Thin-film bonding machine table, thin-film bonding method and manufacturing method of solidifying film layer

A manufacturing method and a technology of an attaching machine, which are applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of affecting structural integrity, changing the alignment of liquid liquid crystal materials, and decreasing the yield of lenticular lens panels. Improve the effect of attaching yield, uniform force and uniform total thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

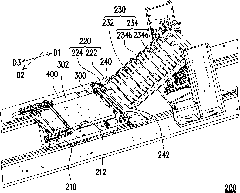

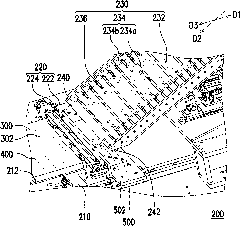

[0072] figure 2 It is a schematic diagram of a film attaching machine according to an embodiment of the present invention, image 3 for figure 2 The partial enlarged view of Figure 4 for figure 2 side view. Please also refer to figure 2 , image 3 and Figure 4 , the film attaching machine 200 includes a first carrier 210 , a clamping device 220 , a second carrier 230 and a pressing element 240 . The first carrying platform 210 has a first carrying surface 212 for carrying a plate 300 . The clamping device 220 is arranged on one side of the first carrying platform 210, and the second carrying platform 230 is located above the clamping device 220. The second carrying platform 230 has a second carrying surface 232 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com