Continuous photocatalytic reaction device

A photocatalytic reaction and reaction zone technology, which is applied in the direction of light water/sewage treatment, etc., can solve the problems of undiscovered reaction devices, etc., and achieve the effects of high utilization rate, convenient sampling and testing, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in more detail below in conjunction with accompanying drawing example:

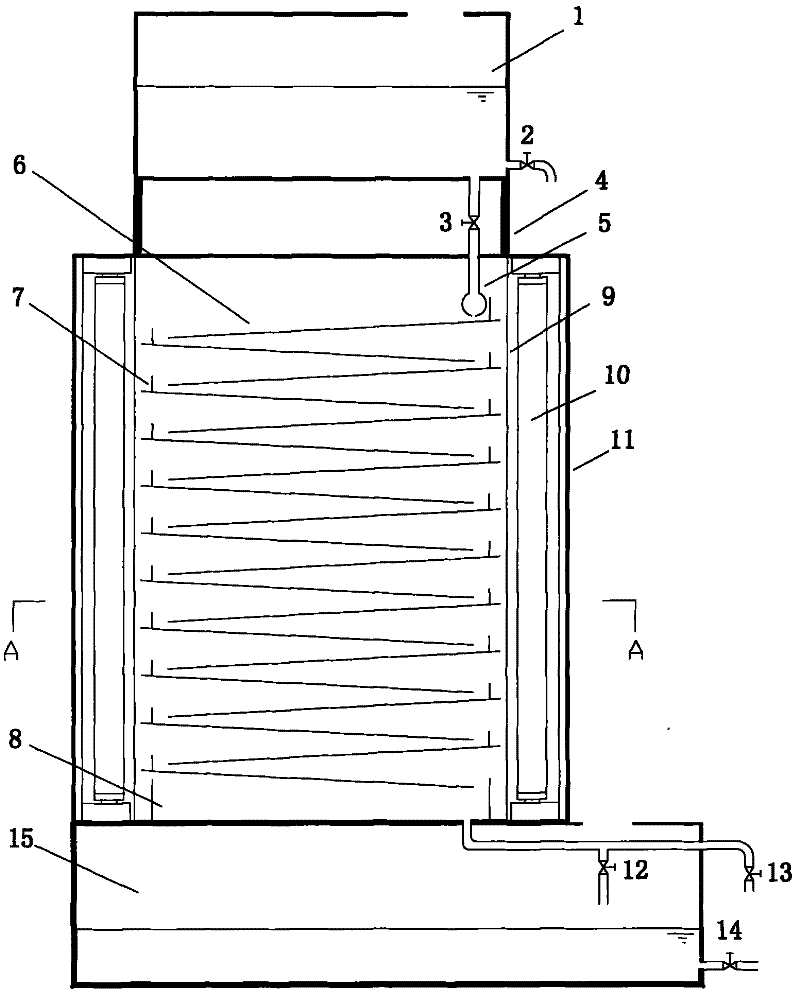

[0026] The present invention mainly consists of 20 film-carrying inclined plates, 20 baffle plates, 2 vertical plates, 4 visible light tubes, 1 water distributor, 1 water receiving tank, 1 sewage tank, 1 clean water tank, 2 Composed of partitions, 4 supporting columns, shells, valves, pipes and other components. The overall structure is attached figure 1 . exist figure 1 The meanings of the symbols in are: 1- sewage tank; 2, 12, 13, 14- valves; 3- flow control valve; 4- water tank support column; 5- water distributor; 6- inclined plate; 7- baffle; 8-receiving tank; 9-partition; 10-light source; 11-shell; 15-clean water tank;

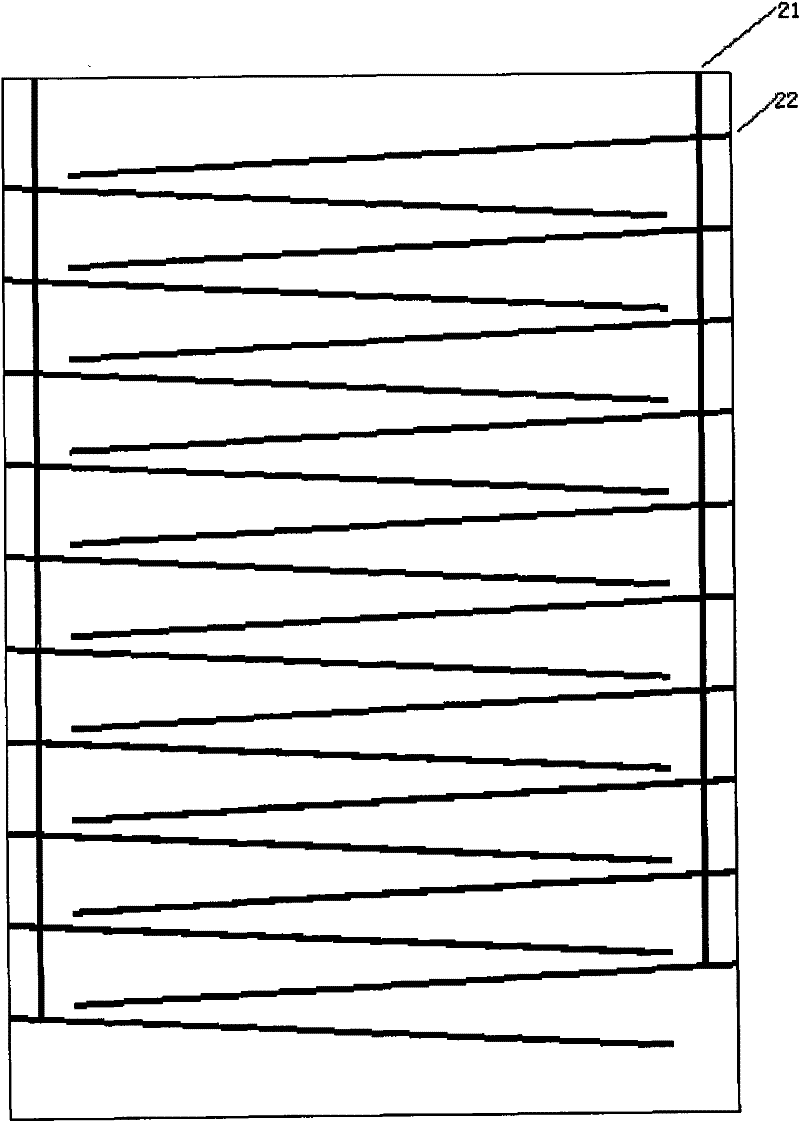

[0027] 1. There are 2 vertical panels, which are completely symmetrical organic glass panels with grooves on one side. The thickness is 6mm, the width is 310mm, and the height is 730. The grooves include two parallel longitudinal groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com