Continuous extraction method and device for sucralose esterification reaction

A technology of esterification reaction and sucralose, which is applied in the direction of liquid solution solvent extraction, etc., can solve the problems of complicated process, large pollution, high energy consumption of solvent recovery, etc., and achieve the effect of stable reaction process, improved conversion rate, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

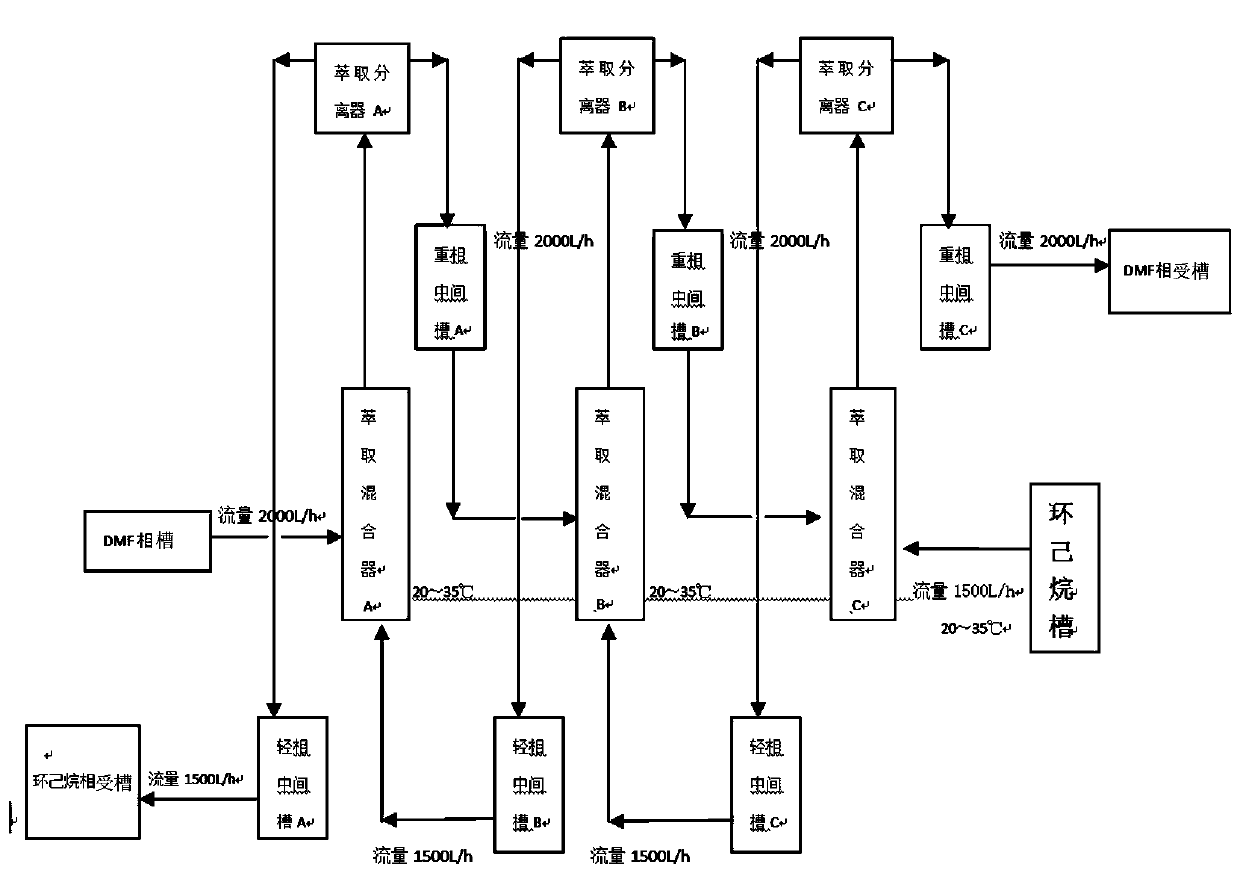

[0020] 1. A continuous extraction device for sucralose esterification reaction, comprising:

[0021] a. The cyclohexane tank is connected to the extraction mixer C through a pipeline, and the extraction mixer C is connected to the extraction separator C through a pipeline, and the extraction separator C is connected to the light phase middle tank C and the heavy phase middle tank C through a pipeline, and the heavy phase middle tank Tank C is connected to the DMF phase receiving tank through pipelines;

[0022] b. The light phase intermediate tank C is connected to the extraction mixer B through a pipeline, and the extraction mixer B is connected to the extraction separator B through a pipeline, and the extraction separator B is connected to the light phase intermediate tank B and the heavy phase intermediate tank B through a pipeline, respectively. Tank B is connected to extraction mixer C through pipelines;

[0023] c. The light phase intermediate tank B is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com