Viscose filament yarn semi-continuous spinning machine and spinning process thereof

A viscose filament and spinning process technology, applied in the field of spinning, can solve the problems of large retraction rate, limited application, easy wrinkling, etc., and achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

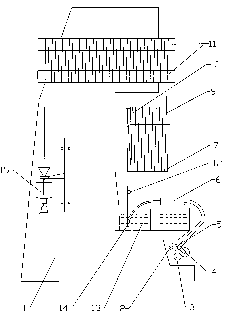

[0029] Embodiment 1, the present invention is illustrated by transforming the semi-continuous spinning machine that model is R535A. Such as figure 2 Shown, a kind of viscose filament semi-continuous spinning machine comprises frame 1, and frame 1 is provided with glue spraying device, lower coagulation roller 7 and upper coagulation roller 9, acid removal roller 11, scraping acid bar 12, Bath 13, spinneret 14 and centrifuge tank 15, glue spraying device includes viscose pipe 2, pump shaft 3, metering pump 4, bridge frame 5 and filter 6, and one end of upper coagulation roller 9 near frame 1 is provided with upper pulling Stretch dish 10, lower coagulation roller 7 is coaxially provided with lower drafting dish 8, and the outer diameter of lower drafting dish 8 is greater than the outer diameter of upper drafting dish 10, and the outer diameter of lower drafting dish 8 is less than that of upper coagulation roller 9. outside diameter.

[0030] The spinning process of the vis...

Embodiment 2

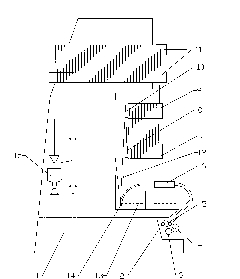

[0037] Embodiment 2, the present invention is explained by transforming the semi-continuous spinning machine that model is R535A. Such as image 3 Shown, a kind of viscose filament semi-continuous spinning machine comprises frame 1, and frame 1 is provided with glue spraying device, lower coagulation roller 7 and upper coagulation roller 9, acid removal roller 11, scraping acid bar 12, Bath 13, spinneret 14 and centrifuge tank 15, glue spraying device comprises viscose pipe 2, pump shaft 3, metering pump 4, bridge frame 5 and filter 6, and one end of upper coagulation roller 9 near frame 1 is provided with two The upper drafting disc is the upper drafting disc 10 and the upper drafting disc 16, the upper drafting disc 16 is arranged between the upper drafting disc 10 and the upper coagulation roller 9, and the lower coagulation roller 7 is coaxially provided with the lower drafting disc 8. The outer diameter of the lower drafting disc 8 is larger than that of the upper drafti...

Embodiment 3

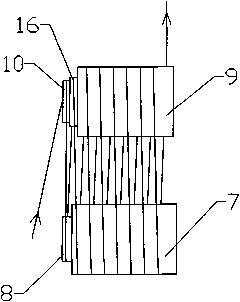

[0045] Embodiment 3, the present invention is explained by transforming the semi-continuous spinning machine that model is R535A. Such as Figure 4 Shown, a kind of viscose filament semi-continuous spinning machine comprises frame 1, and frame 1 is provided with glue spraying device, lower coagulation roller 7 and upper coagulation roller 9, acid removal roller 11, scraping acid bar 12, Bath 13, spinneret 14 and centrifuge tank 15, glue spraying device comprises viscose pipe 2, pump shaft 3, metering pump 4, bridge frame 5 and filter 6, and one end of upper coagulation roller 9 near frame 1 is provided with two The upper drafting disc is the upper drafting disc 10 and the upper drafting disc 16, the upper drafting disc 16 is arranged between the upper drafting disc 10 and the upper coagulation roller 9, and the lower coagulation roller 7 is coaxially provided with two lower drafting discs. The stretching discs are the lower drafting discs 8 and the lower drafting discs 17, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com