Palladium-containing catalyst and preparation method thereof, composition prepared from palladium-containing catalyst, and application of composition

A palladium catalyst and catalyst technology, applied in the field of olefin catalysis, can solve the problems of low copolymerization activity of olefins and polar/functional monomers, low insertion rate of comonomers, etc. the effect of leaving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A preparation method containing palladium catalyst, the steps are as follows:

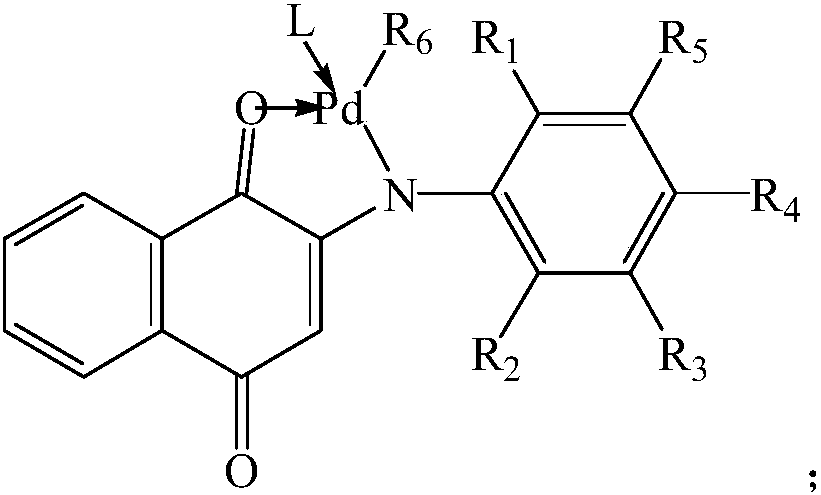

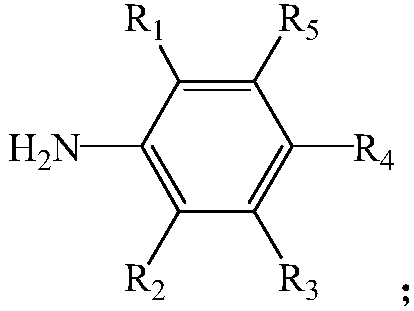

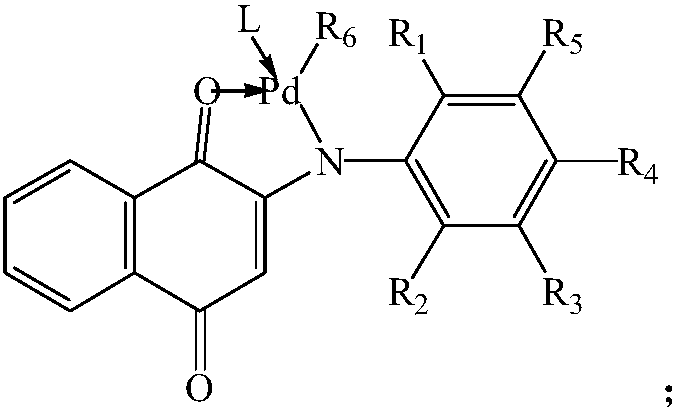

[0068] (1) Dissolve 2-hydroxy-1,4-naphthoquinone and substituted aniline in n-heptane, add trifluoroacetic acid to react to obtain anilinonaphthoquinone ligands, the reaction temperature is 100°C, the time is 15h, the reaction Initially, the molar ratio of 2-hydroxy-1,4-naphthoquinone to substituted aniline was 1:1.15, and the molar ratio of trifluoroacetic acid to 2-hydroxy-1,4-naphthoquinone was 0.33:1,2-hydroxy- The concentration of 1,4-naphthoquinone in n-heptane is 0.125mol / L, and the structural formula of substituted aniline is as follows:

[0069]

[0070] In the formula, R 1 is ethyl, R 2 is ethyl, R 3 is methyl, R 4 is methyl, R 5 It is a methyl group, and after the reaction, the anilinaquinone ligands are purified by toluene recrystallization;

[0071] (2) Dissolving the anilino-naphthoquinone ligands in toluene, adding sodium hydride to react to obtain a ligand salt compo...

Embodiment 2

[0078] A preparation method containing palladium catalyst, the steps are as follows:

[0079] (1) Dissolve 2-hydroxy-1,4-naphthoquinone and substituted aniline in toluene, add trifluoroacetic acid to react to obtain aniline naphthoquinone ligands, the reaction temperature is 110°C, the time is 6h, when the reaction starts , the molar ratio of 2-hydroxyl-1,4-naphthoquinone to substituted aniline is 1:1, the molar ratio of trifluoroacetic acid to 2-hydroxyl-1,4-naphthoquinone is 0.32:1, 2-hydroxyl-1, The concentration of 4-naphthoquinone in toluene is 0.1mol / L, and the structural formula of substituted aniline is as shown in embodiment 1, and in the formula, R 1 is methyl, R 2 is methyl, R 3 is ethyl, R 4 is ethyl, R 5 After the reaction, the anilinaquinone ligands are purified by n-hexane extraction;

[0080] (2) Dissolving the anilinaquinone ligands in tetrahydrofuran, adding sodium hydride to react to obtain a ligand salt compound, the temperature of the reaction is 40°C...

Embodiment 3

[0085] A preparation method containing palladium catalyst, the steps are as follows:

[0086](1) Dissolve 2-hydroxy-1,4-naphthoquinone and substituted aniline in chlorobenzene, add trifluoroacetic acid to react to obtain anilino-naphthoquinone ligands, the reaction temperature is 130°C, the time is 6h, and the reaction starts , the molar ratio of 2-hydroxy-1,4-naphthoquinone to substituted aniline is 1:1.02, and the molar ratio of trifluoroacetic acid to 2-hydroxy-1,4-naphthoquinone is 0.32:1,2-hydroxy-1 , the concentration of 4-naphthoquinone in chlorobenzene is 0.11mol / L, and the structural formula of substituted aniline is as shown in embodiment 1, and in the formula, R 1 is isopropyl, R 2 is isopropyl, R 3 is methyl, R 4 is methyl, R 5 It is a methyl group, and after the reaction, the anilinaquinone ligands are purified by tetrahydrofuran recrystallization;

[0087] (2) Anilinaquinone ligands are dissolved in dichloromethane, and potassium hydride is added to react to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com