Universal tensile covering film packaging machine

A packaging machine, a general-purpose technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of complex system structure, low reliability, and the inability of stretch wrap packaging machines to automatically adapt to changes in film width and size, etc. To achieve the effect of simple system structure, high reliability and improved system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

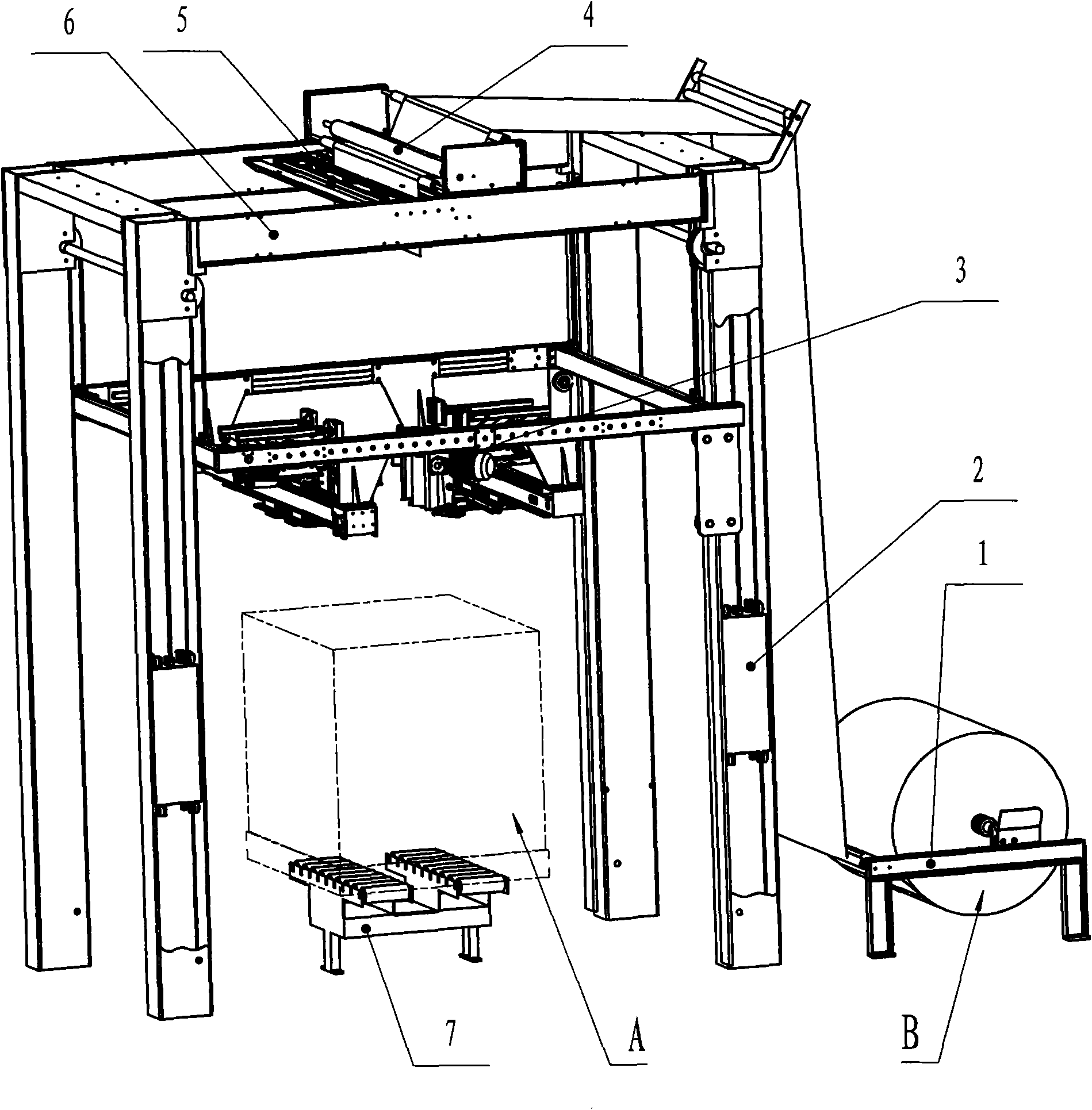

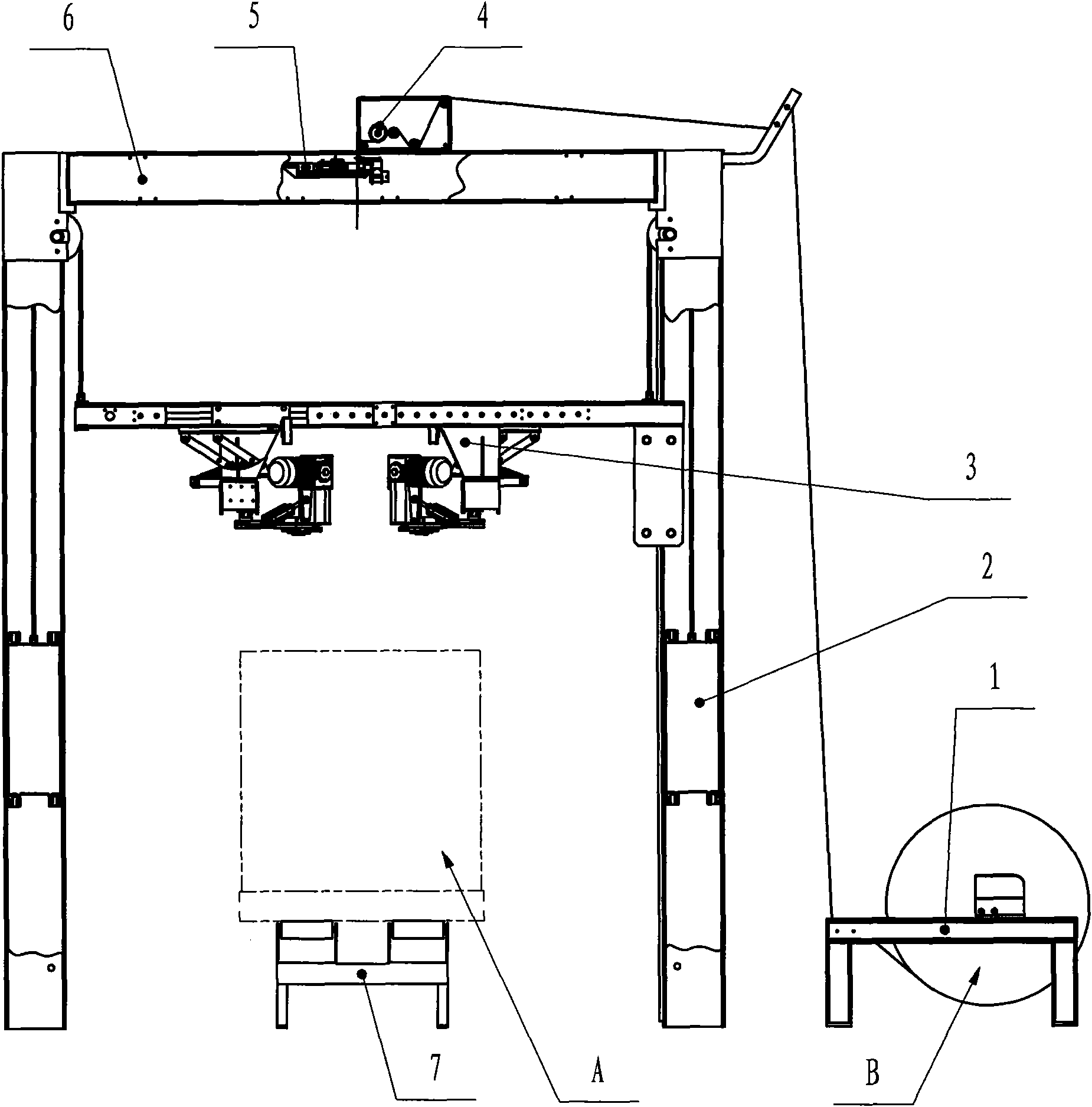

[0012] The specific embodiment of the present invention sees Figure 1 to Figure 7 The universal stretch hood packaging machine includes a film roll support (1), a lifting mechanism (2), a stretching mechanism (3), a film feeding mechanism (4), a film heat sealing and cutting mechanism (5), and a main frame ( 6), the transmission mechanism (7), etc., the main frame (6) is a frame structure with four columns, the film roll support (1) is located outside the main frame (6), and the film feeding mechanism (4) is located on the main frame (6), the film heat sealing and cutting mechanism (5) is located under the film feeding mechanism (4), the transmission mechanism (7) is located on the ground inside the main frame (6), and the lifting mechanism (2) drives the stretching mechanism (3) Make lifting movement along the direction of arrow (2-9).

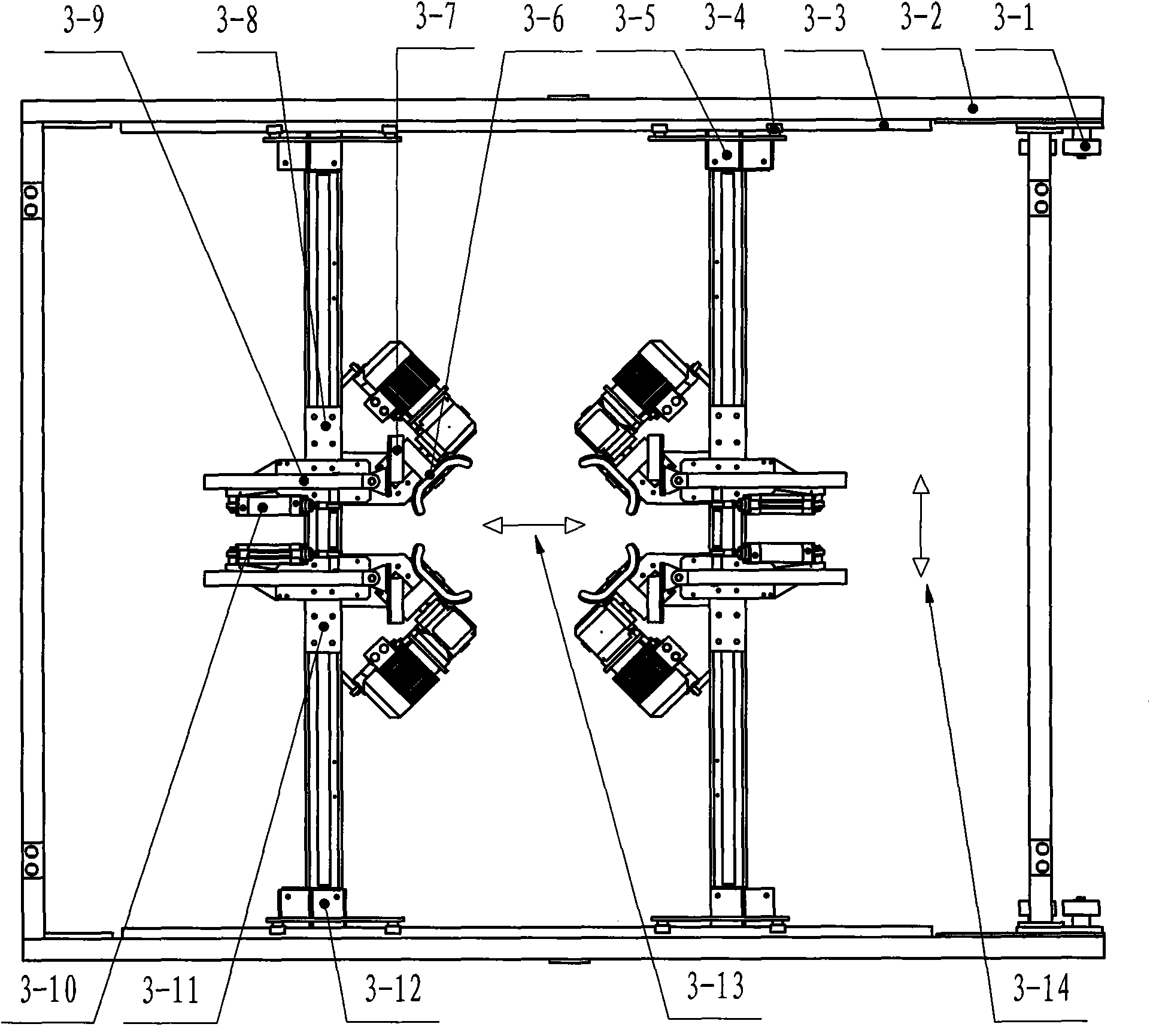

[0013] Stretching mechanism (3) comprises frame (3-2), right movable beam (3-5), left movable beam (3-12), upper sliding frame (3-8), lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com