Automobile fuel filler cap assembly

A fuel cap and assembly technology, which is applied to vehicle components, the arrangement combined with the fuel supply of the internal combustion engine, and the power unit, etc., can solve the problem that the appearance gap between the fuel cap and the surrounding overlapping parts is difficult to guarantee, and it is difficult to ensure the consistency and movement accuracy. The product quality is difficult to guarantee and other problems, to achieve the effect of compact structure, light weight and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

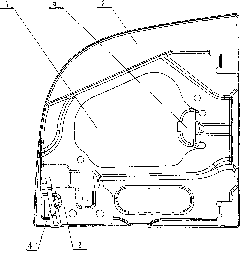

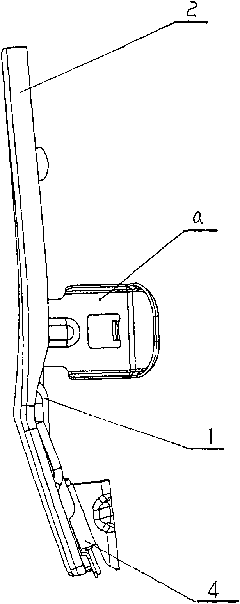

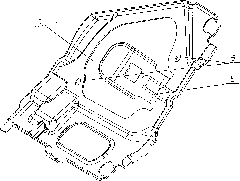

[0015] see figure 1 , figure 2 with image 3 The fuel cap assembly of an automobile shown includes a reinforcing member 1 connected to the fuel cap body 2, and the hinge assembly connected to the reinforcing member is formed by rolling and pressing a female hinge 3 and a hinge pin 4 through a mold;

[0016] There is a buckle a on the reinforcement 1, which is integrated with the reinforcement, and a round rib 5 is provided at the root of the buckle; a positioning hole 6 is provided on the reinforcement 1, and its function is to unify the positioning reference , to ensure the positional accuracy of the lock buckle, and to avoid the error effect caused by multiple positioning; the reinforcing rib b and the sinking platform c are also provided on the reinforcing member 1 to improve the structural strength of the fuel cap assembly.

[0017] The automobile fuel cap asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com