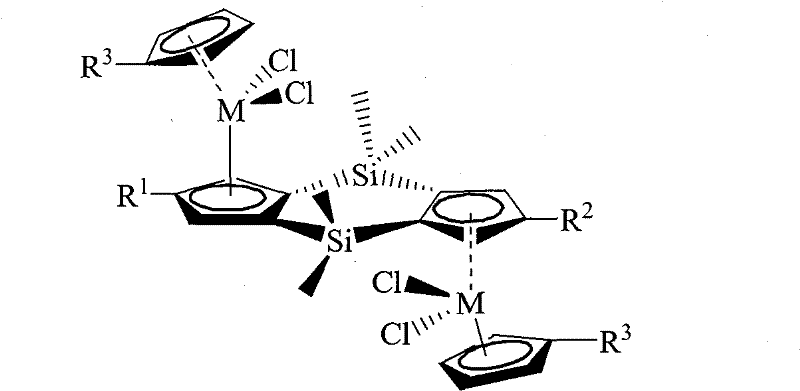

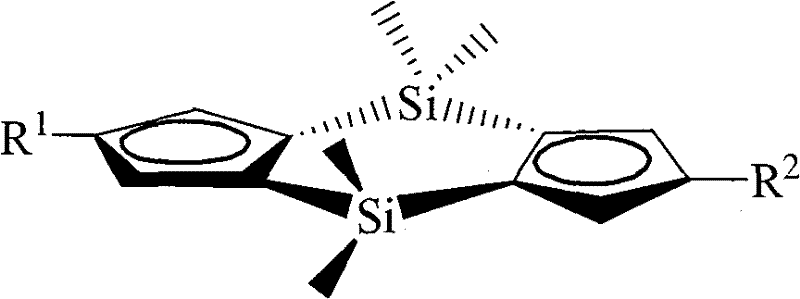

Bis-silicon-bridged dinuclear metallocene compound and preparation and application thereof

A technology of metallocene compound and silicon bridge, which is applied in the field of double-silicon bridge and dinuclear metallocene compound, can solve the problems of olefin polymerization that have not been reported, and achieve the effect of improving catalyst performance and high olefin polymerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

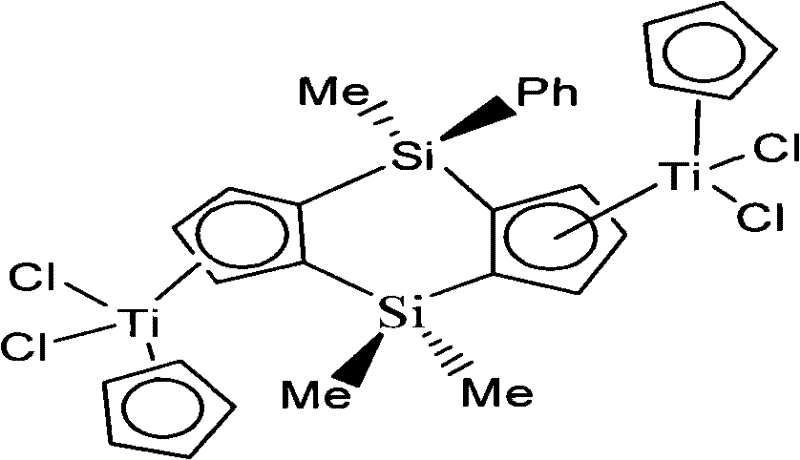

Examples

Embodiment 1

[0054] [μ,μ-(SiMe 2 ) 2 (n-BuC 5 h 2 )(CH 2 =CHCH 2 -C 5 h 2 )]Synthesis

[0055] Add 50mL (0.42mol) (CH 3 ) 2 SiCl 2 , and then add 100 mL of n-hexane, and stir evenly. Add 260mL (0.84mol) of 1.6M CpNa dropwise at 0°C, react for 6 hours, add 50mL of distilled water to wash, use a pear-shaped separatory funnel to separate liquid to remove the organic phase, wash the water phase with 3×20mL ether, and combine the organic phases , and with anhydrous MgSO 4 Dry, filter and remove solvent in vacuo. Distill under reduced pressure, collect fractions at 40-42°C / 2mmHg to obtain a light yellow liquid product. Take the above light yellow liquid product and add it to a 250mL Schlenk bottle, and dissolve it with 80mL n-hexane. Add about 53mL of 1.8M n-BuLi dropwise at 0°C, stir the reaction for 12 hours, then add 11.6mL (CH 3 ) 2 SiCl 2 and 20mLTHF, stirred for 12 hours. Precipitation occurred after the reaction, and the supernatant was filtered, concentrated until a sol...

Embodiment 2

[0059] [μ,μ-(SiMe 2 ) 2 (n-BuC 5 h 2 ) (MeC 5 h 2 )]Synthesis

[0060] Bis(dimethylsilyl) bridged dicyclopentadiene was synthesized according to the method in Example 1. Then take 4000 mL of tetrahydrofuran solution containing 1 mol of disilica-bridged dicyclopentadiene, add 1000 mL of hexane solution containing 1 mol of n-butyllithium at 0°C, react for half an hour, then naturally rise to room temperature, react for 10 hours, and drain Solvent, the solid was washed with 2000mL of n-hexane, then pumped dry, the solid was dissolved in 4000mL of THF, then cooled to -15°C with an acetone liquid nitrogen bath, 1mol of chlorobutane was added to react for 12 hours, the solvent was removed, and the solid was washed with n-hexane After extraction, add 500 mL of hexane solution containing 1 mol of n-butyllithium at 0°C for half an hour, slowly rise to about 25°C for 10 hours, then add 1.0 mol of methyl iodide at -10°C for 12 hours. In addition to solvent removal, n-hexane extrac...

Embodiment 3

[0062] [μ,μ-(SiMe 2 ) 2 ((CH 3 ) 3 Si-C5 h 2 )(CH 2 =CHCH 2 -C 5 h 2 )]Synthesis

[0063] Bis(dimethylsilyl) bridged dicyclopentadiene was synthesized according to the method in Example 1. Then take 4000 mL of tetrahydrofuran solution containing 1 mol of disilica-bridged dicyclopentadiene, add 1000 mL of hexane solution containing 1.0 mol of n-butyllithium at 0°C, react for half an hour, then naturally rise to room temperature, react for 12 hours, pump Dry the solvent, wash the solid with 1500mL of n-hexane, then drain it, dissolve the solid with 4000mL of THF, then cool it down to -15°C with an acetone liquid nitrogen bath, add 1.0mol of trimethylchlorosilane to react for 16 hours, remove the solvent, and the solid After extraction with n-hexane, add 500mL hexane solution containing 1mol n-butyllithium at 0°C for half an hour, slowly rise to about 25°C and react for 10 hours, then add 1mol allyl bromide at 0°C for reaction 14 Hours, after solvent removal, n-hexane e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com