Four-pole electric machine rotor sheet for injection molding machine

A technology for motor rotor and rotor punching, which is applied to the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve problems such as discomfort, and achieve the effect of eliminating electromagnetic noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

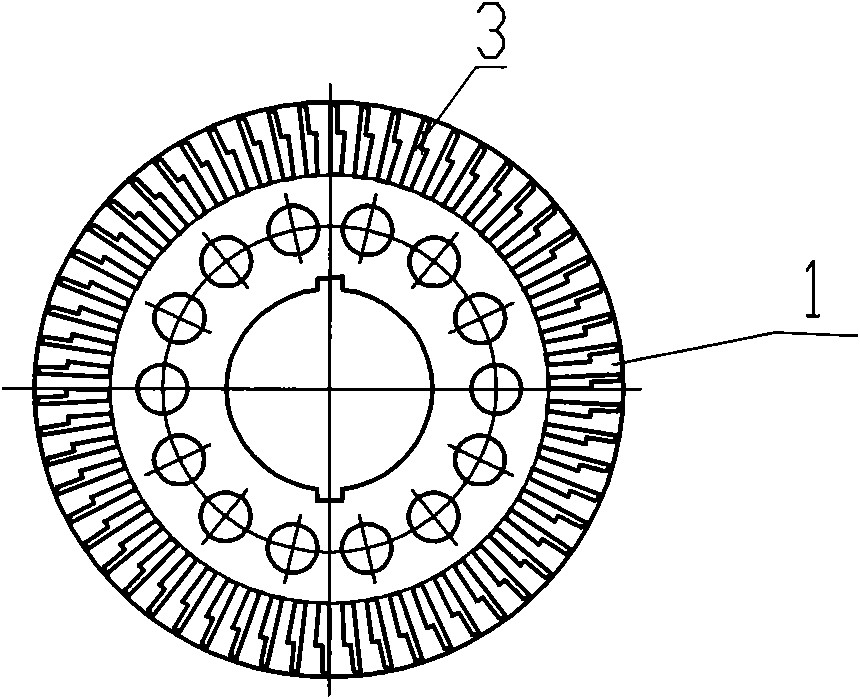

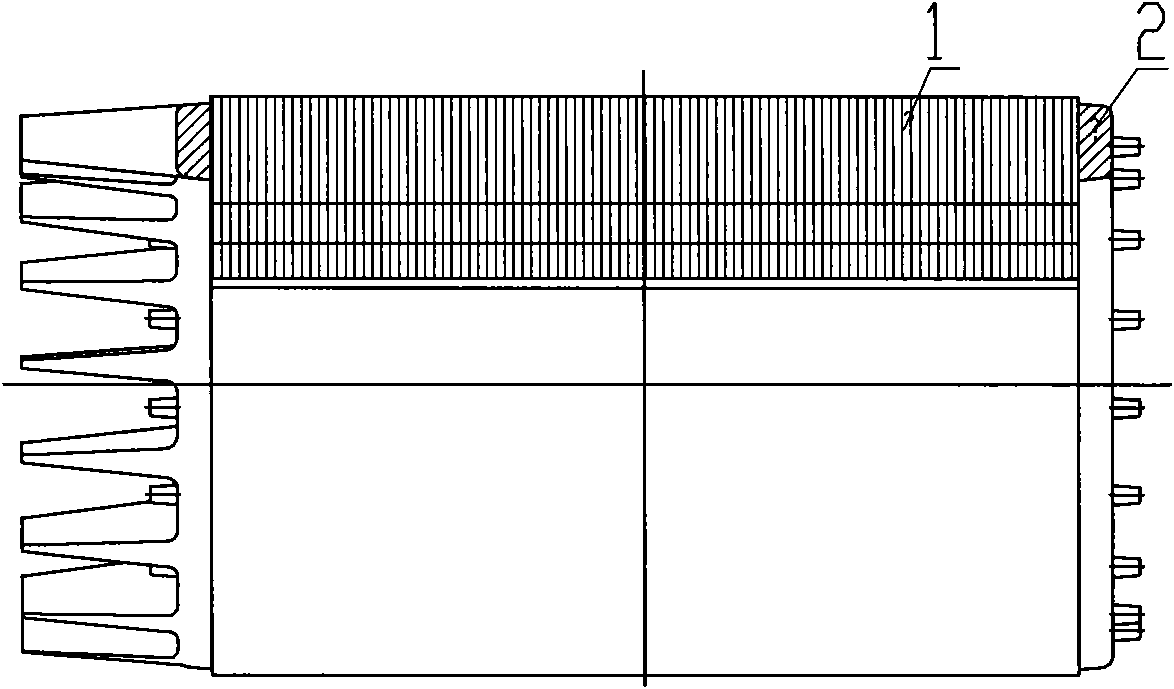

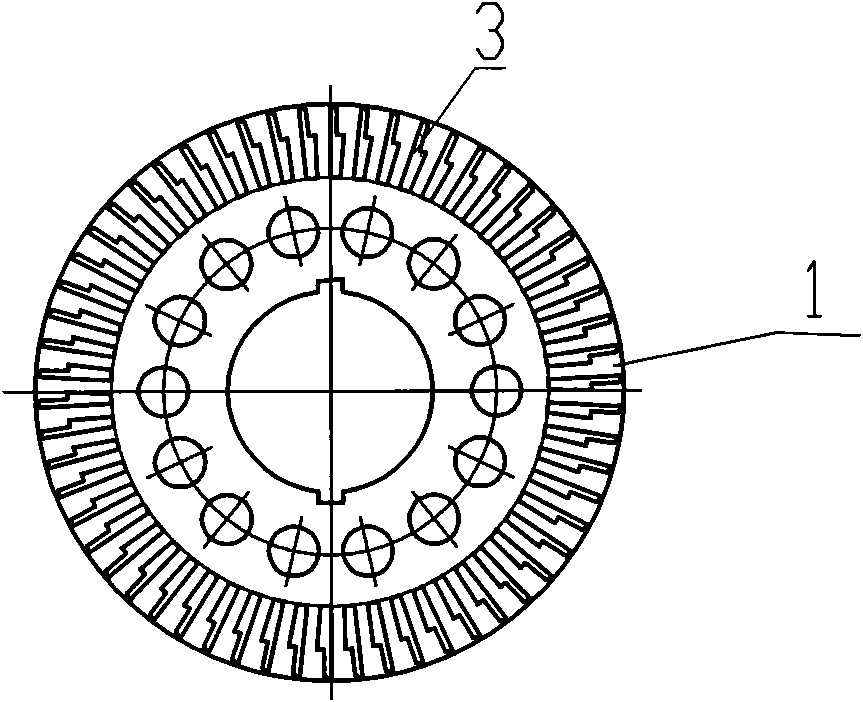

[0011] The present invention only needs to change the stamping die of the rotor punching sheet, and punch out the silicon steel sheet on the punching machine ( figure 1 ) The rotor punching sheet is provided with 52 slots 3 on the rotor punching body 1 . Average groove width: 3.9mm, groove depth: 57.3mm. Then die-cast a certain number of rotor punch bodies 1 and aluminum 2 on a dedicated rotor die-casting machine to form a motor rotor. The proposal of the present invention does not change the original assembly mode of the motor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com