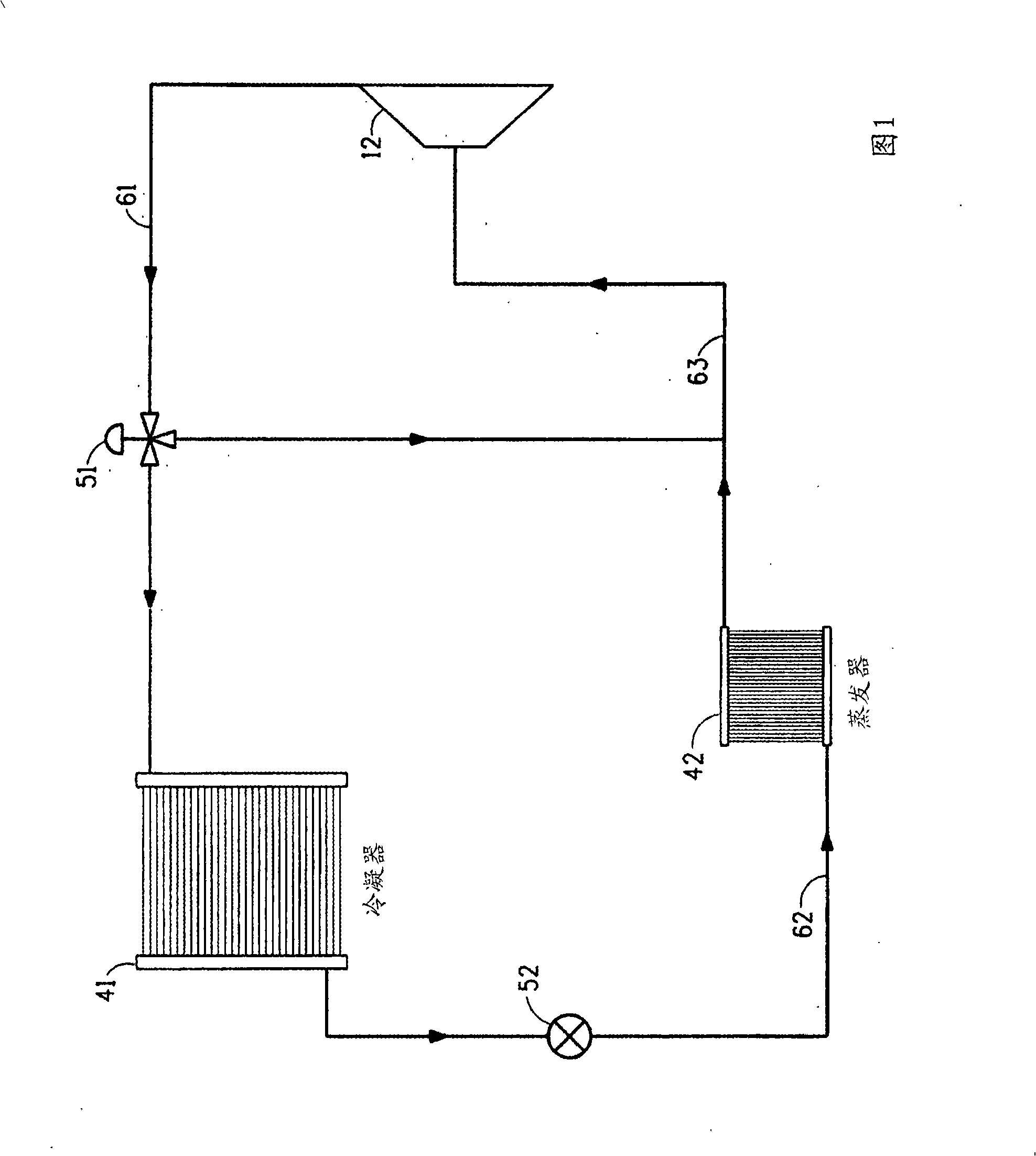

Method for circulating selected heat transfer fluids through a closed loop cycle

A heat transfer fluid, selected technology, applied in the direction of fluid flow, chemical instruments and methods, materials for heat exchange, etc., can solve problems such as barrier properties to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

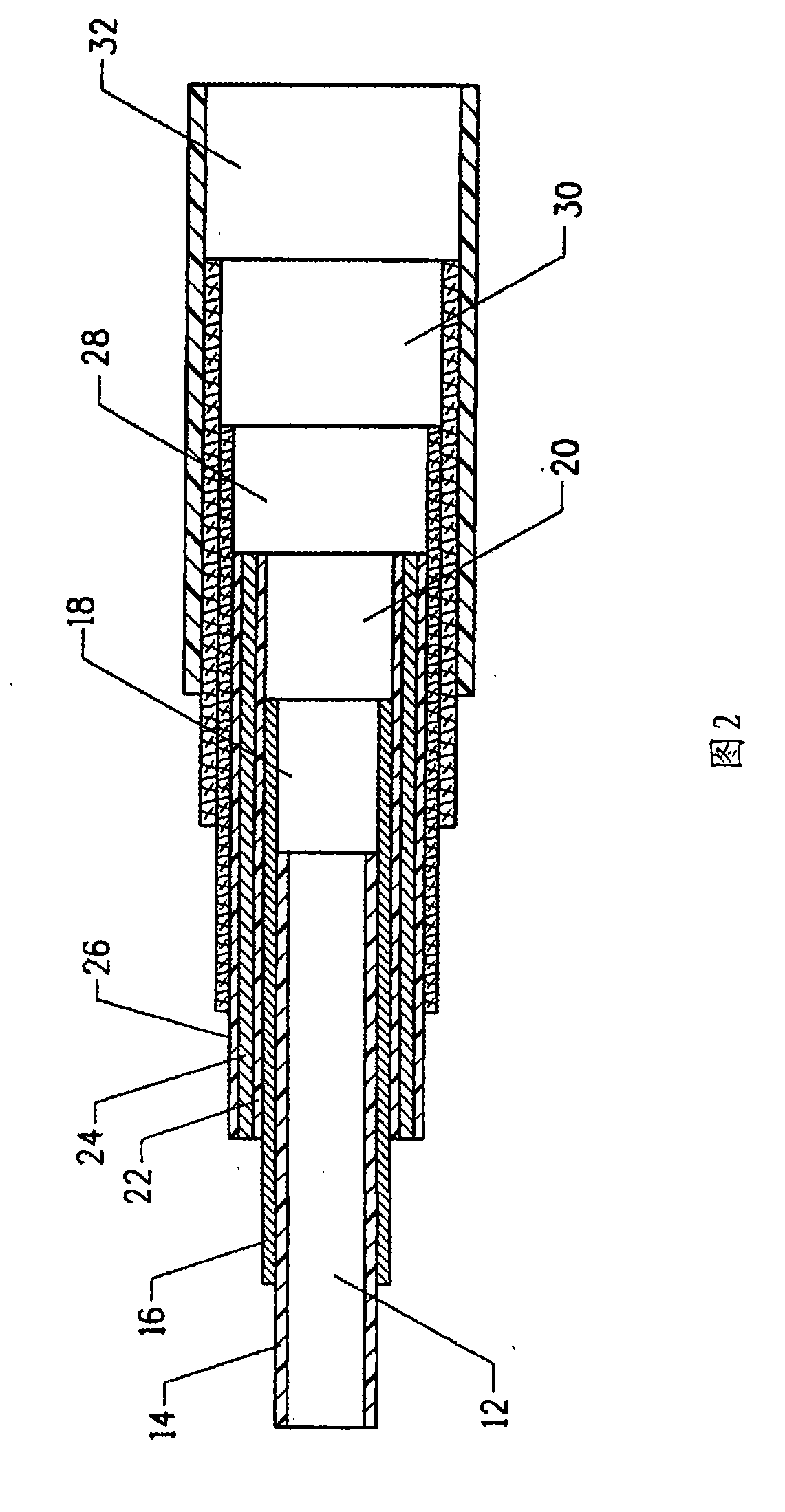

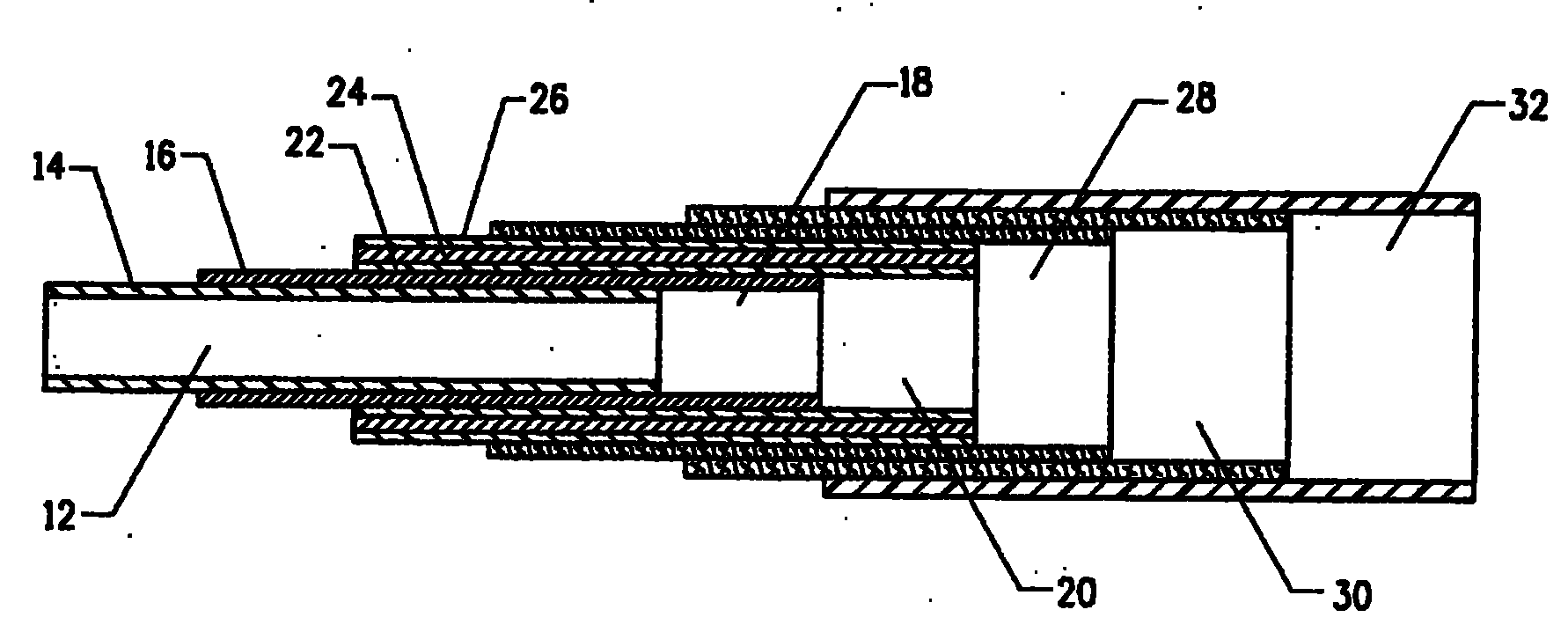

[0190] According to one embodiment of the present invention, the hose is constructed in the following manner. A solid rod-shaped mandrel with a diameter of 6.4 mm was first produced. Extruded on the mandrel by 0.65mm thick 42 (high MWA 66 commercially available from E.I. du Pont de Nemours and Company) inner layer and 0.1 mm thick 4206 (maleic anhydride grafted polyethylene commercially available from E.I. du Pont de Nemours and Company) outer tie layer. The assembly was then laminated with a metal-polymer laminate available from James Dawson Enterprises Ltd., Lachine (Quebec, Canada) under the trade designation BFW46. The laminate consisted of an inner layer of low density polyethylene, a tie layer of EEA, an aluminum foil (10 microns thick) and an outer layer of polyethylene terephthalate (PET) with a total thickness of 0.1 mm. Lamination is performed using a heated die with appropriately sized channels to pass the assembly through. The assembly from the previous step ...

Embodiment 2

[0192] Hose permeability was determined on hose samples as described in Example 1 according to the method described in standard SAE J2064. Cut lengths of hose and connect end to end to contain the refrigerant. Add 70 volume percent refrigerant to the hose. The hose was then placed in an oven and kept at 80°C for 28 days. Periodically remove the hose and weigh it to determine refrigerant loss. The total loss or penetration rate is then determined in kg / m2 / yr. The results are shown in Table 9.

[0193] Table 9

[0194] Refrigerant composition

[0195] The results show that the hose permeability of the fluoroolefin composition is at least equivalent to that of R134a. Since R32 is a small molecule, it contributes the most to hose penetration. Compositions containing mainly fluoroolefins with a small amount of R134a have significantly lower permeabilities than shown for R134a alone, indicating that fluoroolefins have an overall lower permeation rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com