Variable-volume type multi-chamber hydraulic water pump

A hydraulic water pump, variable capacity technology, applied in the direction of rotary piston pump, pump, rotary piston machine, etc., can solve the problems of wear, can not work normally, can not transport water, etc., achieve high output efficiency, obvious energy saving effect, The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

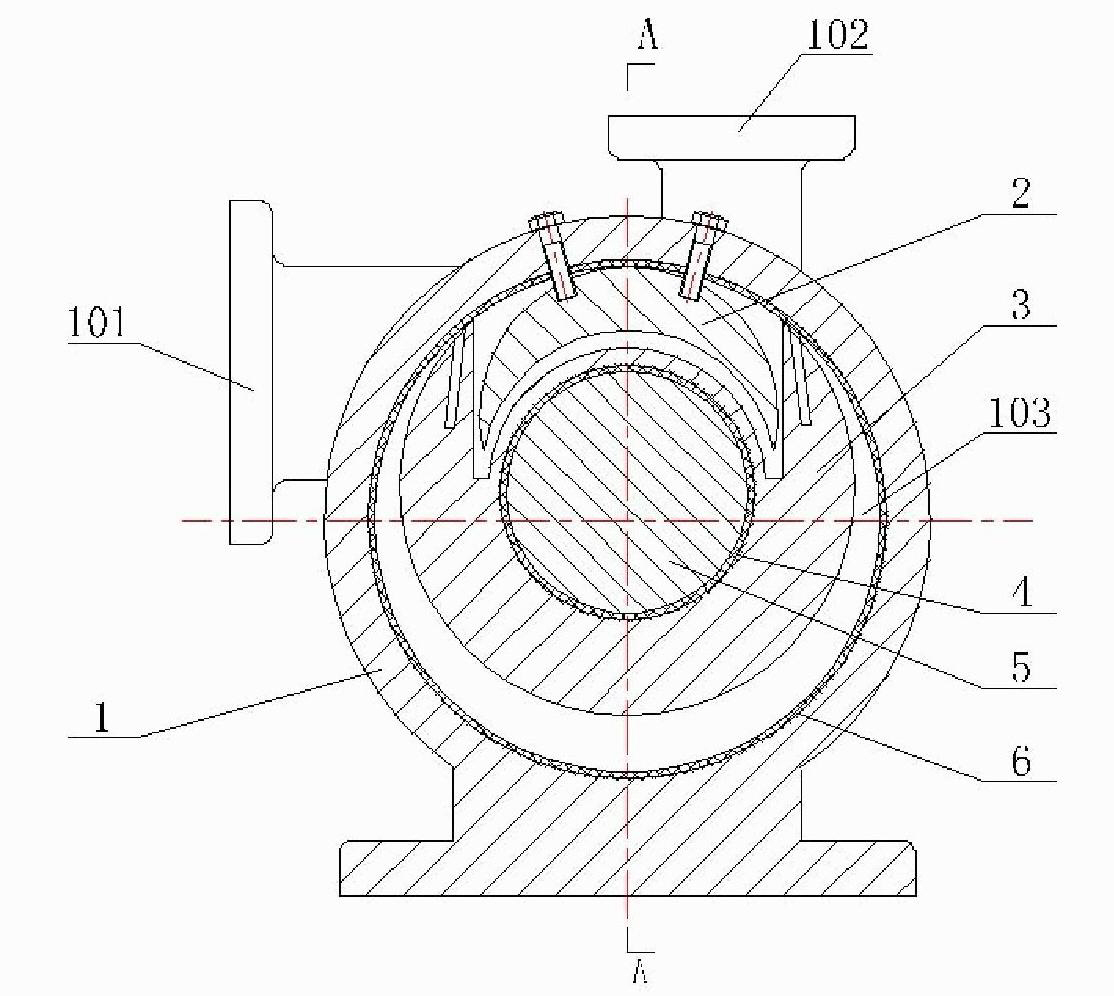

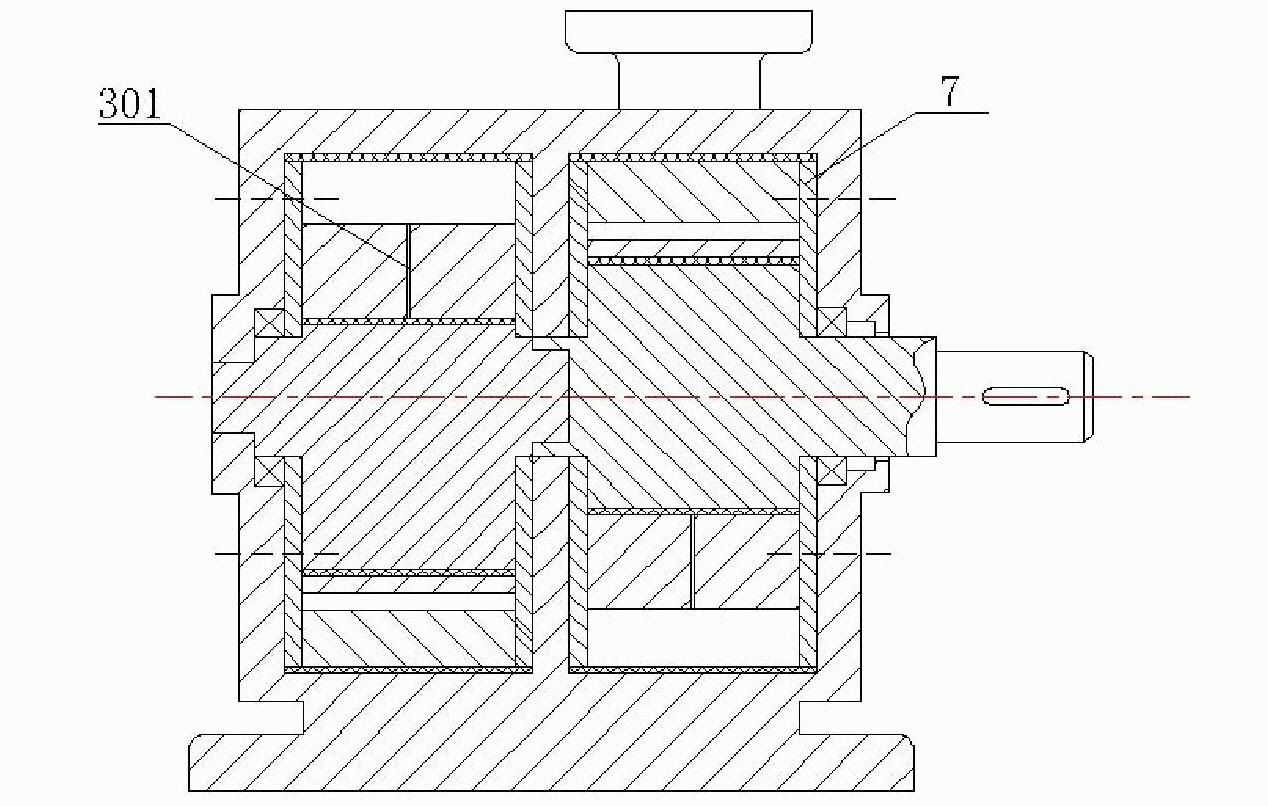

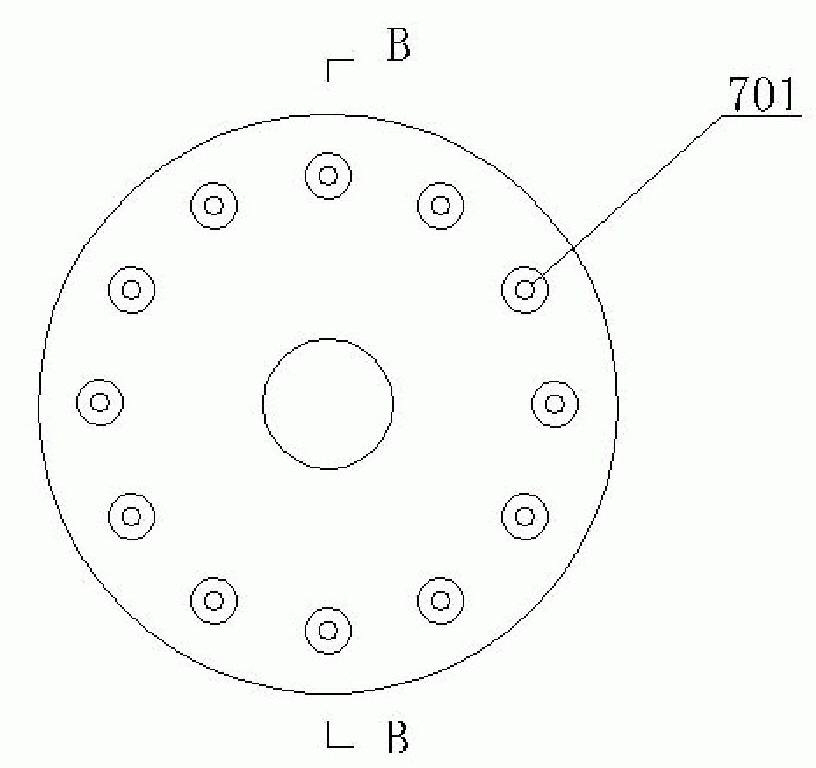

[0034] Such as Figure 1 ~ Figure 4 As shown, the variable capacity multi-chamber hydraulic water pump includes a pump body 1, and a plurality of working chambers 103 are arranged in the pump body 1. In this embodiment, two working chambers are taken as an example, and each working chamber is corresponding to the pump body 1. The position 103 is respectively provided with an inlet 101 and an outlet, and the two outlets are combined into a total outlet 102 on the pump body 1 . The two adjacent working chambers 103 are spaced apart from each other. On the pump body 1, an eccentric shaft 5 is installed through a bearing along the centerline of the working chamber 103. The eccentric shaft 5 can be integrated or divided into multiple sections and connected by splines. , this embodiment takes the latter as an example. On the eccentric shaft 5, a pendulum rotor 3 is set inside the pump body 1. The number of the pendulum rotors 3 is the same as that of the working chamber 103, and th...

Embodiment 2

[0036] Such as Figure 5 As shown, the variable capacity multi-chamber hydraulic water pump includes a pump body 1, and a plurality of working chambers 103 are arranged in the pump body 1. In this embodiment, three working chambers are taken as an example, and there are three corresponding suspension rotors 3, eccentric The shaft 5 is divided into three sections and connected by splines. Others are with embodiment 1.

Embodiment 3

[0038] Such as Figure 6 As shown, there are two working chambers 103 in the pump body 1, the two working chambers 103 are separated by a partition, the eccentric shaft 5 is integrated, and the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com