Combine

A combine harvester and engine technology, applied to harvesters, steering mechanisms, guiding agricultural machinery, etc., can solve the problems of high cost of parts, inability to simply form a gearbox, troublesome operation, etc., achieve small size and light weight, and realize light Quantitative, easy-to-maintain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] Hereinafter, embodiments embodying the invention of the present application will be described with reference to the drawings.

[0091] (1), the general structure of the combine harvester

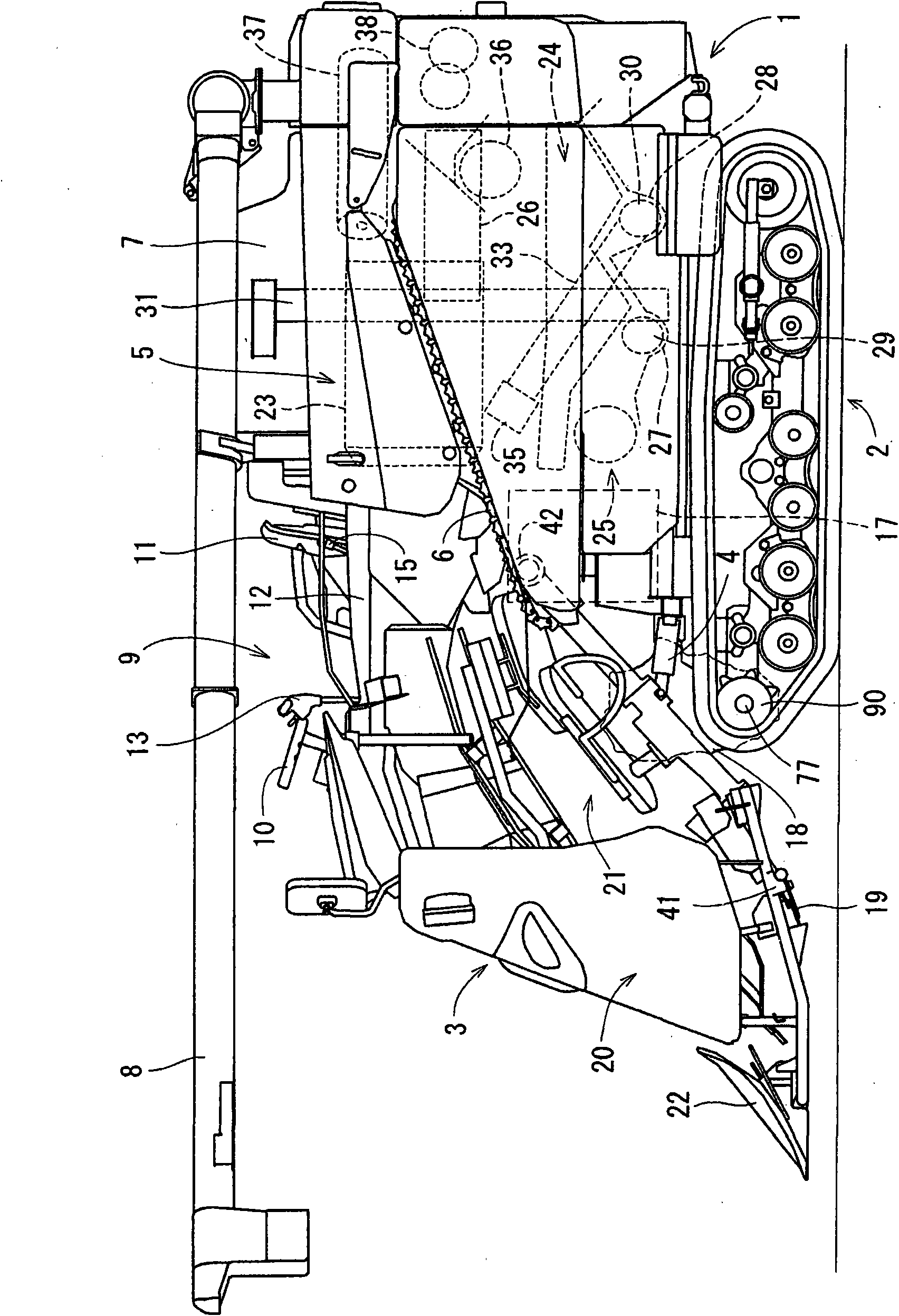

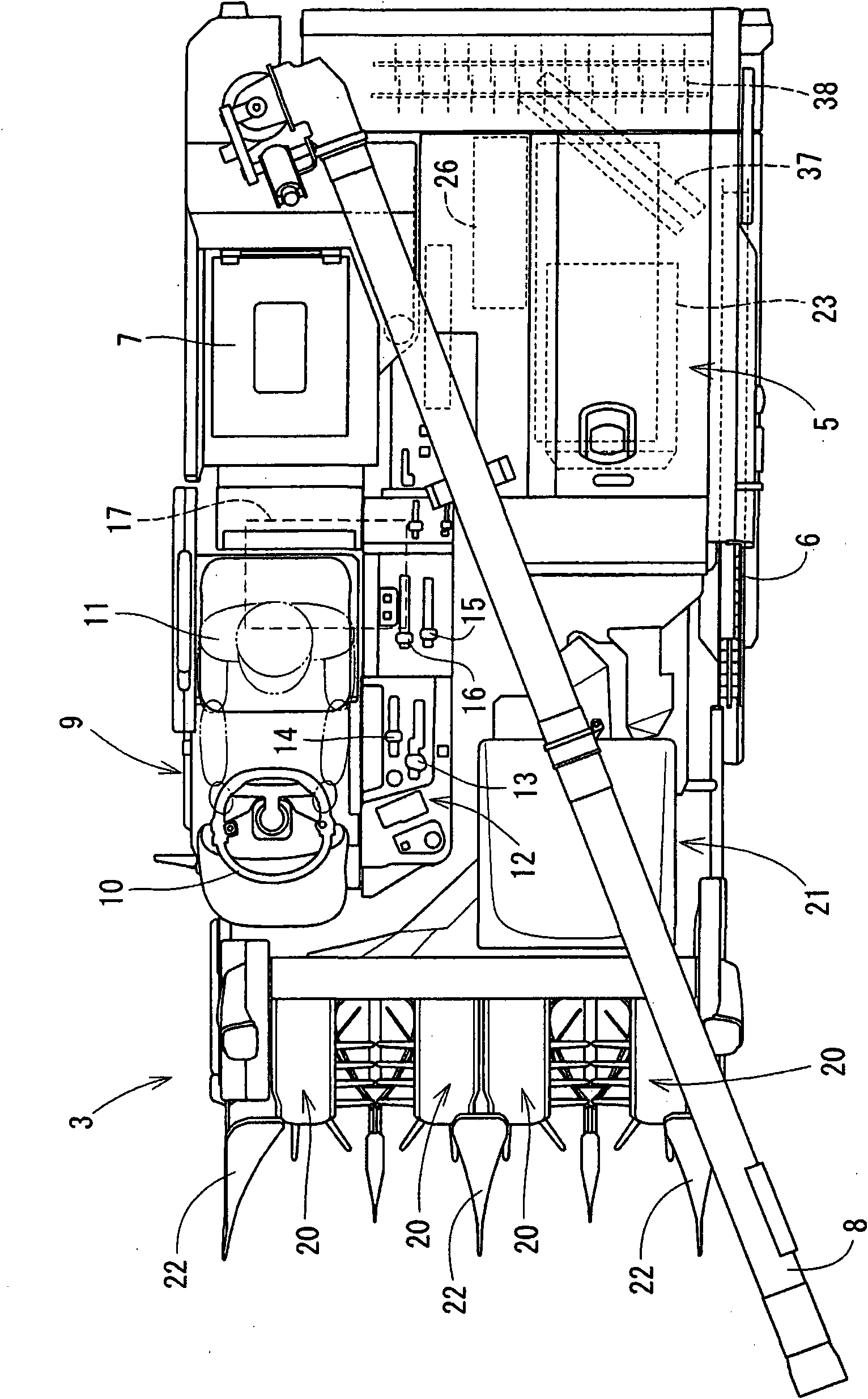

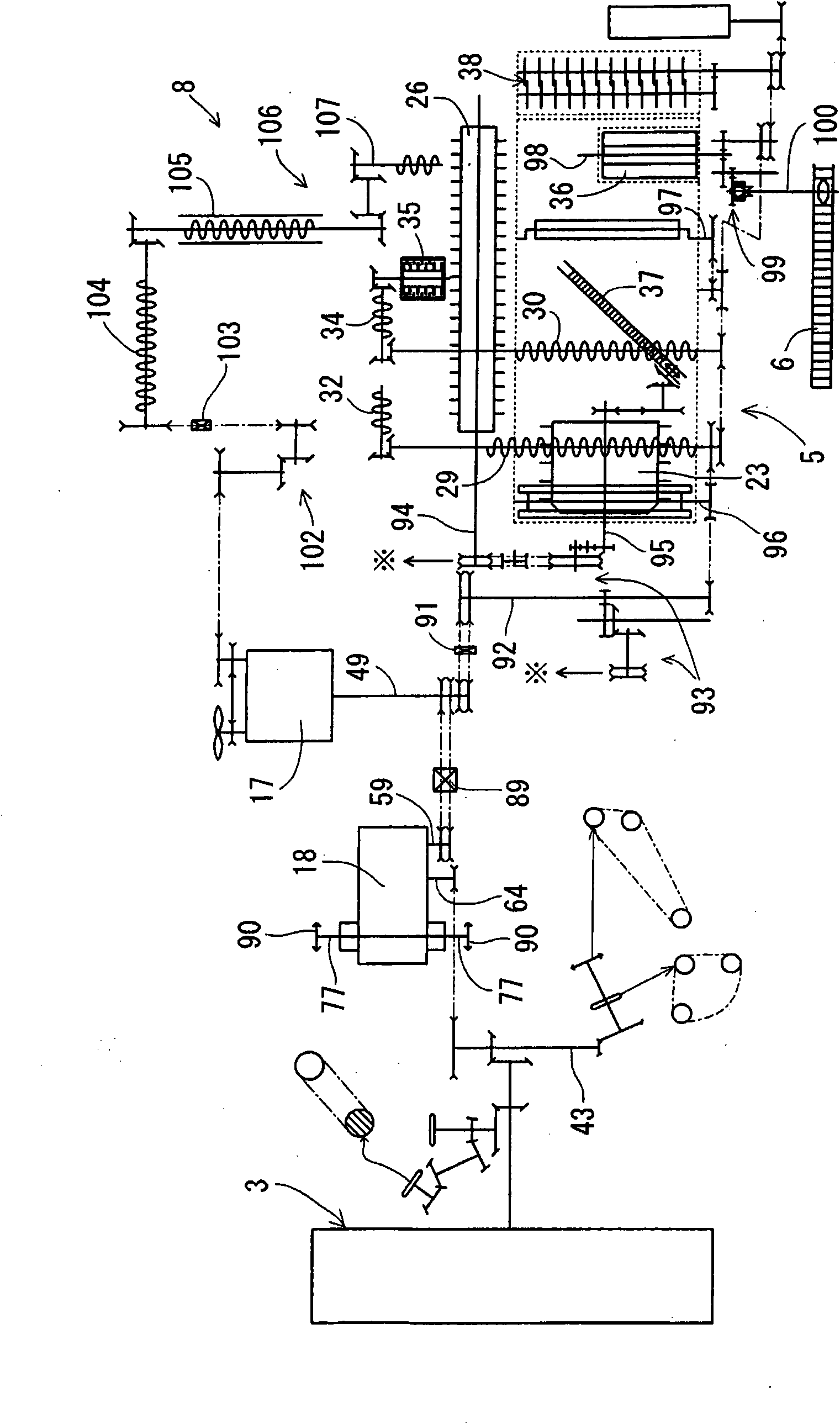

[0092] First, refer to figure 1 and figure 2 The schematic structure of a combine harvester is demonstrated.

[0093] A combine harvester which is an example of a traveling vehicle is equipped with the traveling body 1 supported by the left-right pair of traveling crawler belt 2 which is a traveling part. The front portion of the traveling body 1 is equipped with a harvesting device 3 that can be adjusted up and down by a single-acting hydraulic cylinder 4 to harvest the grain stalks (uncut grain stalks) of the farm while harvesting.

[0094] The threshing apparatus 5 with the feed chain 6, and the grain box 7 which store|stores the grain after threshing are mounted side by side on the traveling body 1. As shown in FIG. In this case, the threshing apparatus 5 is arrange|positione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com