Compound groove tank for tanker

A composite tank and tanker technology, applied in the field of trucks, can solve problems such as oil or chemical leakage, metal tank rupture, environmental problems, etc., and achieve the effects of reducing transportation costs, low fuel consumption, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below through specific examples, so as to help to understand the content of the present invention.

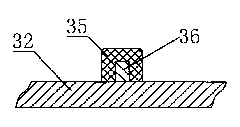

[0037] Such as figure 2 As shown, it is an embodiment of a tank car composite tank. The tank body of the inner layer includes a stainless steel cylinder body 32 and a stainless steel head 34. The pouring polyurethane elastomer rib net 35 formed by the cast polyurethane elastomer strips in the direction, utilizes the high strength of the cast polyurethane elastomer rib net 35 to ensure that the strength of the entire tank meets the strength requirements of the tank truck tank, thereby being compatible with the existing Compared with traditional stainless steel tanks, the wall thickness of stainless steel tanks is reduced, thereby reducing the amount of stainless steel and reducing the weight of the tank.

[0038] The cast polyurethane elastomer mesh can directly cover and wrap the outer surface of the stainless s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com