White light interferometer with fast zero-setting system

A white light interferometer and zero-adjustment technology, which is applied in the field of white light interferometers, can solve problems such as longitudinal measurement resolution gaps, and achieve the effects of reducing adjustment time and improving detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

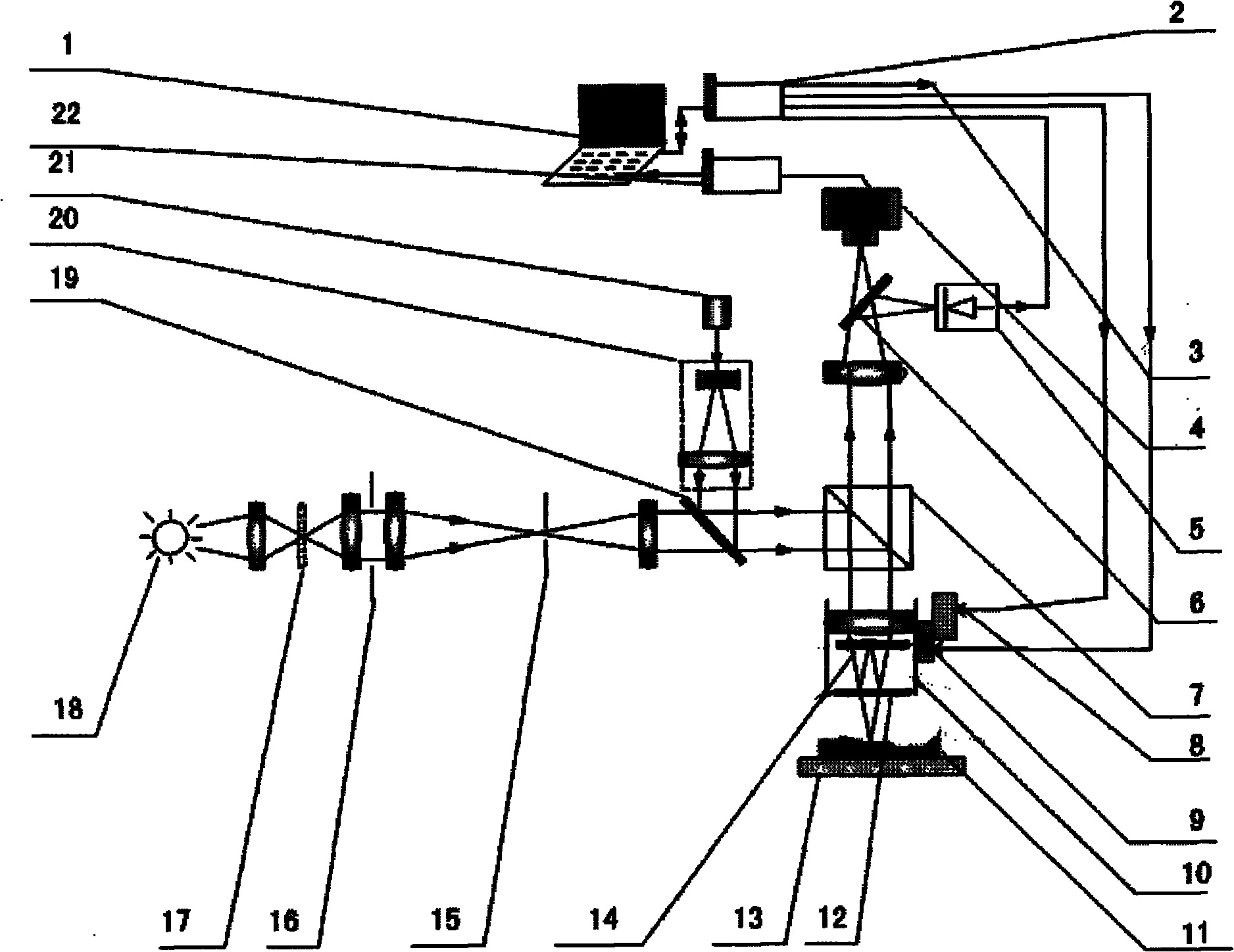

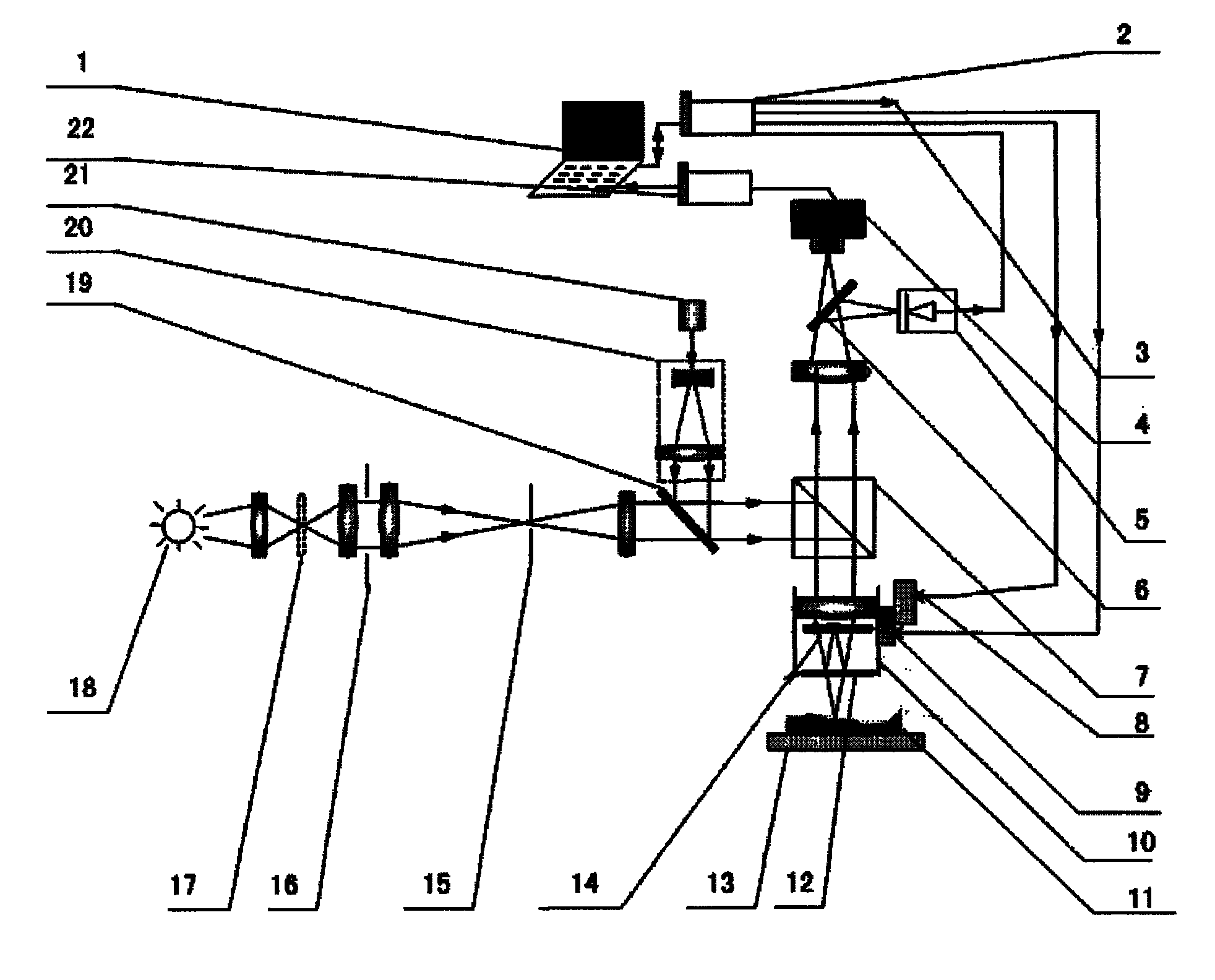

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

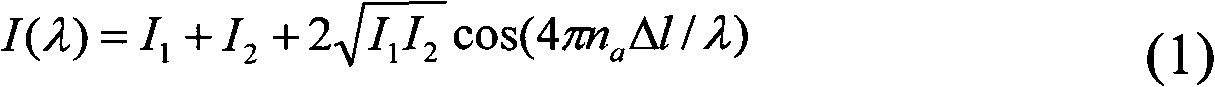

[0016] As shown in the accompanying drawing, the white light of the white light source is collimated by the removable narrow-band filter 17, the aperture stop 16, the field stop 15 and the collimation system, and is reflected by the first beam splitter 7 into the microscope. The objective lens 10 is divided into two beams by the second beam splitter 12, one beam hits the reference mirror 14, and the other beam hits the measured surface 11, after the two beams interfere on the second beam splitter 12, they converge The lens enters the CCD camera 4, and is connected to the computer 1 through the image acquisition card 22; the piezoelectric ceramic 9 and the precision translation stage 8 installed on the microscope objective lens are respectively connected to the computer 1 through the AD / DA card 2. The laser light emitted by the tunable laser 21 is expanded by the beam ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com