Construction method of cross-valley overhead pipeline

A technology for overhead pipelines and construction methods, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve problems such as difficult conditions, hidden safety hazards, and high costs, and achieve construction cost saving, saving expenses, The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

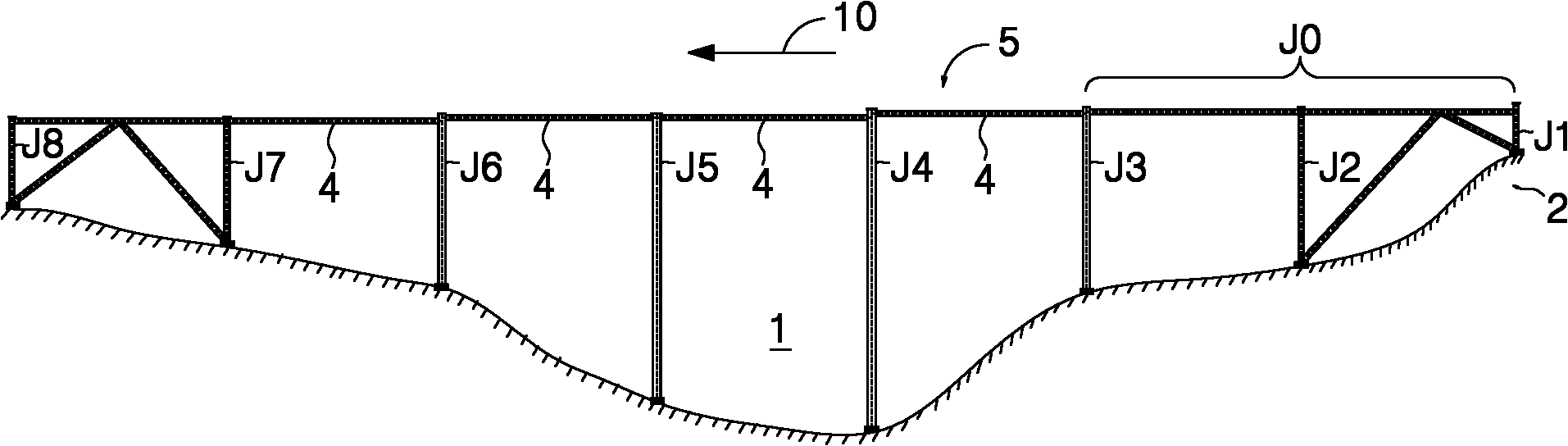

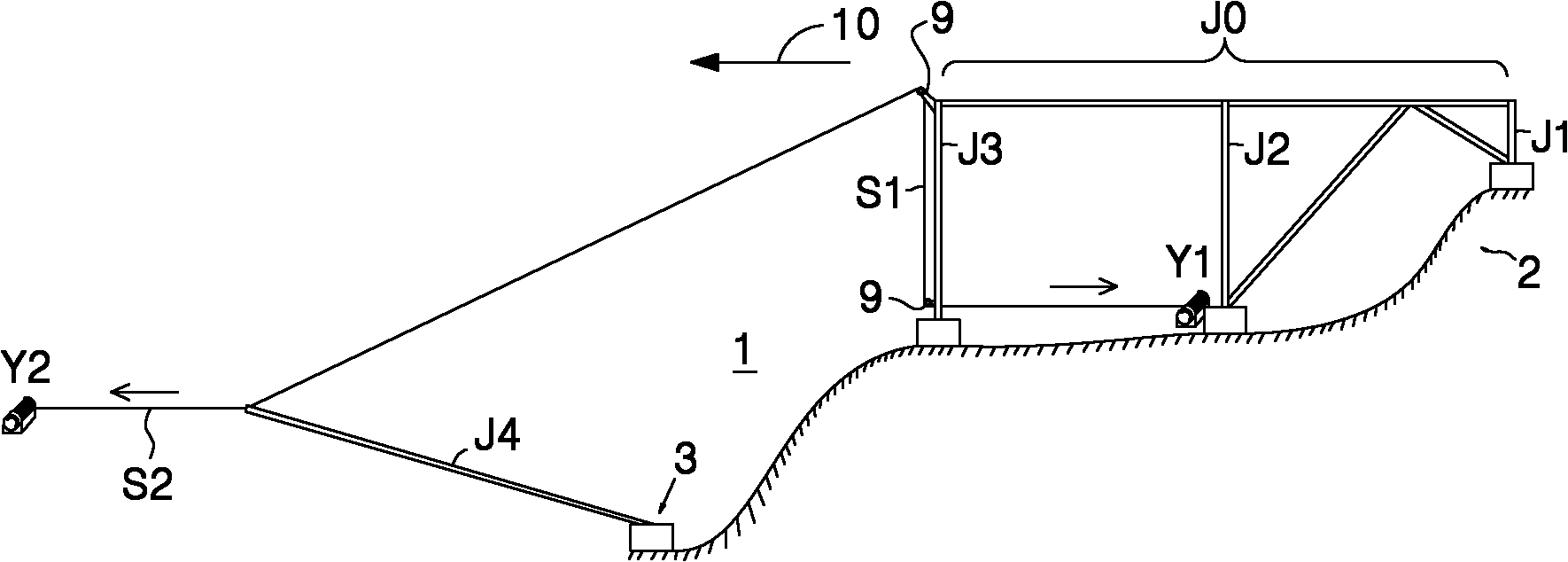

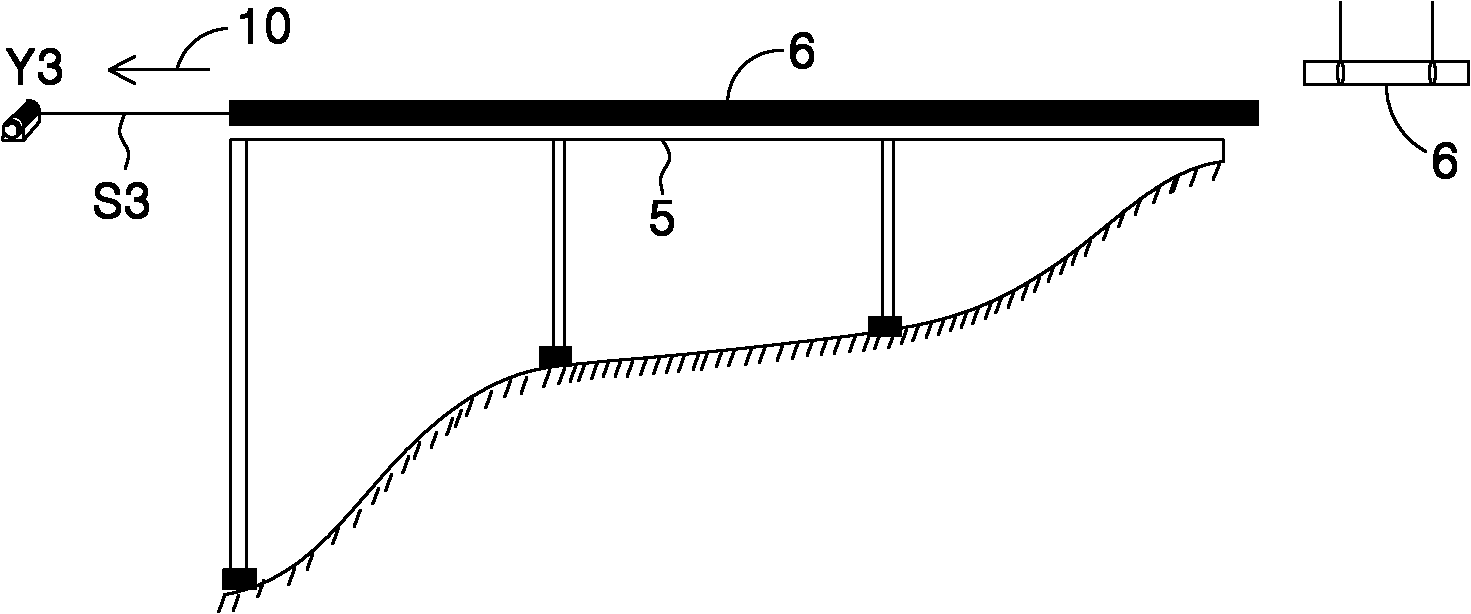

[0021] Such as Figure 1~3 Shown, cross-valley overhead pipeline construction method of the present invention comprises the following steps:

[0022] 1) Set up the pipeline support J0 at the beginning 2 of the valley 1;

[0023] 2) Install the pulley device 9 on the established pipeline support J0, use the lifting hoist Y1 to guide the pulley device 9 to lift the previous pipeline support J4, and fix the support base 3 after it is in place;

[0024] 3) Connecting members 4 are arranged between the pipeline supports to form a working bridge 5;

[0025] 4) Use the traction hoist Y3 to implement the horizontal traction of the pipeline 6 on the working bridge 5 .

[0026] Such as figure 1 , the "starting point 2" in step 1) refers to the position where the ramp on the side of the valley 1 starts. The selection of the starting point 2 of the valley 1 is preferably base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com