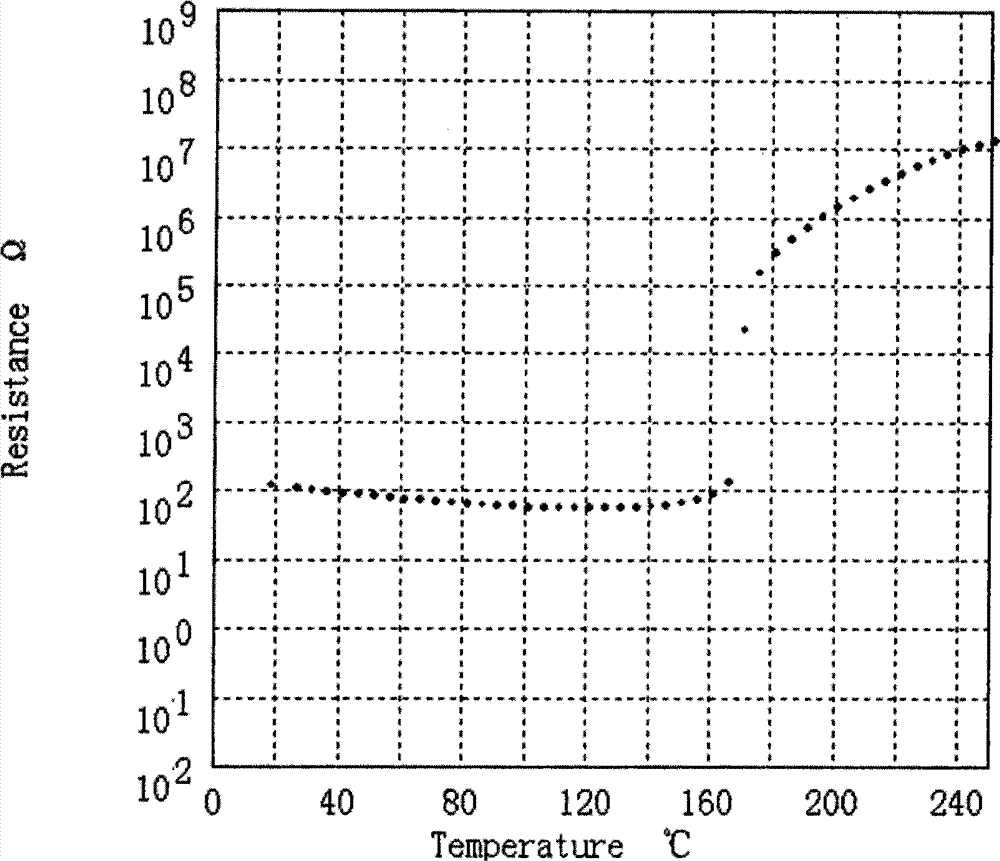

High-Curie-point low-resistivity lead-free PTCR (Positive Temperature Coefficient of Resistance) ceramic material and preparation method thereof

A low-resistivity, ceramic material technology, applied in the BaTiO3-based high Curie point low-resistivity lead-free PTCR ceramic material and its preparation field, can solve the problems of Bi element volatilization, material chemical ratio deviation, and sodium ion loss, etc. Achieve the effects of avoiding grain growth and agglomeration, obvious diffraction peak intensity, and high powder sintering activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

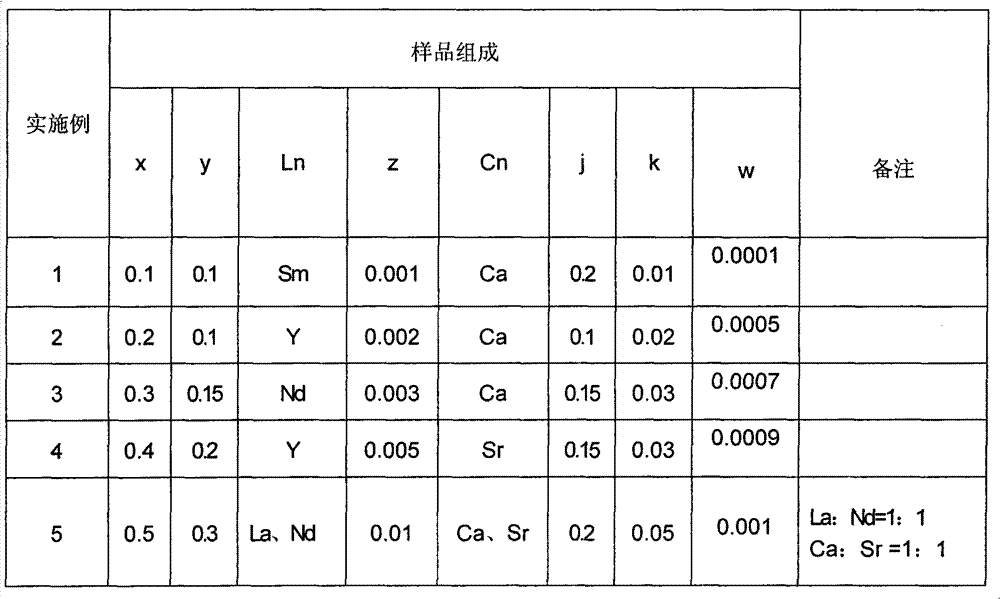

preparation example Construction

[0030] The preparation method of the semiconductor ceramic material involved in the present invention includes batching, polymer in-situ solidification to prepare gel, low-temperature synthesis to prepare nano-powder satisfying chemical dosage ratio, and low-temperature firing to prepare lead-free PTCR ceramics with high Curie point and low resistivity. Specific steps are as follows:

[0031] 1. Prepare the solution

[0032]The initial raw materials are all related metal oxides with a purity of 99.8% and above, such as Bi 2 o 3 、Sm 2 o 3 、Nd 2 o 3 , Y 2 o 3 , La 2 o 3 etc.; or carbonates such as BaCO 3 , CaCO 3 , SrCO 3 、Na 2 CO 3 、K 2 CO 3 etc.; or metal alkoxides such as butyl titanate Si(OC 2 h 5 ) 4 , Ti(OC 4 h 9 ) 4 and other raw materials. Prepare a mixed solution containing Bi, Na, K, Ba, Ti, Ln, Cn, Si, Mn and other ions according to the molar ratio given in formula ①.

[0033] A preferred mode is listed below to illustrate the preparation proce...

Embodiment 1

[0051] 1. Prepare the solution

[0052] Prepare solutions containing Bi, Na, K, Ba, Ti, Sm, Ca, Si, Mn and other ions respectively:

[0053] Press Bi 2 o 3 : nitric acid=1:7 molar ratio, weigh Bi 2 o 3 and nitric acid, dilute with deionized water in nitric acid, and then dilute the diluted solution with Bi 2 o 3 Mix, heat to 80°C, stir, after the reaction is complete, get the 3+ solution, and add ammonia to pH 7;

[0054] Na 2 CO 3 、K 2 CO 3 Deionized water was added to form an aqueous solution.

[0055] By BaCO 3 : Molar ratio of citric acid=1:4, weighing barium carbonate BaCO 3 with citric acid. First, deionized water was added to citric acid to prepare a citric acid solution, and then the citric acid solution was mixed with BaCO 3 After mixing, after the reaction is completed, a 2+ solution, and add ammonia to pH 7;

[0056] Butyl titanate Ti(OC 4 h 9 ) 4 : citric acid=1:1.1 weight ratio, weigh butyl titanate Ti(OC 4 h 9 ) 4 and citric acid, adding de...

Embodiment 2

[0072] 1. Prepare the solution

[0073] Solutions containing Bi, Na, K, Ba, Ti, Y, Ca, Si, Mn ions were prepared respectively.

[0074] Press Bi 2 o 3 : nitric acid=1:6 molar ratio, weigh Bi 2 o 3 and nitric acid, dilute with deionized water in nitric acid, and then dilute the diluted solution with Bi 2 o 3 Mix, heat to 82°C, stir, after the reaction is complete, get the 3+ solution, and add ammonia to pH 8;

[0075] Na 2 CO 3 、K 2 CO 3 Deionized water was added to form an aqueous solution.

[0076] By BaCO 3 : Molar ratio of citric acid=1:3, weighing barium carbonate BaCO 3 with citric acid. First, deionized water was added to citric acid to prepare a citric acid solution, and then the citric acid solution was mixed with BaCO 3 After mixing, after the reaction is completed, a 2+ solution, and add ammonia to pH 8;

[0077] Butyl titanate Ti(OC 4 h 9 ) 4 : citric acid=1:1 weight ratio, weigh butyl titanate Ti(OC 4 h 9 ) 4 and citric acid, adding deionized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com