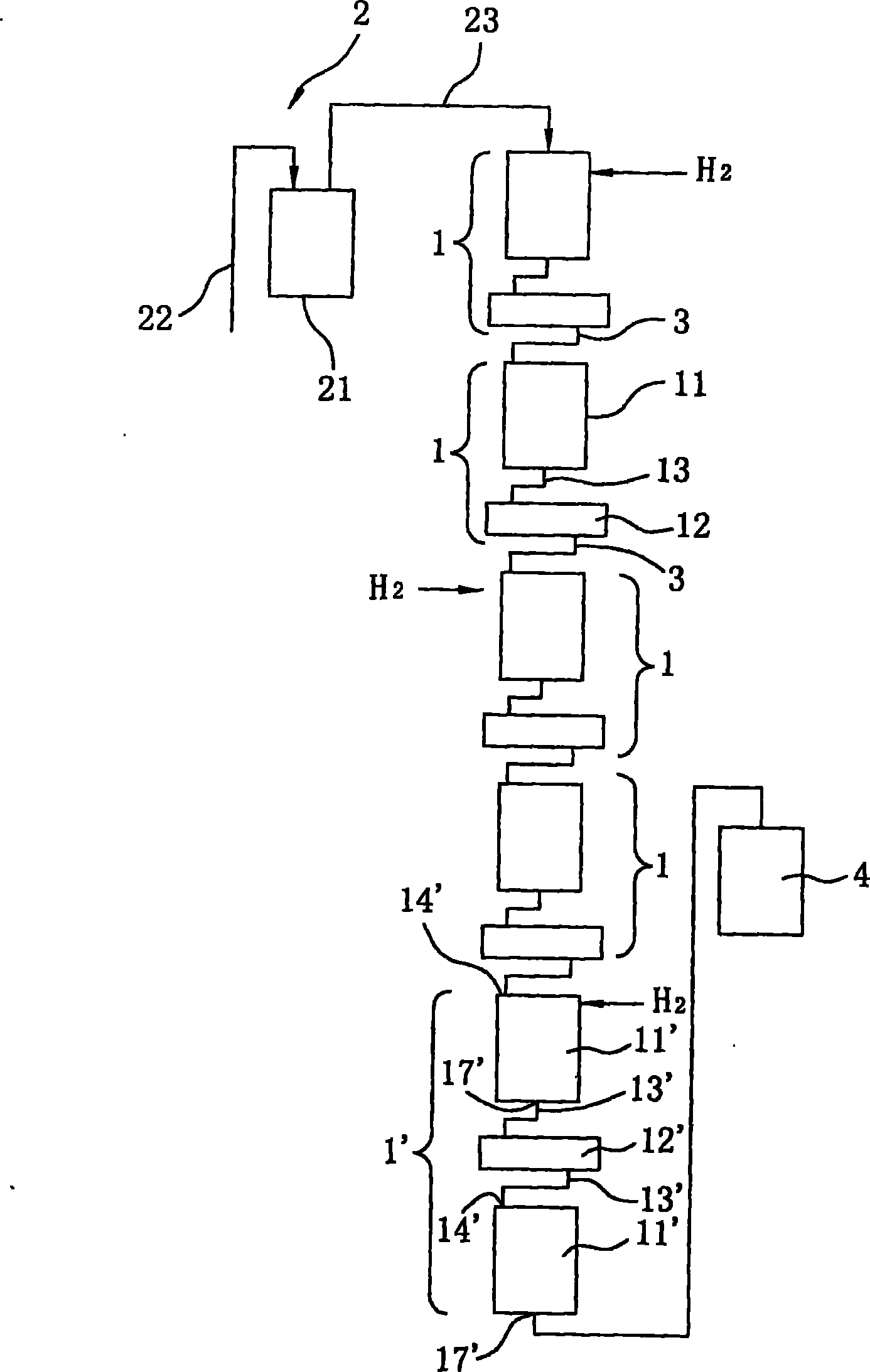

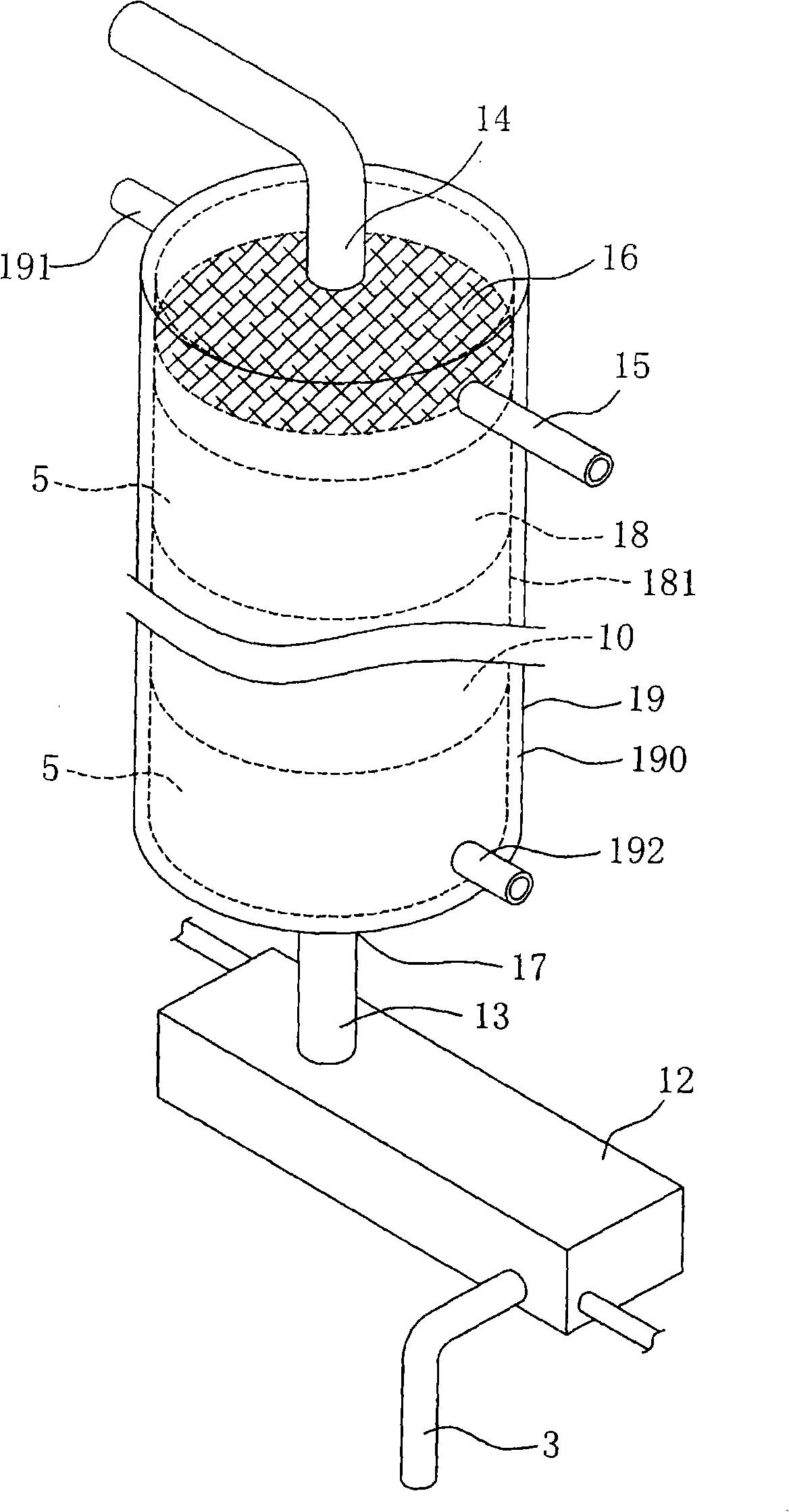

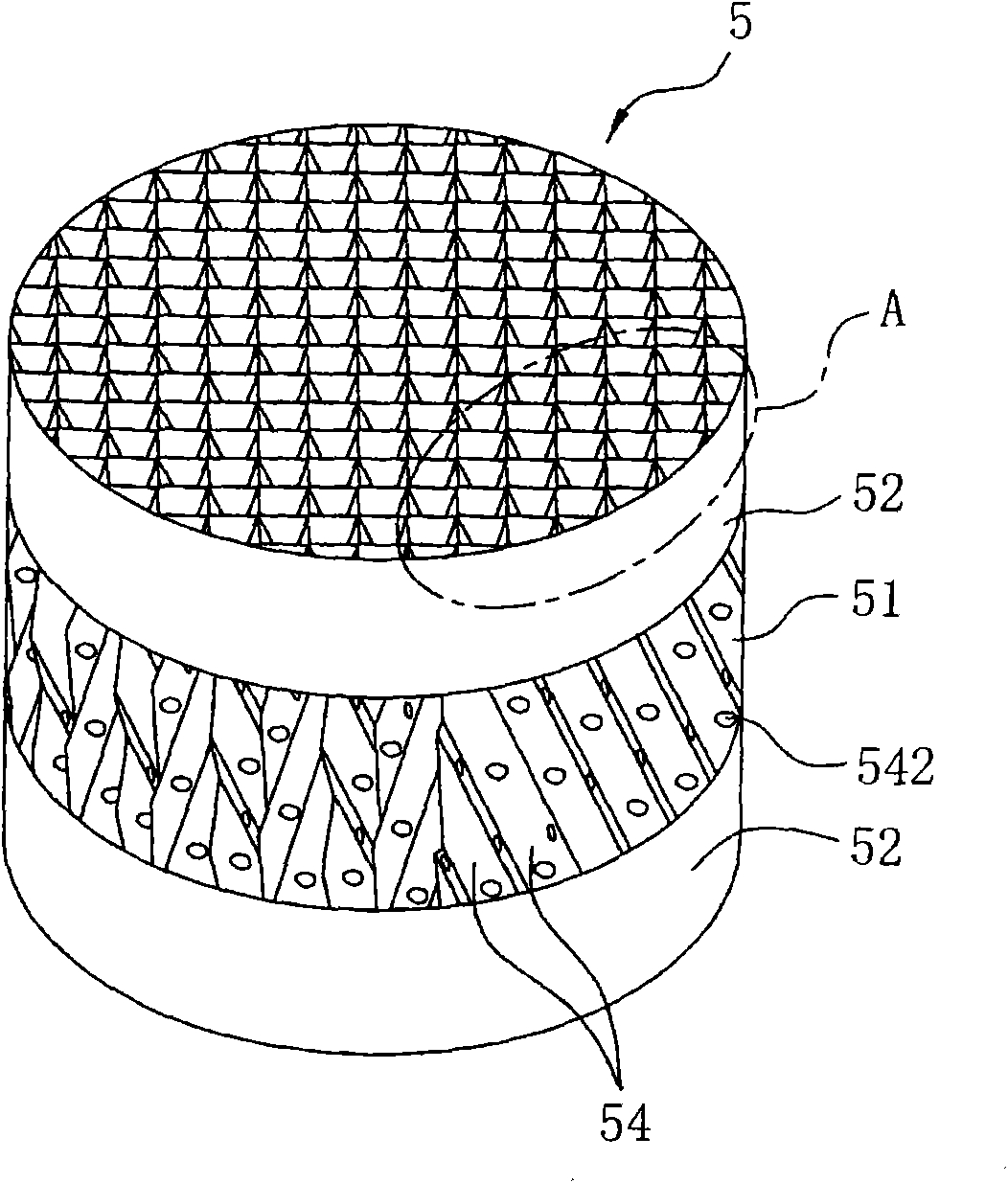

[0096] Example 1: Continuous Hydrogenation of Conjugated Diene-Based Polymers

[0097] The conjugated diene polymer SBS-1 is 0.246g / hr (0.71 millimole / hr), 1.05g / hr, 0.57g / hr feed amount, and cooperate solvent cyclohexane to import such as figure 1 Form a reaction mortar (solid content 15% by weight) after stirring and mixing in the shown mixing tank 21; Above-mentioned reaction mortar is imported such as figure 1 In the hydrogenation reaction device, and each hydrogenation reactor of the hydrogenation reaction device is built in such as image 3 several packing pieces, and simultaneously introduce hydrogen into the hydrogenation reactors numbered A, C, E (as described later), so that the hydrogen inlet pressure in each hydrogenation reactor is maintained at 9kg / cm 2 g, and by controlling the interlayer water temperature and heat exchangers 12, 12' of each hydrogenation reactor 11, 11' (numbered A, B, C, D, E and F from upflow to downflow) to remove Heat, so that the averag...

Embodiment 2~4

[0099] Embodiments 2 to 4 carry out the hydrogenation reaction with the same hydrogenation reaction device and steps as in Embodiment 1. The difference is that the embodiments 2 to 4 use the conjugated diene polymer SBS- 1 or conjugated diene polymer SBS-2, and dicyclopentadienyl titanium dichloride, polymethylhydrogensiloxane and n-butyl lithium in different feed amounts, and different hydrogenation conditions to obtain hydrogenated Table 1 also lists the conjugated diene polymer and the hydrogenation rate of the hydrogenated conjugated diene polymer obtained therefrom.

[0100]From the results of the above examples, it is known that when the continuous hydrogenation reactor of the present invention is used to hydrogenate a conjugated diene polymer, the filler 5 in the hydrogenation reactor 11, 11' can slow down the downward flow of the polymer. The rate and then prolong the reaction time, so that the hydrogenation reaction of the polymer with hydrogen and the hydrogenation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com