Pimple-free silk falling method applied to semi-continuous spinning machine

A kind of spinning machine, semi-continuous technology, applied in the field of pimple-free doffing, can solve the problems of high labor intensity of waste pimples, unsafe waste pimples, long doffing time, etc., to avoid the quality problems of pimple silk, reduce The labor intensity of doffing and the effect of reducing height requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A method for doffing without pimples suitable for semi-continuous spinning machines, the steps comprising:

[0030] A. Break the thread;

[0031] B. Use a suction device to suck the filaments into the suction device;

[0032] C. Take out the silk cake;

[0033] D. Fall down.

[0034] The step of taking out the silk cake comprises:

[0035] a. Turn off the electric ingot;

[0036] b. lift bracket;

[0037] c. Uncover the big lid of the drum;

[0038] d. Take silk cake;

[0039] e. Cover the big lid of the drum;

[0040] f pressure bracket

[0041] g. Turn on the electric ingot.

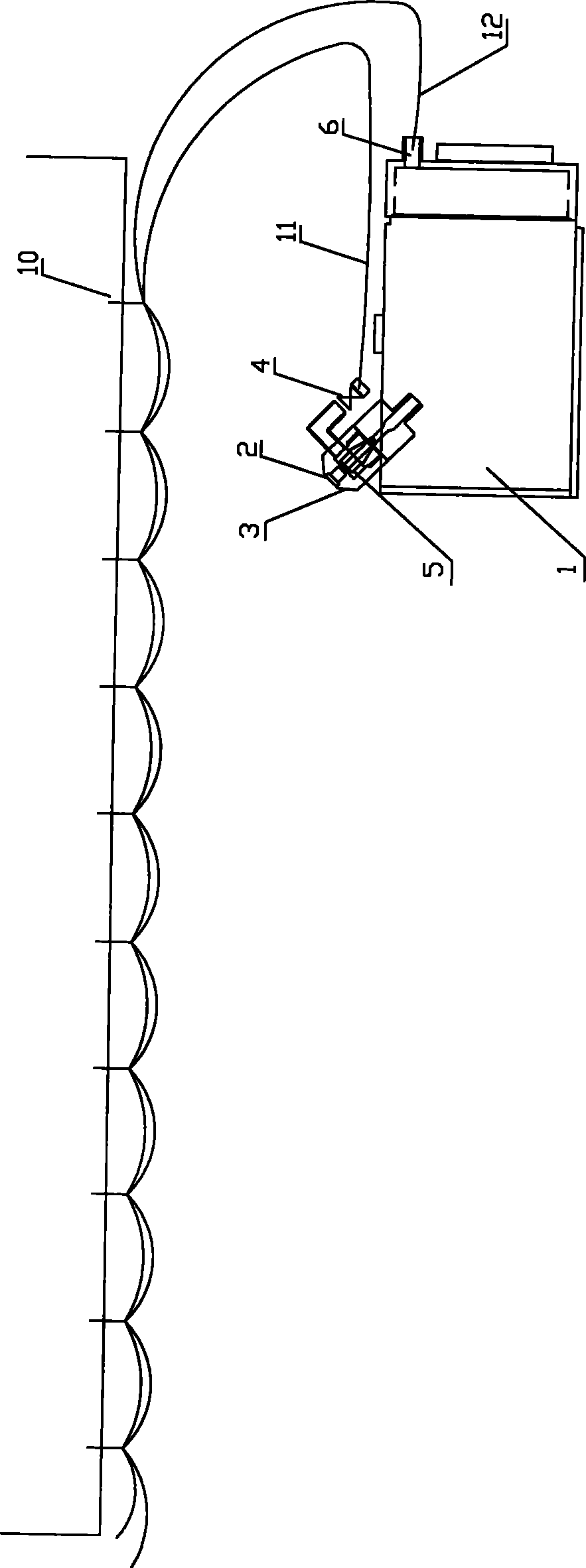

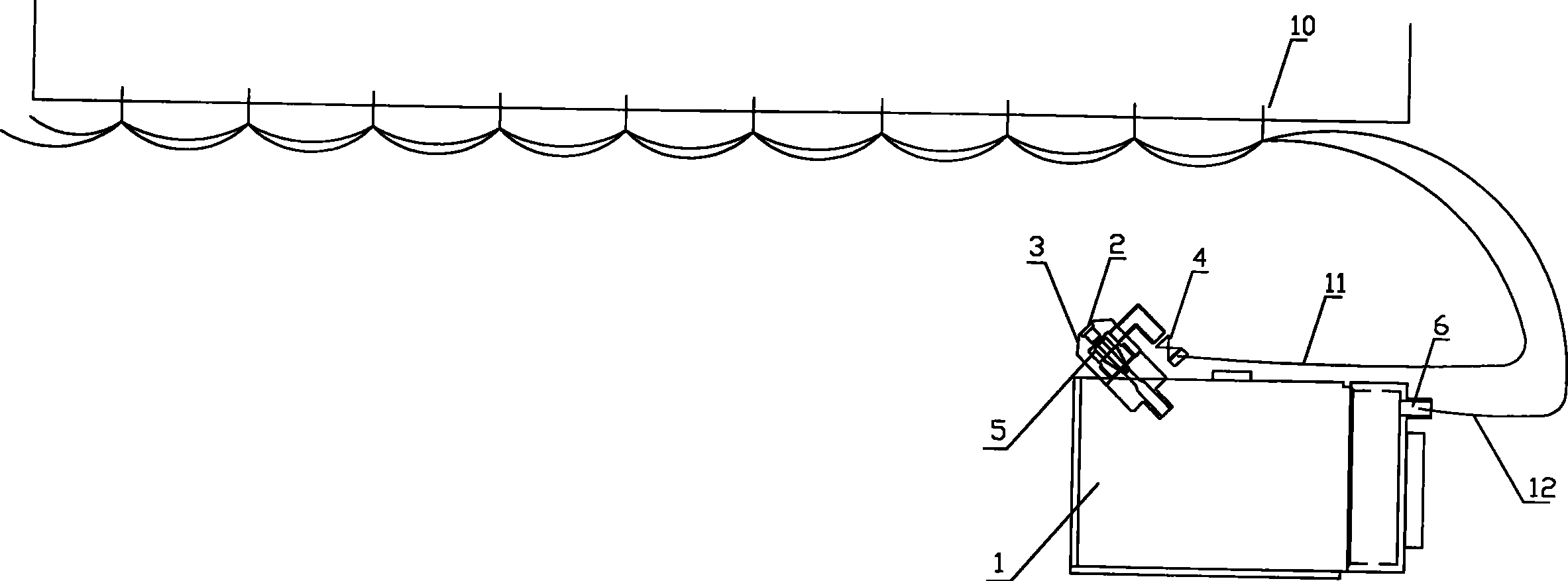

[0042] The silk suction device includes a waste silk bucket and a suction nozzle device connected to the waste silk bucket. The silk suction nozzle device has a suction nozzle and an internal channel 8 connected to the waste silk bucket. The suction nozzle device is connected to an air source The tube 9 communicates with the internal passage 8. The silk suction nozzle device is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com