Universal straw cutter matched with combine harvester

A technology for combine harvesters and straw shredders, applied in the fields of agricultural machinery and straw shredders, which can solve the problems of low installation rate, troublesome maintenance of transmission system, blockage of shredders, etc., achieve less and convenient maintenance, and save comprehensive agricultural costs , the effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

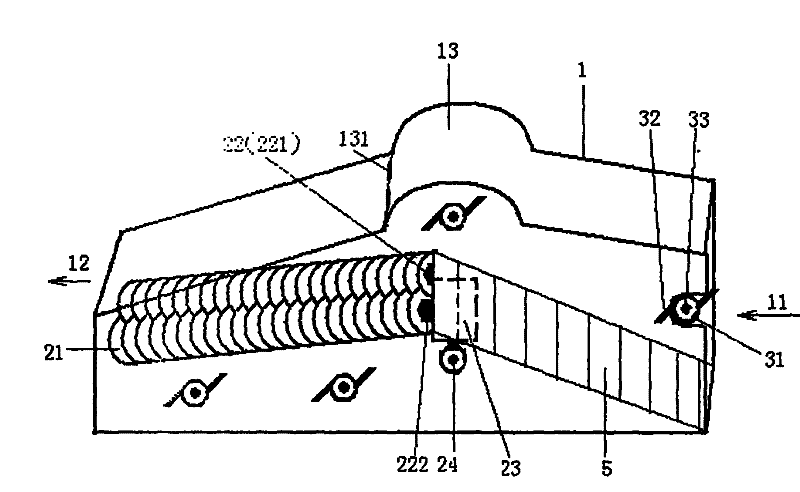

[0023] Such as figure 1 as shown,

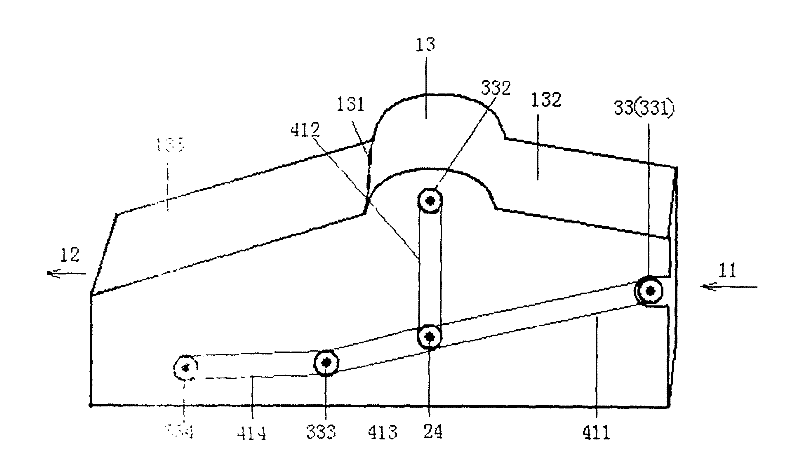

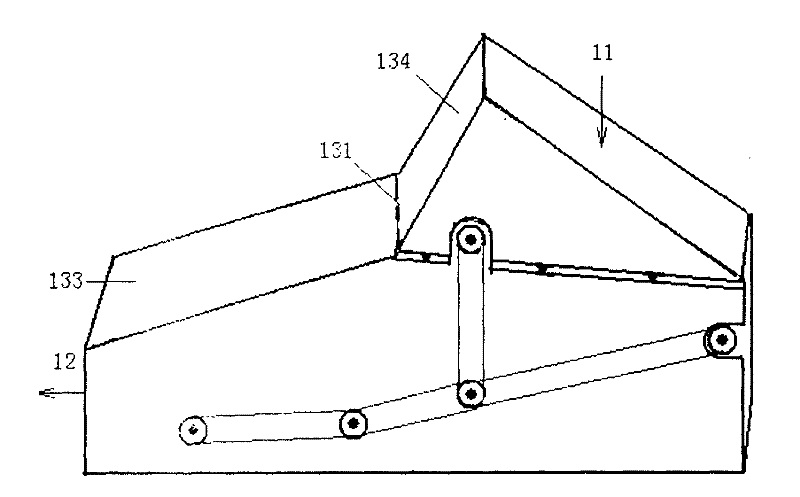

[0024] The present invention is matched with a combine harvester, and is mainly composed of a housing 1, a cutter device arranged in the housing, a grass discharge device and a transmission device. Described cutter device mainly is made up of cutter disc 21, cutter rotating shaft 22 and its speed-changing device 23; Described grass discharge device is mainly made up of grass discharge wheel 31, grass guide plate 32; Described transmission device Mainly be made up of the wheel axle 33 of discharging grass, cutter rotating shaft drive main shaft 24, and the transmission belt that connects each axle, rotating shaft. The shaft end of the A rotating shaft 221 of the regular hexagonal cylindric cutter rotating shaft of the described cutter device is connected with the bevel gear (not shown) in the speed change and direction change device set by the drive main shaft; The output shaft (not shown in the figure) of the worm gear reducer in the devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com