Polishing head for inner surface of elongated bend pipe

A technology of inner surface polishing and polishing head, applied in surface polishing machine tools, grinding/polishing equipment, abrasives, etc., can solve the problems of difficult uniform polishing, existence of processing blind spots, etc., and achieve the effect of uniform polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

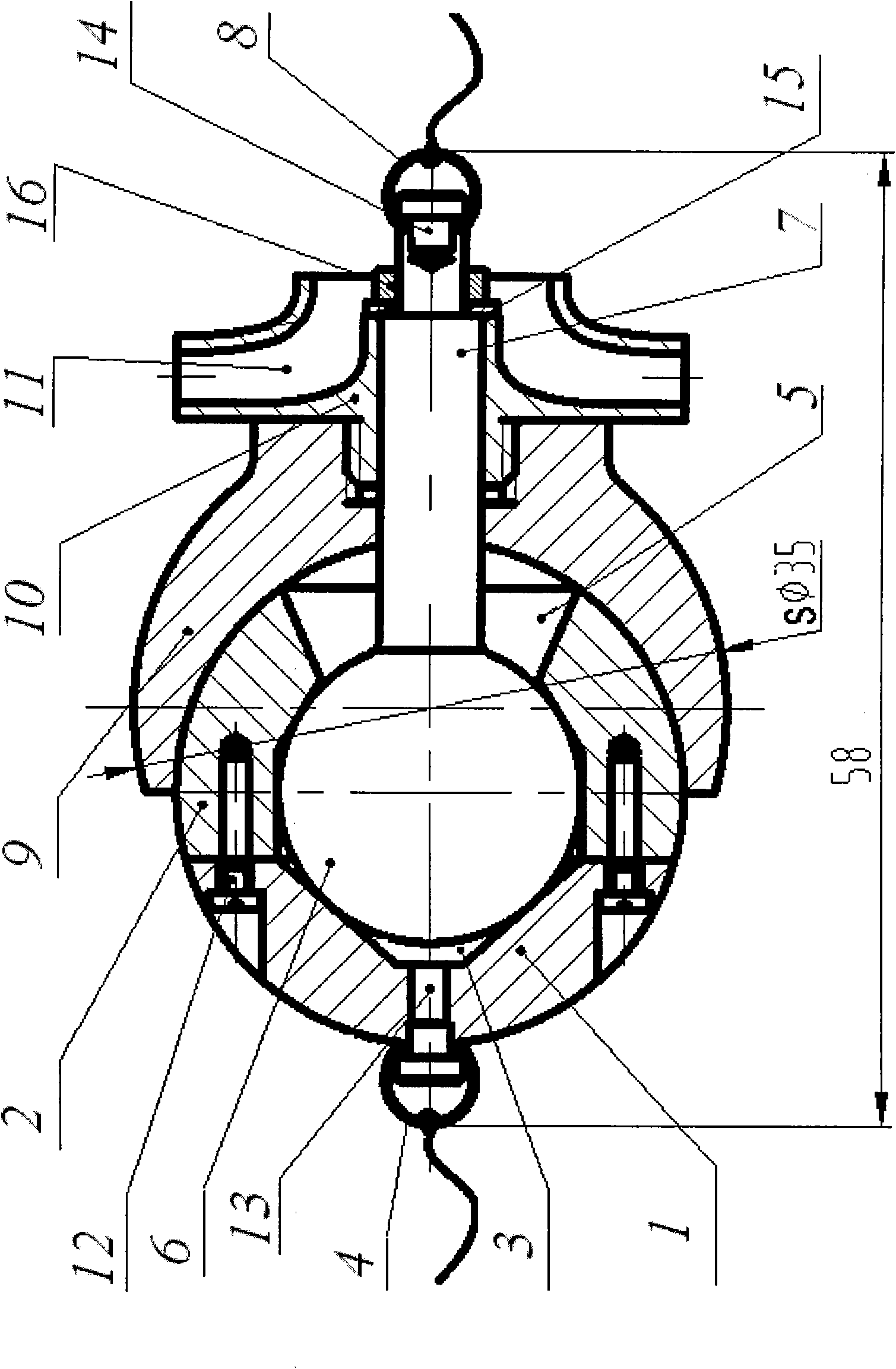

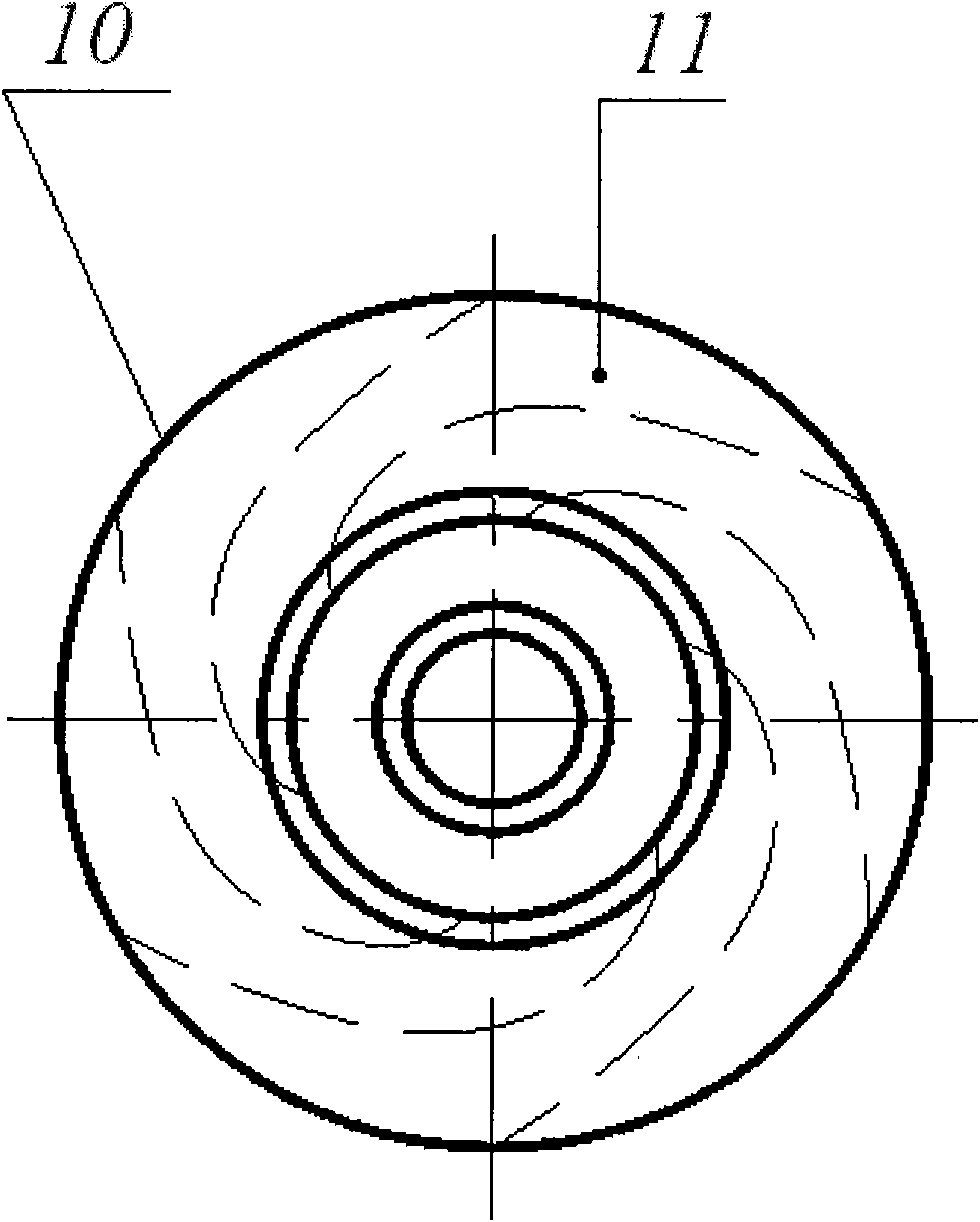

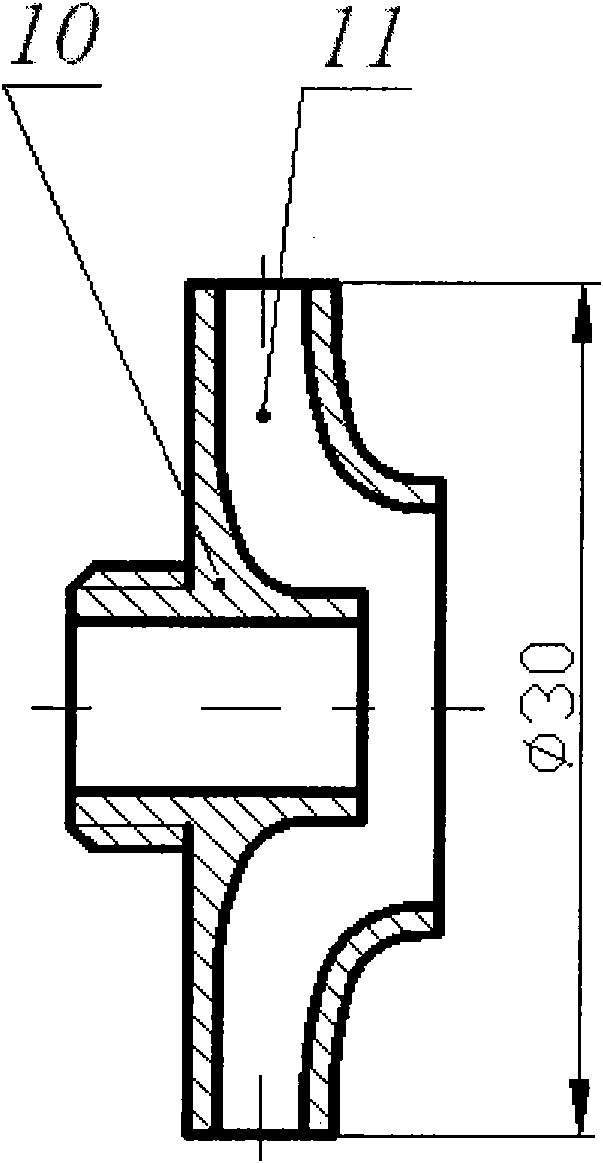

[0008] The structural features of the inner surface polishing head of the slender curved pipe of the present invention are specifically described below, see figure 1 As shown, the traction part 1 is a spherical cap less than 1 / 2, and the steering part 2 is a spherical cap larger than 1 / 2. join together. The inside of the ball cage is a ball cavity 3, and the shape of the ball cavity 3 is a sphere or a polyhedron, and the latter is easy to process. The front rotating pull ring 4 is installed on the top of the spherical crown of the traction part 1, and this installation is realized by the front screw cover 13. There is a bending hole 5 at the top of the spherical crown of the steering part 2 . The ball head 6 is a sphere, located in the ball head cavity 3, connected to one end of the rotating shaft 7; the other end of the rotating shaft 7 protrudes from the bending hole 5, and the rear rotating pull ring 8 is connected to this end, and the installation is realized through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com