Method for producing vitamin C by elec-trodialysis with bipolar membrane

A bipolar membrane electrodialysis and bipolar membrane technology, applied in organic chemistry, fermentation, etc., can solve problems such as underutilization of sodium hydroxide, scaling and deposition of high-valent metal ions, and affecting the operating life of the membrane system. Scaling tendency, reducing acid and alkali consumption, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

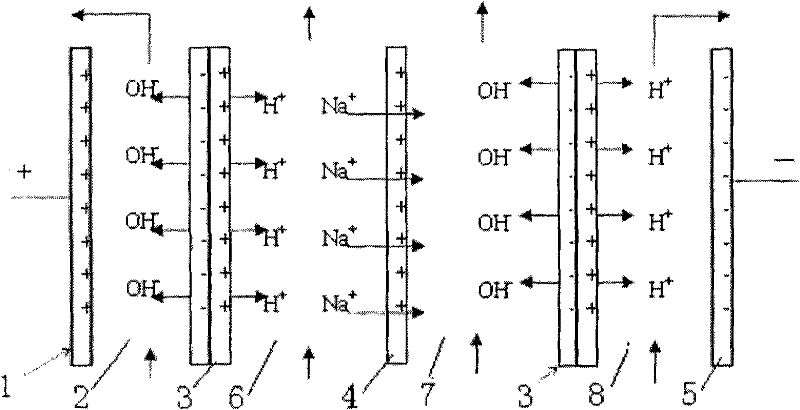

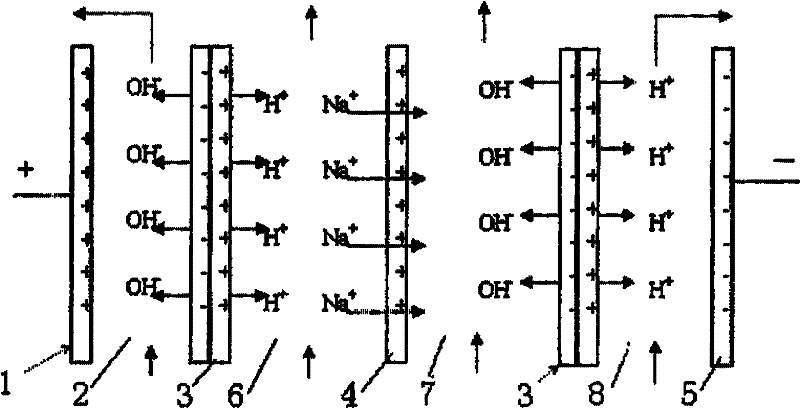

[0036] A set of bipolar membrane electrodialysis device is included in this embodiment. The bipolar membrane electrodialysis device is composed of two bipolar membranes, a cationic membrane and a pair of electrodes. Pole membrane, cationic membrane, bipolar membrane and cathode plate. This structure determines the four working areas of the bipolar membrane electrodialysis device: anode chamber, transformation chamber, hydrolysis chamber and cathode chamber. The area formed between the anode plate and the adjacent bipolar film is the anode chamber, the cathode side of the bipolar film is opposite to the anode plate; the area formed between the cathode plate and the adjacent bipolar film is the cathode chamber, the The anode side of the bipolar membrane is opposite to the cathode plate; between adjacent bipolar membranes is a cationic membrane, between the cationic membrane and the bipolar membrane on the anode side is the conversion chamber, and between the cationic membrane an...

Embodiment 2

[0049] The bipolar membrane electrodialysis device applied in the present embodiment is identical with embodiment 1, but when being applied to the production of vitamin C, carry out according to the following steps:

[0050] 1) Fermentation produces sodium guronate,

[0051] 2) using a cation exchange resin to convert sodium guronate into guronic acid,

[0052] 3) Guronic acid reacts with methanol under acidic conditions to generate guronic acid methyl ester,

[0053] 4) make the bipolar membrane electrodialysis device according to the above method,

[0054] 5) 4% NaOH solution is pumped into the anode chamber and the cathode chamber according to a certain flow rate for circulation; the methyl guronate to be hydrolyzed is pumped into the hydrolysis chamber for circulation at a certain flow rate; the vitamin C sodium solution is pumped into the conversion chamber to cycle;

[0055] 6) Apply a DC power supply between the two electrode plates after the cycle is stable;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com