Method for automatically assembling and producing fireworks

A technology of automatic charge machine and fireworks, which is applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of poor safety conditions and low labor efficiency, and achieve the effects of reducing product costs, high production efficiency, convenience and labor-saving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

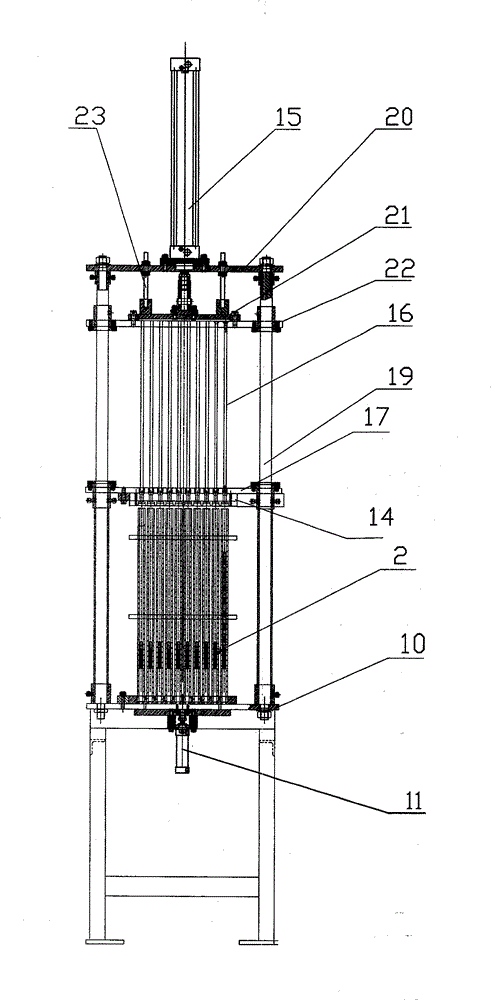

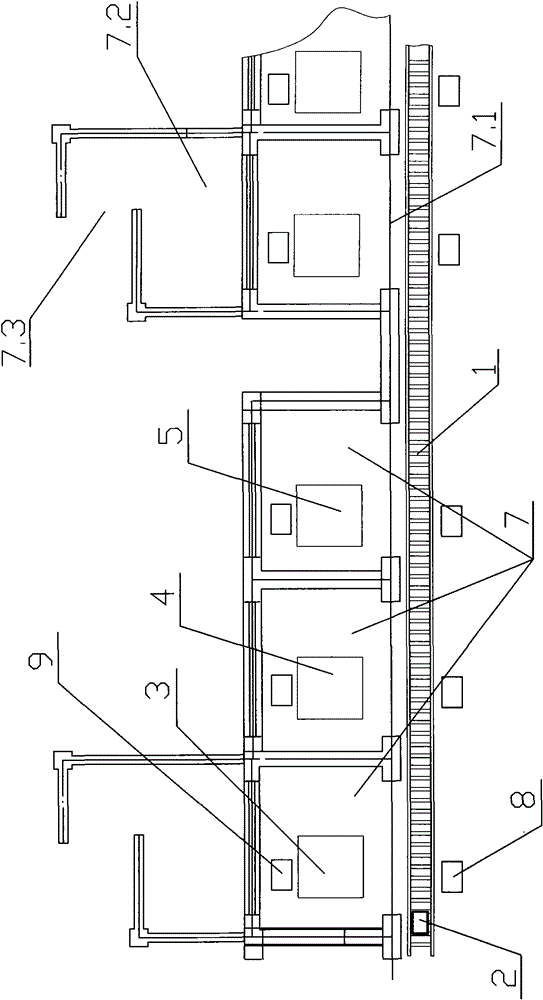

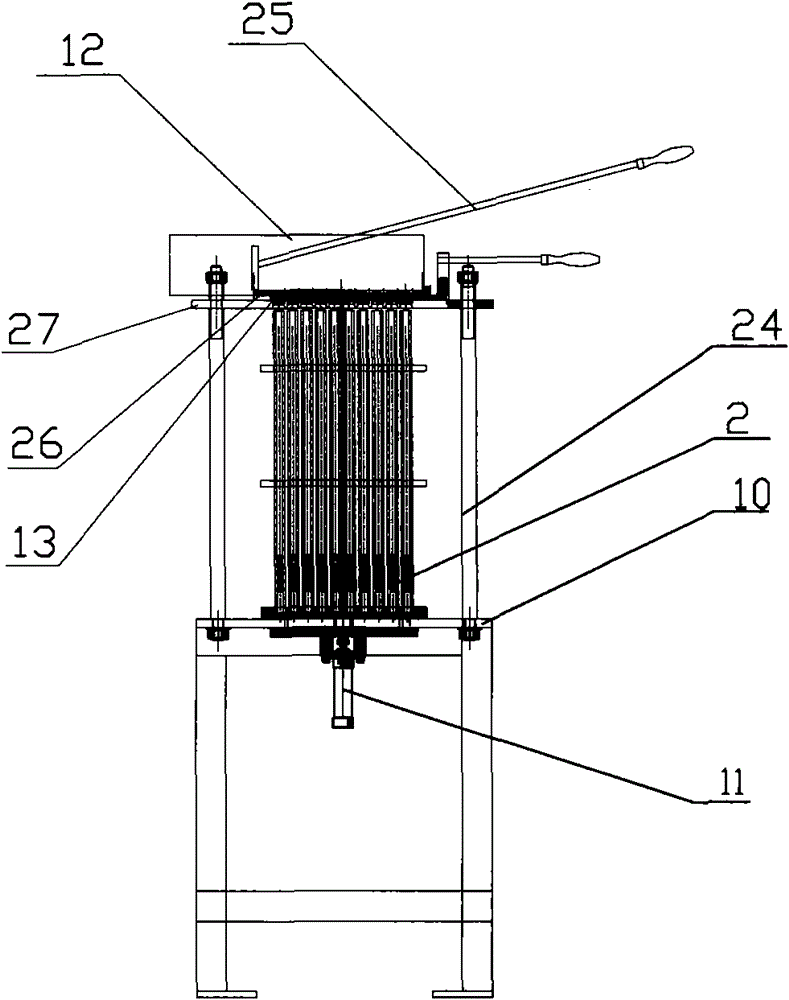

[0037] Such as figure 1 , 2 , shown in 3, 4, 5, 6: a kind of automatic assembly method of the present invention produces fireworks, is to adopt conveyer belt (1) that pipe body formwork (2) is transported to automatic charge machine (3) charge, pack The pipe body formwork (2) after medicine is transported to the automatic bead loading machine (4) by the conveyor belt (1) for loading beads, and the pipe body formwork (2) after the bead loading is transported to the automatic soil loading machine ( 5) load the soil, complete the process of loading guns for one sound; the pipe body (6) in the pipe body formwork is at least one sound above, and the pipe body formwork ( 2) Transport to the packaging room through the conveyor belt (1) and the packaging process is completed;

[0038] The production process steps of the first cannon with 100 eight-ring flash mines are as follows:

[0039] (1), 100 pipe bodies (6) are loaded onto the pipe body formwork (2), and the main leads are pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com