Argon blowing method at bottom of steel ladle for continuously casting steel

A technology for bottom blowing argon and ladle, which is applied to the field of bottom blowing argon for continuous casting ladle, can solve the problems of long processing cycle, speeding up production rhythm, insufficient soft blowing time and insufficient standing time to limit the removal effect of inclusions, etc., to improve the cleanliness. , Alleviate the impact and avoid the effect of excessive molten steel temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

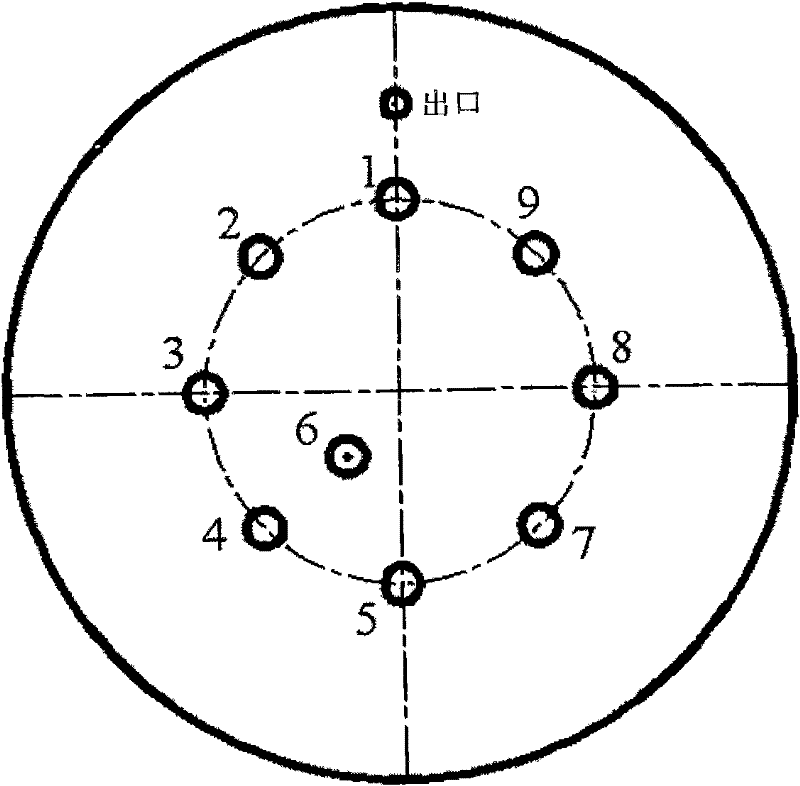

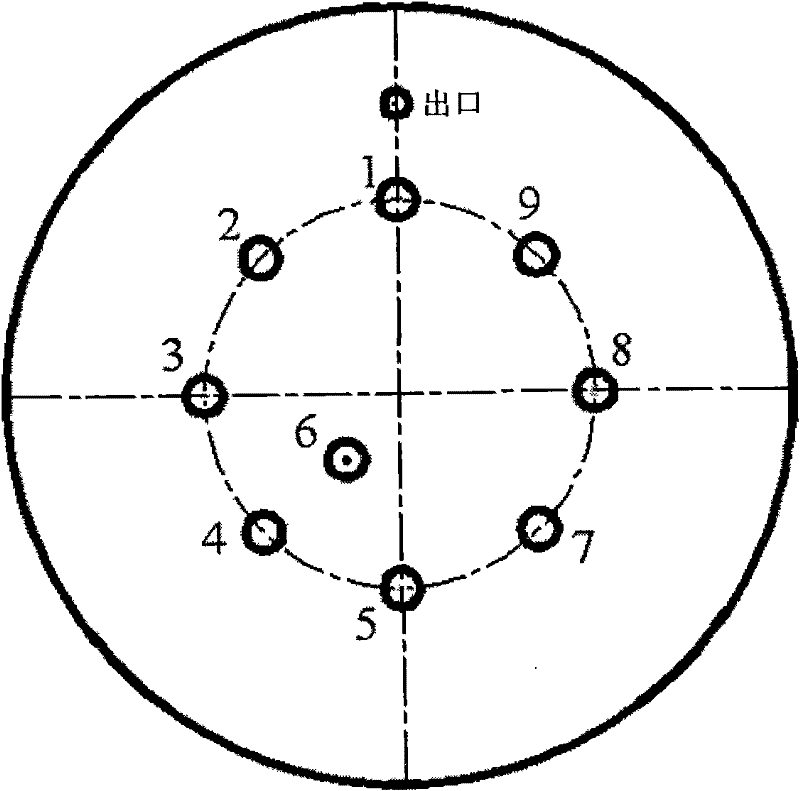

[0014] In the steelmaking equipment, the bottom of the 150t ladle is equipped with diffused air-permeable bricks. After the ladle is refined, it enters the continuous casting station directly to start pouring. When the ladle is poured, the gas supply switch at the bottom of the ladle is turned on to blow argon at the bottom of the ladle to supply gas. located at figure 1 In 6, this position is the bottom blowing position used in refining outside the furnace, the gas supply flow rate is 200NL / min, the gas supply pressure is 0.5MPa, when the casting volume reaches 50%, the bottom blowing gas is stopped, and the sampling analysis in the early stage after casting is completed, Compared with the casting process without argon blowing, the inclusion number density of the sample is reduced by 52%, and when the whole bottom blowing of argon is carried out, the inclusion number density is reduced by 66%.

Embodiment 2

[0016] The implementation ladle is still 150t. After the ladle is refined and enters the casting station to start pouring, the air supply device is turned on at the same time. The air supply method is double spraying. figure 1 3 and 8 positions in. The gas supply flow rate is 305NL / min, the gas supply pressure is 0.4MPa, and when the gas supply is stopped by double-hole injection to 20% of the casting volume, the number density of inclusions is reduced by 29% compared with the casting process without argon blowing; the casting volume reaches 40% %When the gas supply is stopped, the number density of inclusions decreases by 41%; when the gas is supplied all the way, the number density of inclusions decreases to 63%.

Embodiment 3

[0018] The implementation ladle is 150t. After the ladle is refined, it enters the casting station and starts the air supply device at the same time as the pouring. The air supply method is three-hole injection. figure 1 In the 3, 5 and 8 positions, the gas supply flow rate is 700NL / min, the gas supply pressure is 0.2MPa, and the gas supply is stopped when the double hole is blown to 30% of the casting volume. Compared with the casting process without argon blowing, the number density of inclusions It is reduced by 27%; when the casting volume reaches 50%, the gas supply is stopped, and the number density of inclusions is reduced by 33%; when the gas is supplied throughout, the number density of inclusions is reduced to 59%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com