Automatic feeding device of amorphous alloy strips and discharging control method thereof

An automatic feeding, amorphous alloy technology, applied in the direction of winding strip, thin material processing, transportation and packaging, etc. To avoid excessive accumulation, prolong service life and improve feeding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical features of the present invention more obvious and understandable, the present invention will be further described below in conjunction with specific embodiments.

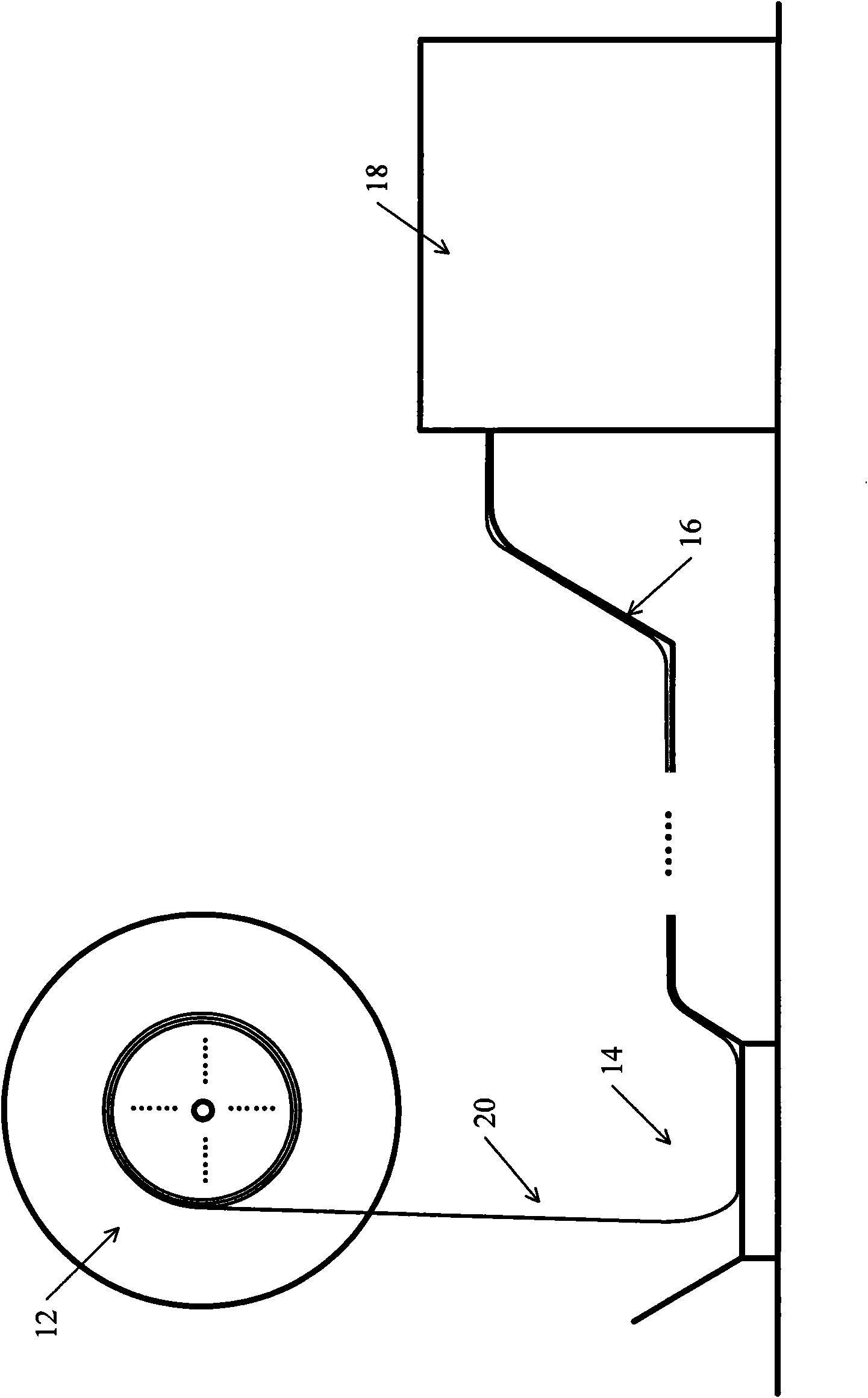

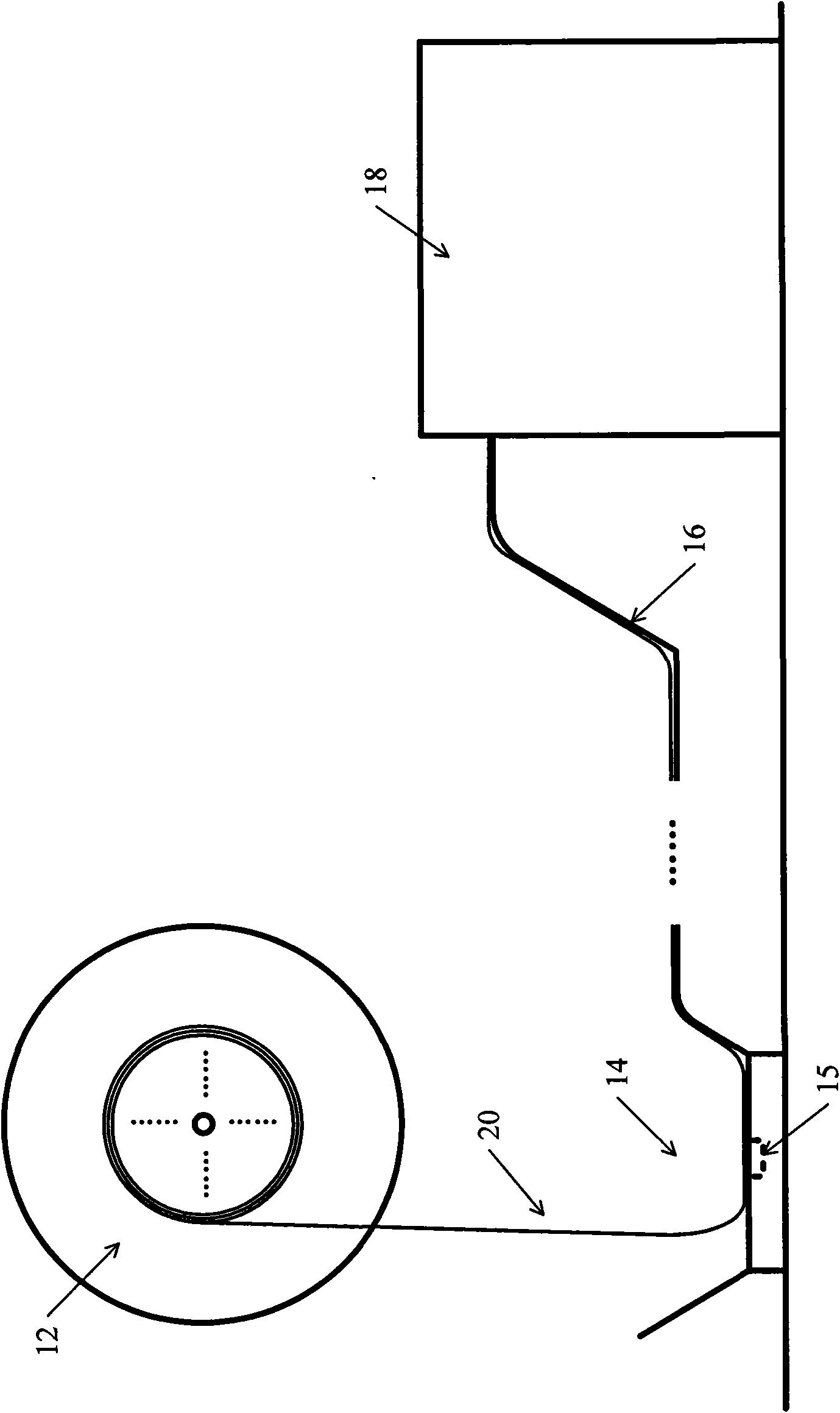

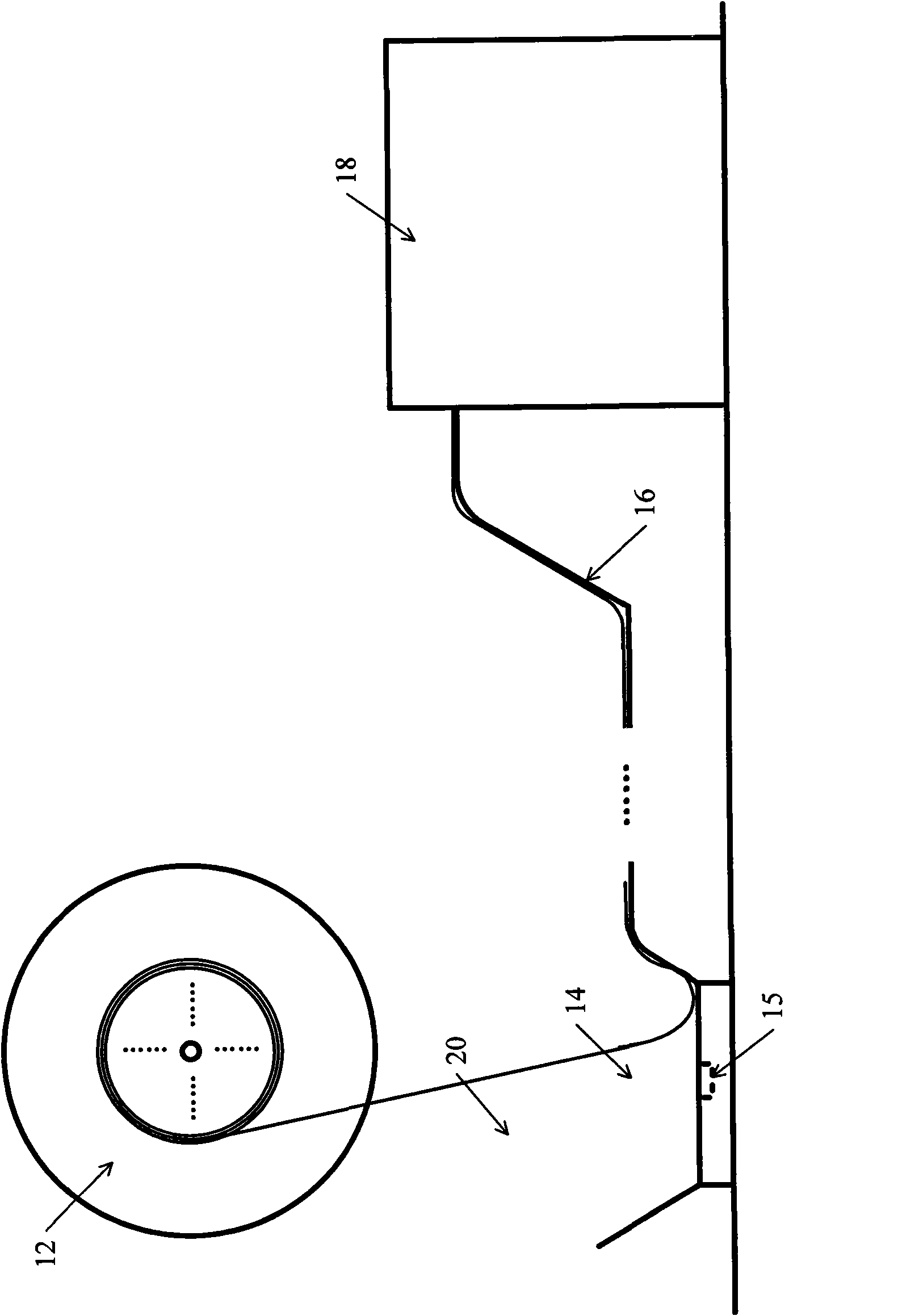

[0027] Please refer to figure 2 , which is a schematic structural view of an automatic feeding device for an amorphous alloy strip provided by an embodiment of the present invention. As shown in the figure, the automatic feeding device includes a feeding device 12, a feeding device 18 and a trough 14 positioned under the discharging device, and is connected to a feed channel 16 between the trough 14 and the feeding device 18, wherein the trough A sensor 15 is installed in 14 to sense the storage situation in the trough 14, and send a drive signal to the discharge device 12 according to the sensed storage situation, so as to drive the discharge device 12 to change the discharge rate.

[0028] In this way, the sensor 15 can be used to sense the stock situation in the trough 14,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com