Vibrating screen

A vibrating screen and vibrating arm technology, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of large foundation vibration force, large screen box structure, screen vibration, etc., and achieve small vibration quality and adjustable parameters Multiple, uniform vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

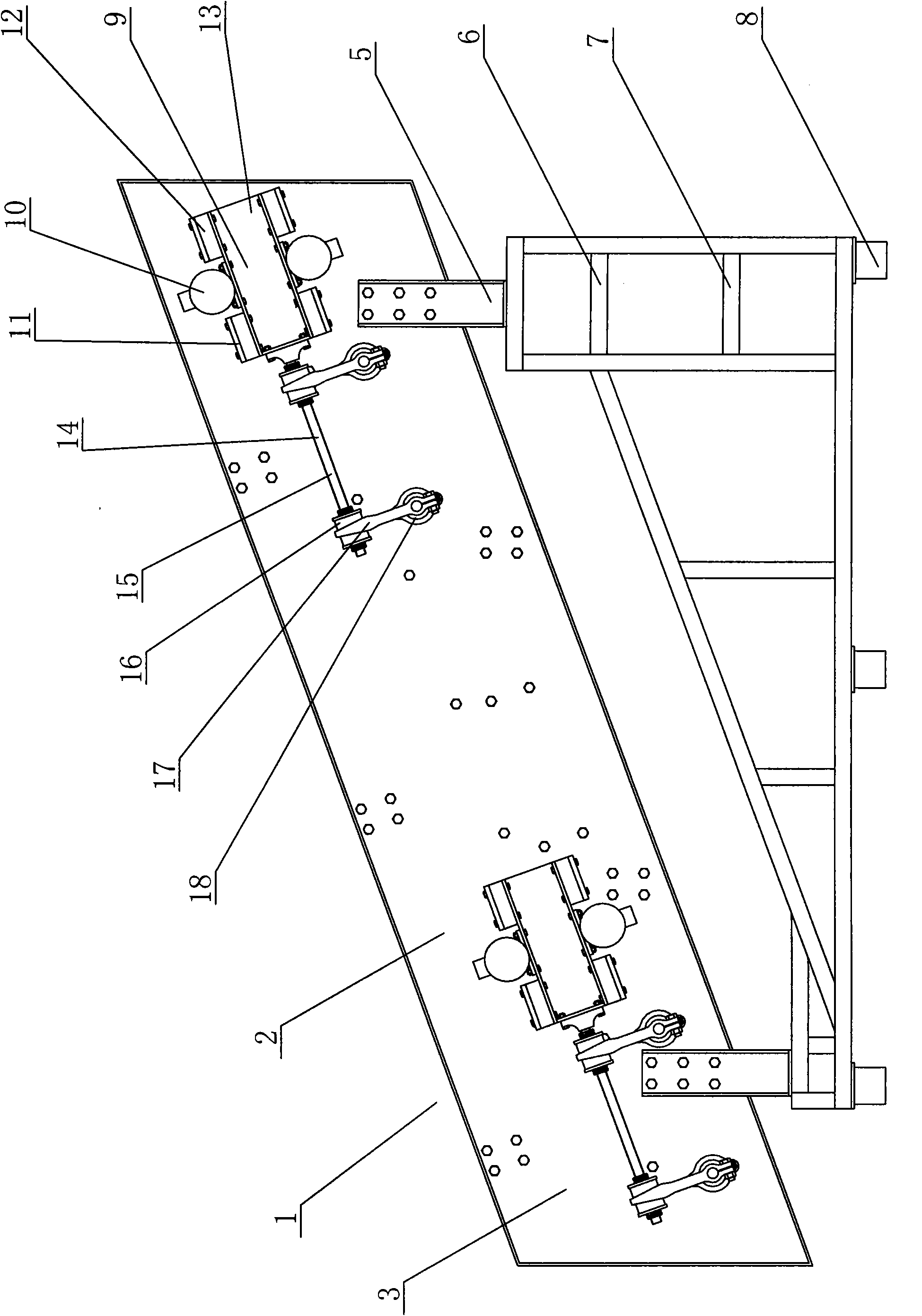

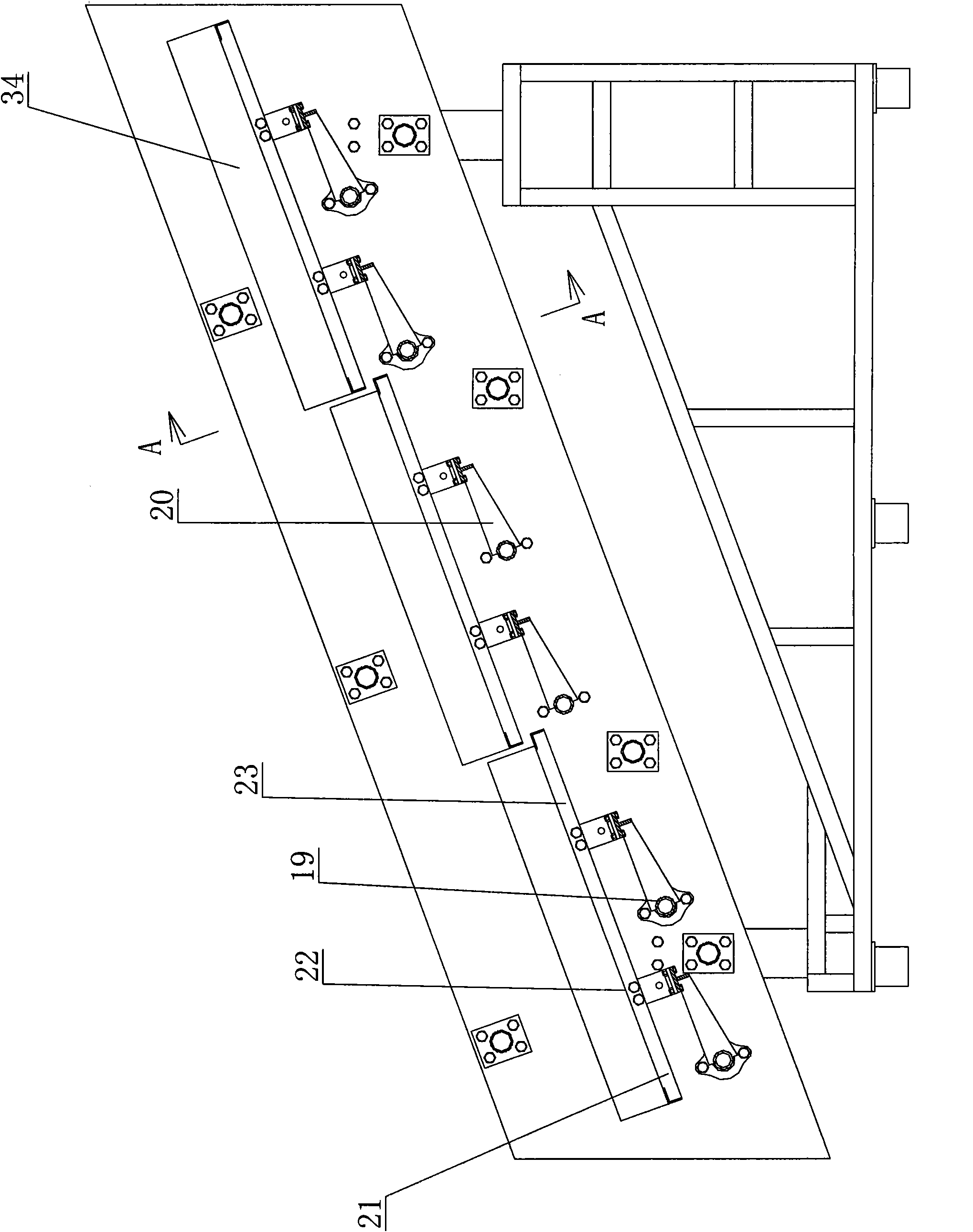

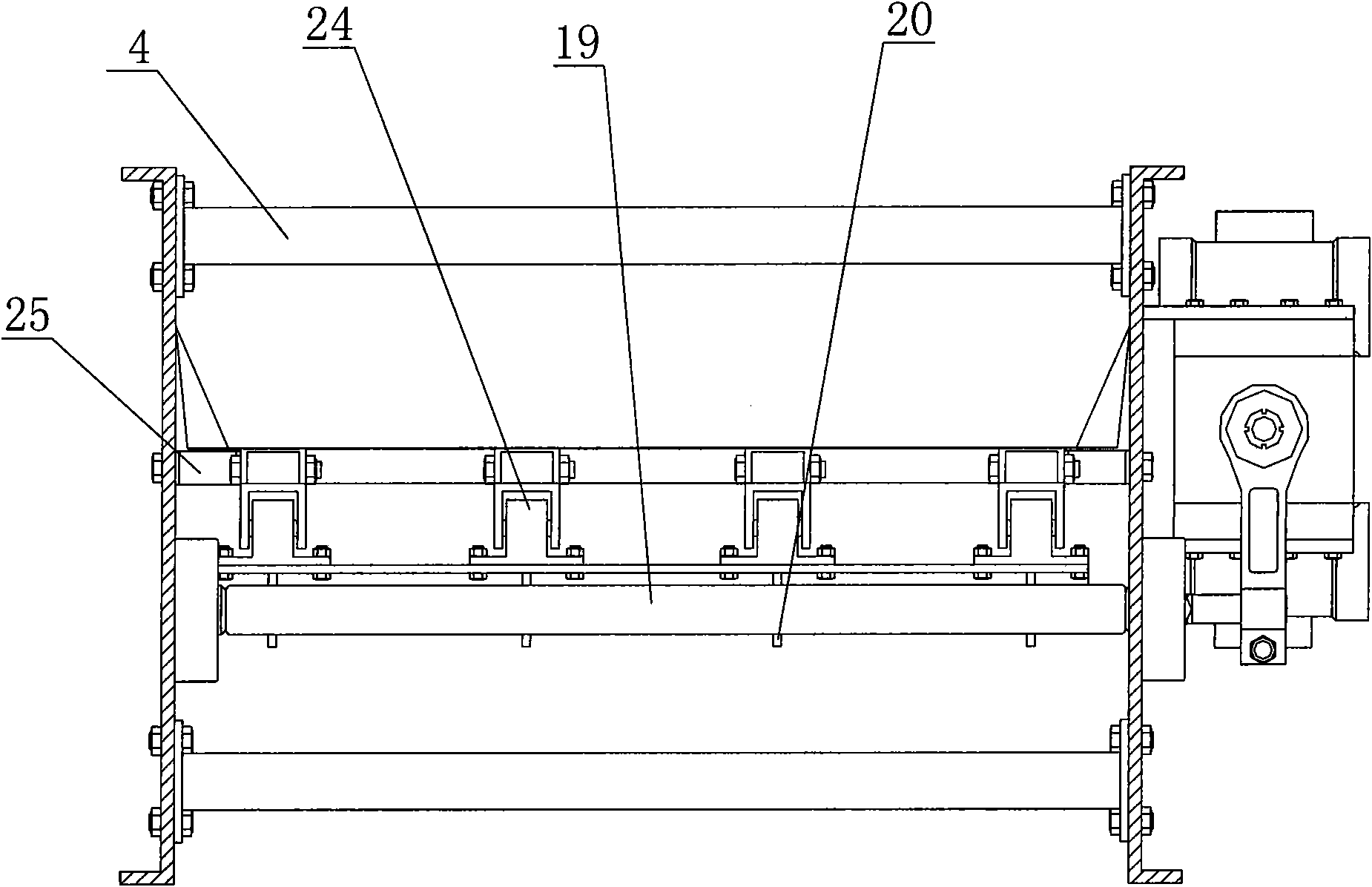

[0018] Example 1, in Figure 1 to Figure 6 Among them, a vibrating screen 1 is provided, the screen box 2 is composed of a side plate 3, a beam 4 and a support foot 5, the beam 4 is installed between two side plates 3 to improve the strength of the screen box, and the frame 6 includes a channel steel frame 7 and spring base 8, the screen box 2 is installed on the channel steel frame 7, and the spring base 8 is directly placed on the foundation to reduce the vibration to the foundation. Composed of motor beam 13, support plate 11 is directly welded on the outside of side plate 3, vibration motor 10 is installed on motor beam 13, motor beam 13 is installed on support plate 11 through rubber spring 12, vibrator 9 is respectively arranged on two sides On the outside of block side plate 3, transmission mechanism 14 is made up of transmission rod 15, connector 16, vibration rod 17, rotating shaft seat 18, rotation shaft 19 and vibration arm 20, and one end of transmission rod 15 is ...

Embodiment 2

[0020] Example 2, in Figure 1 to Figure 5 and Figure 7 Among them, a vibrating screen 1 is provided, the screen box 2 is composed of a side plate 3, a beam 4 and a support foot 5, the beam 4 is installed between two side plates 3 to improve the strength of the screen box, and the frame 6 includes a channel steel frame 7 and spring base 8, the screen box 2 is installed on the channel steel frame 7, and the spring base 8 is directly placed on the foundation to reduce the vibration to the foundation. Composed of motor beam 13, support plate 11 is directly welded on the outside of side plate 3, vibration motor 10 is installed on motor beam 13, motor beam 13 is installed on support plate 11 through rubber spring 12, vibrator 9 is respectively arranged on On the outside of the two side plates 3, the transmission mechanism 14 is composed of a transmission rod 15, a connector 16, a vibrating rod 17, a rotating shaft seat 18, a rotating shaft 19 and a vibrating arm 20, and one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com